Combined hollow floor slab comprising steel, concrete and hung fireproof ardealite plate and its production process

A production method and technology of reinforced concrete, applied in fire prevention, floor slabs, building components, etc., can solve the problems of not fully exerting the mechanical properties of steel and concrete, large surface area for rust prevention and fire prevention, and inability to save steel consumption, etc. Achieve the effect of avoiding grid deformation and welding stress, good rigidity and strength, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

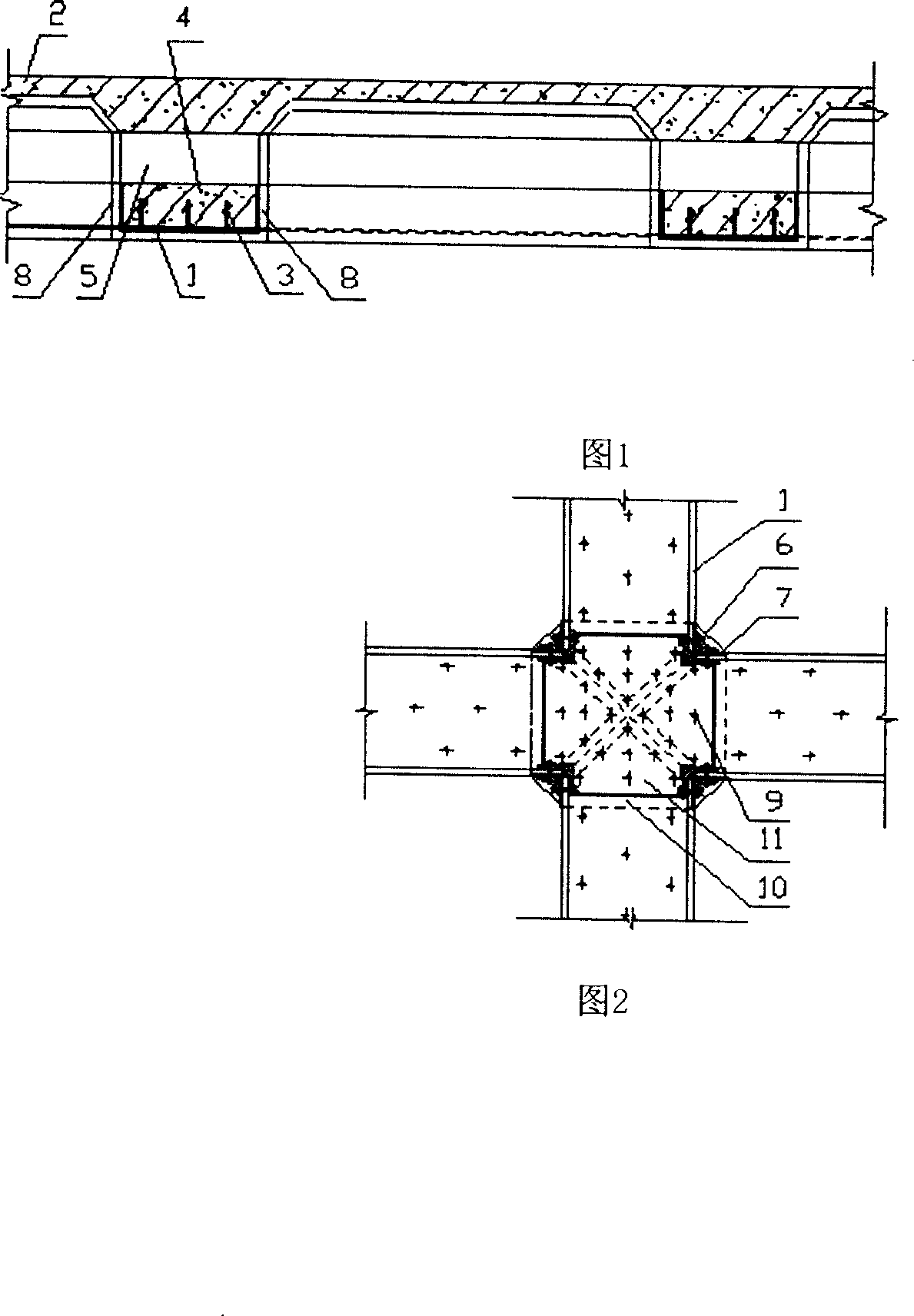

[0017] Embodiment of the present invention: as shown in accompanying drawing 1, it is connected by reinforced concrete shear key (5) by the lower rib grid plate of more than 5 lower floors and the upper rib grid plate of the upper floor, the lower rib grid There are no less than 5 grids in each direction of the grid plate. When manufacturing, the grid size of the lower rib grid plate can be divided according to the geometric size of the floor slab. The upper rib grid plate is a cast-in-place reinforced concrete densely-ribbed well-shaped slab (2). For each hollow position of the reinforced concrete densely ribbed tic-tac-toe slab (2), first use phosphogypsum hollow wedges to fill the hollow positions. After the reinforced concrete densely ribbed tic-tac-toe slab (2) is formed, remove the hollow wedges to form Empty belly; the cast-in-place reinforced concrete densely ribbed slab (2) works together with the lower rib grid slab of the hollow large slab floor through the reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com