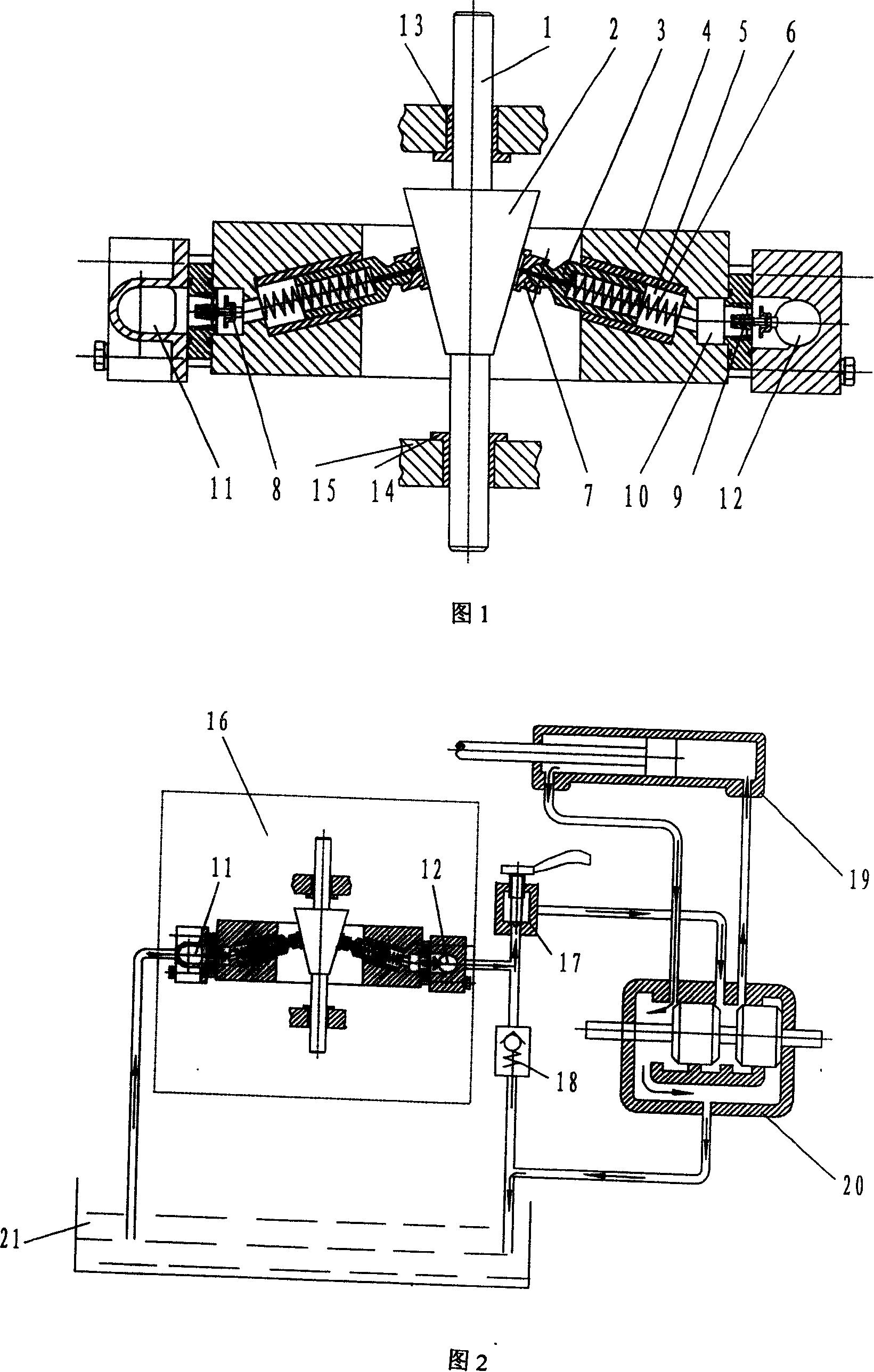

Method and apparatus for converting mechanical energy into fluid pressure energy

A technology of fluid pressure and mechanical energy, applied in the field of converting mechanical energy into fluid pressure energy, can solve the problem of large flow pulsation in single-cylinder structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: The device of the present invention is a hydraulic power system used as a hydraulic power source.

[0015] On the main structure 16 of the energy conversion device of the present invention, the input ends of the flow control valve 17 and the overflow valve 18 are connected to the output end of the fluid discharge manifold 12, and the hydraulic cylinder 19 and the flow control valve 17 are connected with the direction control valve as required. 20 is communicated, and the oil return port of overflow valve 18, direction control valve 20 and fluid suction manifold 11 input end are communicated with oil tank 21, form the hydraulic power system that the device of the present invention uses as hydraulic power source, have realized invention through experimental result Purpose.

Embodiment 2

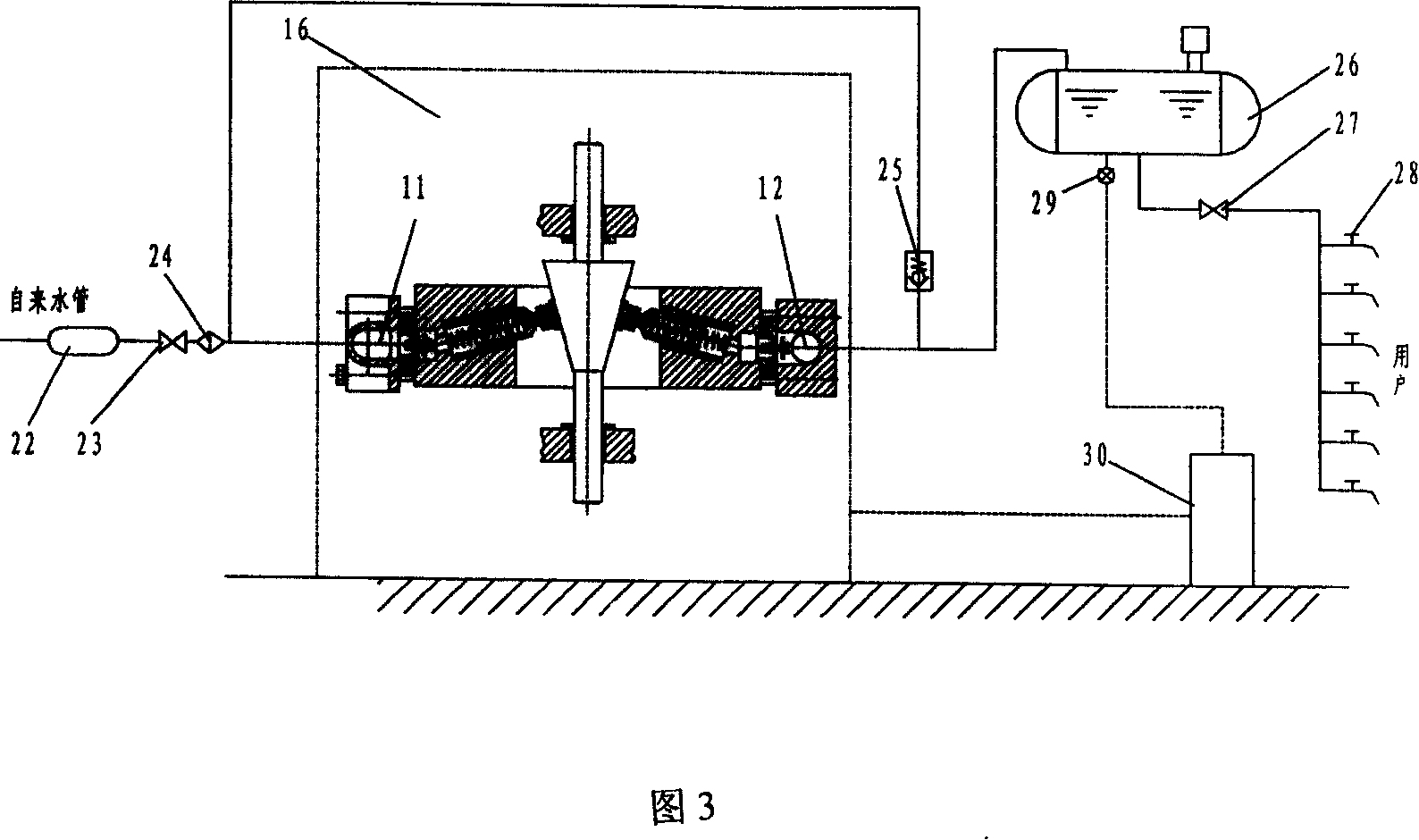

[0016] Embodiment 2: The device of the present invention is used as a high-efficiency urban building water supply system for internal combustion plunger pumps.

[0017] On the main structure 16 of the energy conversion device involved in the present invention, the input end of the fluid suction manifold 11 is connected with the low-level water reservoir 22, the water inlet switch valve 23, the water filter 24, etc. according to the prior art process, and the fluid is discharged The output end of the collecting pipe 12 is connected with the pressure-limiting safety valve 25, the high-level water storage device 26, the user switch main valve 27, the user switch sub-valve 28, etc., and a water level sensor 29 and a control cabinet 30 are installed in the system to form a high-efficiency system. The water supply system for urban buildings provides stable and applicable water pressure flow according to the needs of residents and users. After experiments, under the condition of 10 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com