Air water hammer eliminating silencing valve

A technology for eliminating hammer and gas, applied in the field of gas hammer elimination mute valve, can solve problems such as difficulty in eliminating water hammer noise and destructive force, and achieve the effect of saving metal material cost, reducing running resistance and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

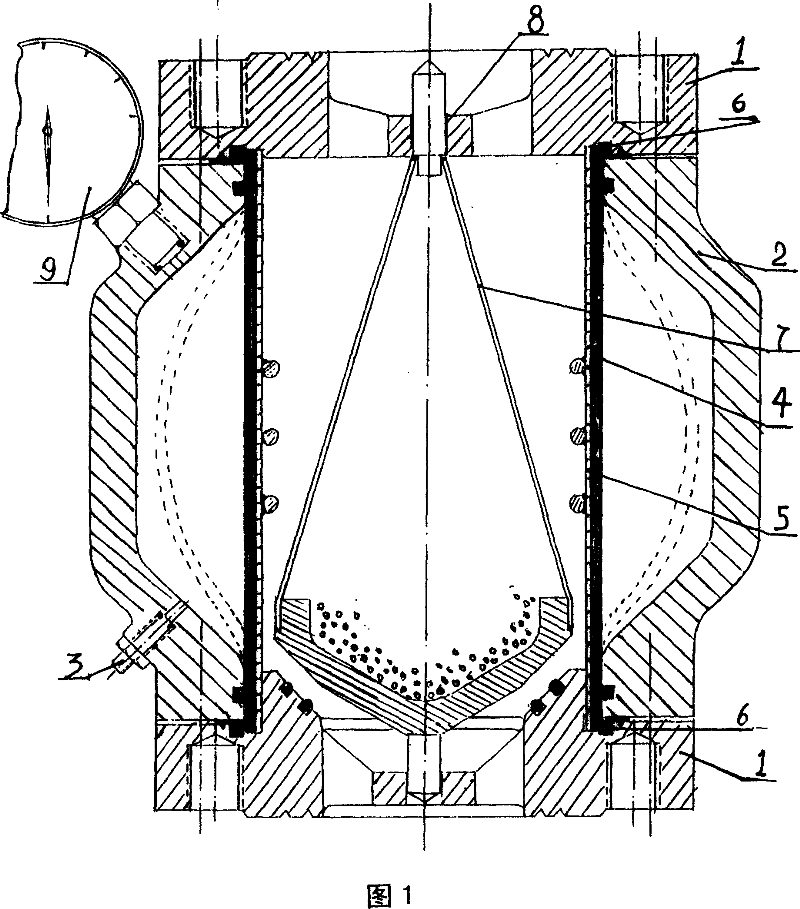

[0019] Example 1: Flange-like check valve

[0020] This embodiment includes a valve housing 2 and a terminal connector 1. The terminal connector 1 includes upper and lower flanges. The valve housing 2 is provided with an air filling nozzle 3, which inflates the valve housing 2 and uses gas to Eliminate water hammer and pipeline noise. The valve housing 2 is axially provided with a retractable air chamber holster 4, the top of the air chamber holster 4 is fixedly connected to the upper flange, and the bottom is connected to the bottom of the valve housing 2 to form an airtight air chamber, which is convenient for processing and manufacturing. Combined with the sealing ring, the processing cost can be reduced. The inner cavity of the valve housing 2 is provided with a double-cone valve core 7, which is equipped with a weight (dry sand) for adjusting the weight. The top and bottom are provided with positioning guide rods, and they are all connected to the guide holes on the end ...

Embodiment 2

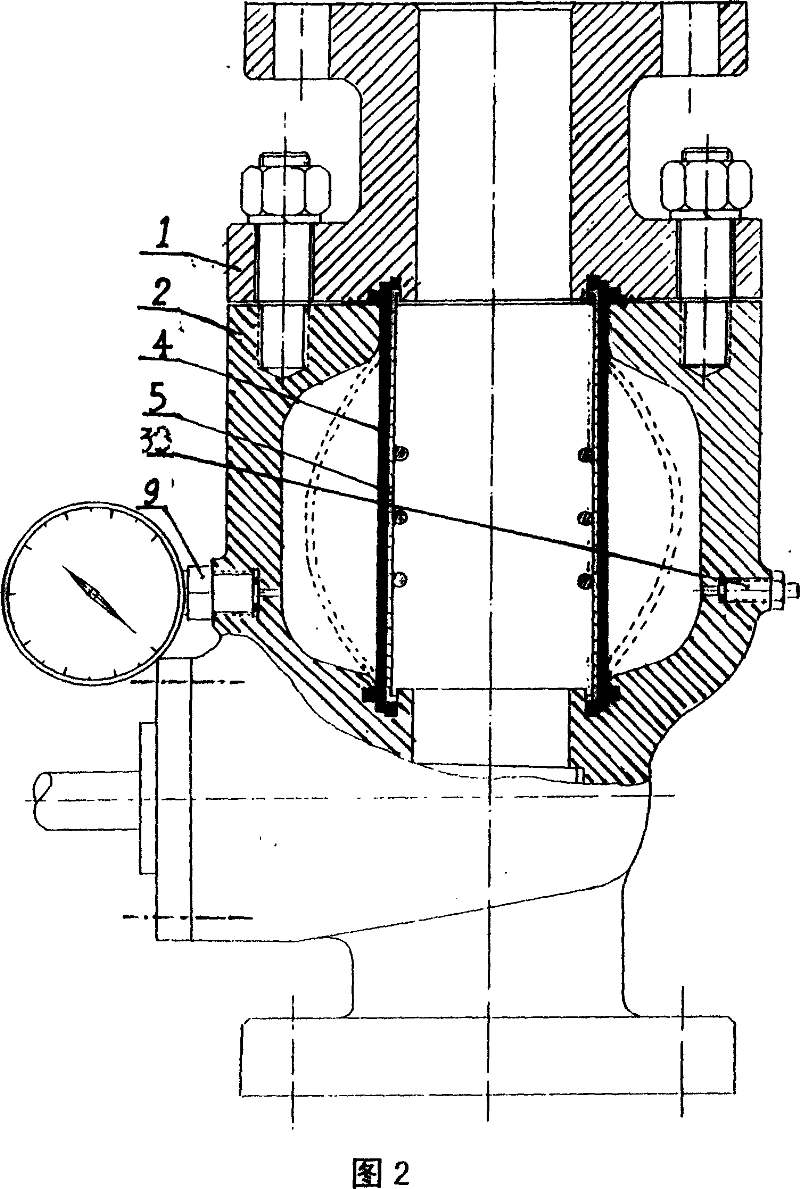

[0023] Embodiment 2: flange type

[0024] This embodiment includes a valve housing 2 and a terminal connector 1, the terminal connector 1 is a short flange tube, the valve housing 2 is provided with an air filling nozzle 3, and the valve housing 2 is axially provided with an air chamber skin Cover 4, the top of the air chamber leather sleeve 4 is fixedly connected with the flange short pipe, and the bottom is connected with the bottom of the valve housing 2 to form a closed air chamber. Inflate with air. The inner wall of the air chamber holster 4 is provided with a balance net cover 5 . The balance net cover 5 is a porous stainless steel plate, the valve housing 2 is provided with a pressure gauge 9, and the upper and lower ends of the air chamber leather cover 4 are provided with a sealing ring 6, which is integrally formed with it.

Embodiment 3

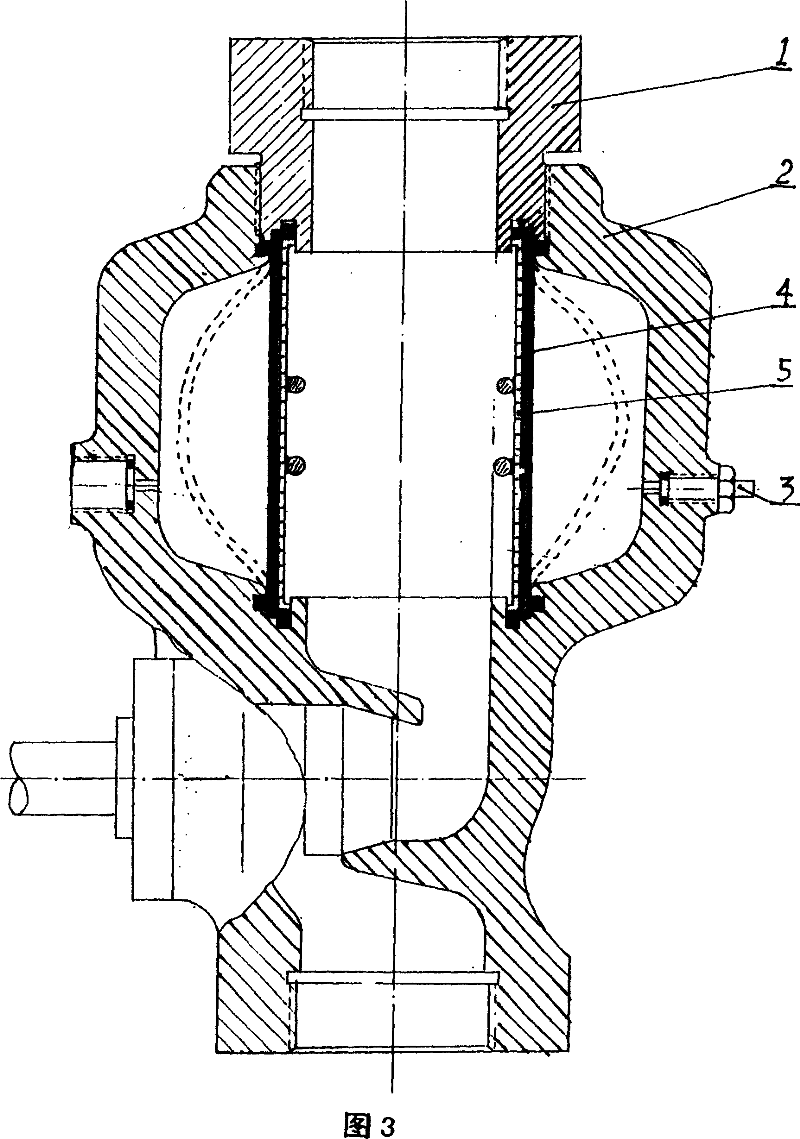

[0025] Embodiment 3: screw type

[0026] This embodiment includes a valve housing 2 and a terminal connecting piece 1, the terminal connecting piece 1 is a short pipe connected by wire (screw type), and the valve housing 2 is axially provided with a retractable air chamber holster 4, the air chamber Holster 4 top is affixed with flange short pipe, and the bottom is connected with valve housing 2 bottoms, has formed airtight air chamber, and air filling nozzle 3 communicates with airtight air chamber, can give (supplement) fill air in it. The inner wall of the air chamber holster 4 is provided with a balance net cover 5 . The balance net cover 5 is a porous stainless steel plate, and the upper and lower ends of the air chamber leather cover 4 are provided with sealing rings 6, and are integrally formed with it. It is mainly used for noise reduction and is used on low-pressure pipe sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com