Alloy gas chromism film material

An aerochromic and thin-film material technology, applied in optical components, optics, instruments, etc., can solve the problems of high cost of rare earth alloy thin films, achieve obvious energy-saving effects, improve durability, and reduce secondary radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

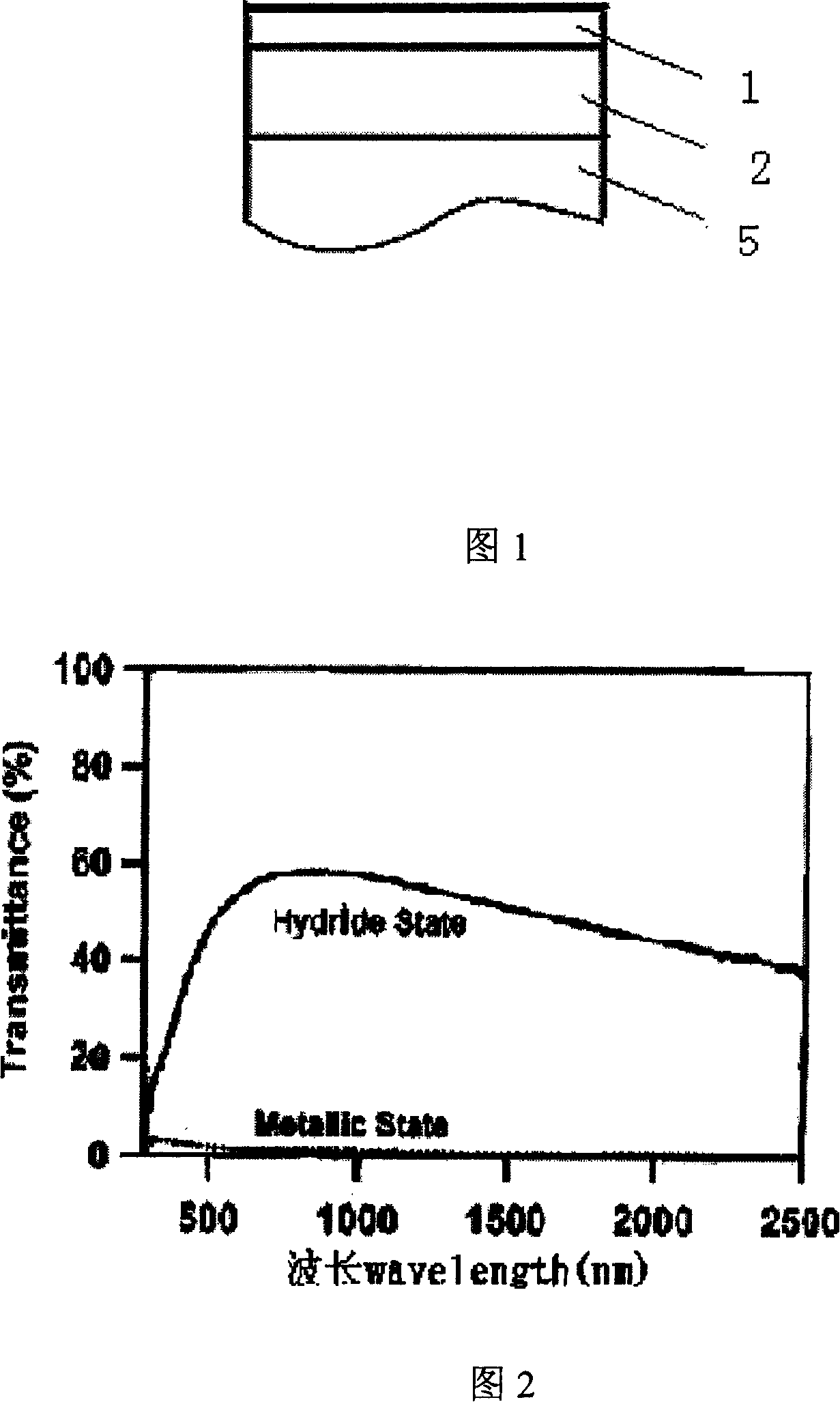

[0031] In this embodiment, the glass substrate 5 is covered with an alloy aerochromic film. The film layer of described alloy aerochromic thin film is made up of the alloy layer of 40nm thickness and the palladium (Pd) layer of 5nm thickness (see Fig. 1), wherein the molar ratio of alloy layer Mg, Ni is 20: 1, passes into hydrogen In the state of (4 V / V%), the transmittance of the film was measured to be 20% with light of wavelength λ=670nm.

Embodiment 2

[0033] In this embodiment, the glass substrate 5 is covered with an alloy aerochromic film. The film layer of described alloy aerochromic thin film is made up of the alloy layer of 40nm thickness and the palladium (Pd) layer of 5nm thickness (see Fig. 1), wherein the molar ratio of alloy layer Mg, Ni is 2.5: 1, passes into hydrogen In the state of (4V / V%), the transmittance of the film was measured to be 46% with light of wavelength λ=670nm.

Embodiment 3

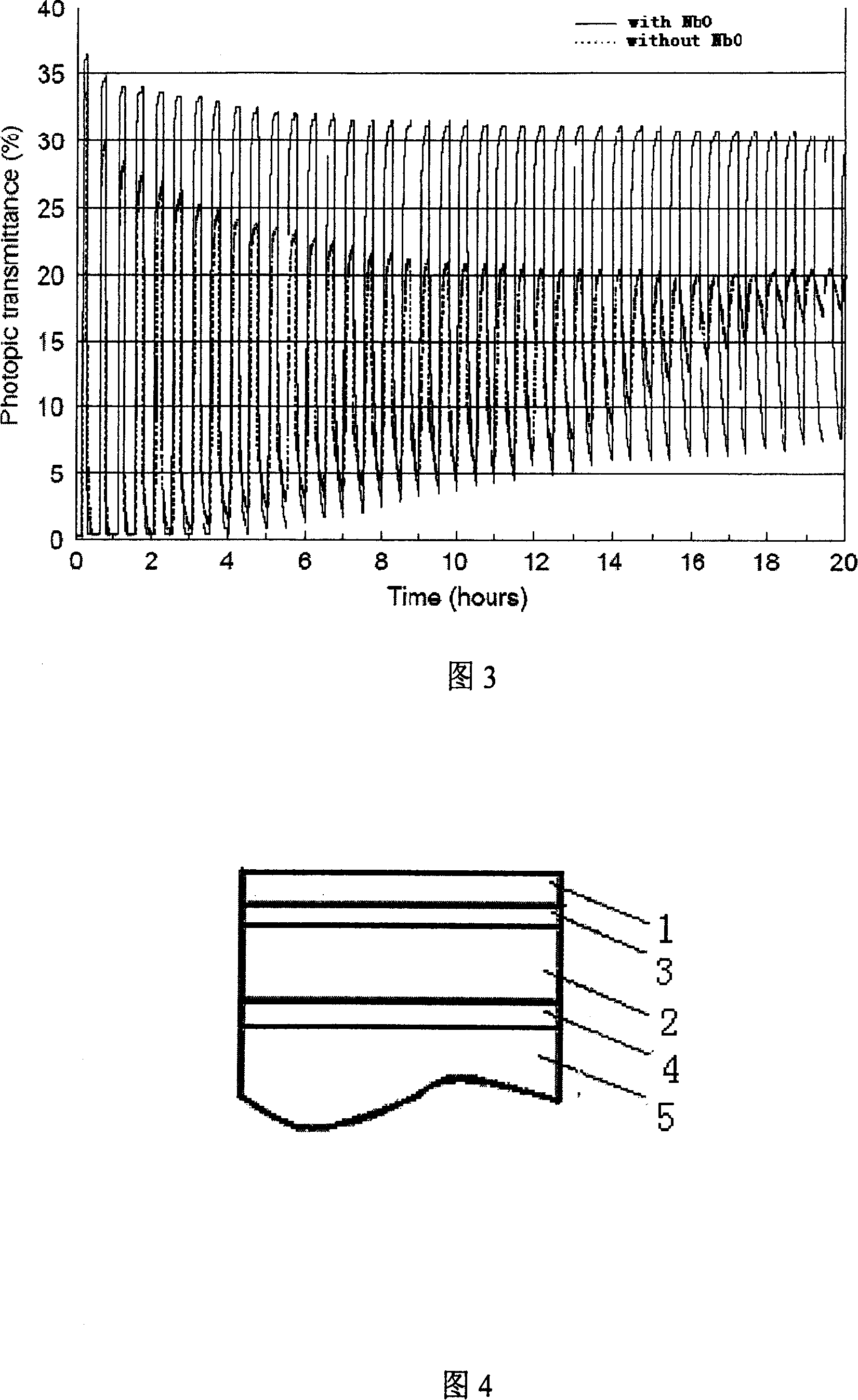

[0035] In this embodiment, the glass substrate 5 is covered with an alloy aerochromic film. The film layer of described alloy aerochromic thin film is made up of the alloy layer of 40nm thickness and the palladium (Pd) layer of 5nm thickness (see Fig. 1), wherein the molar ratio of alloy layer Mg, Ni is 5: 1, passes into hydrogen In the state of (4V / V%), the transmittance of the film was measured to be 72% with light of wavelength λ=670nm. The comparison chart of the transmittance of the film in the high and low hydrogen states in the wavelength range of 340-2500nm is shown in Fig. 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com