Manufacture of laminated piezoelectric ceramic element

A technology for piezoelectric ceramic components and manufacturing methods, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., and can solve the problem of piezoelectric property degradation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

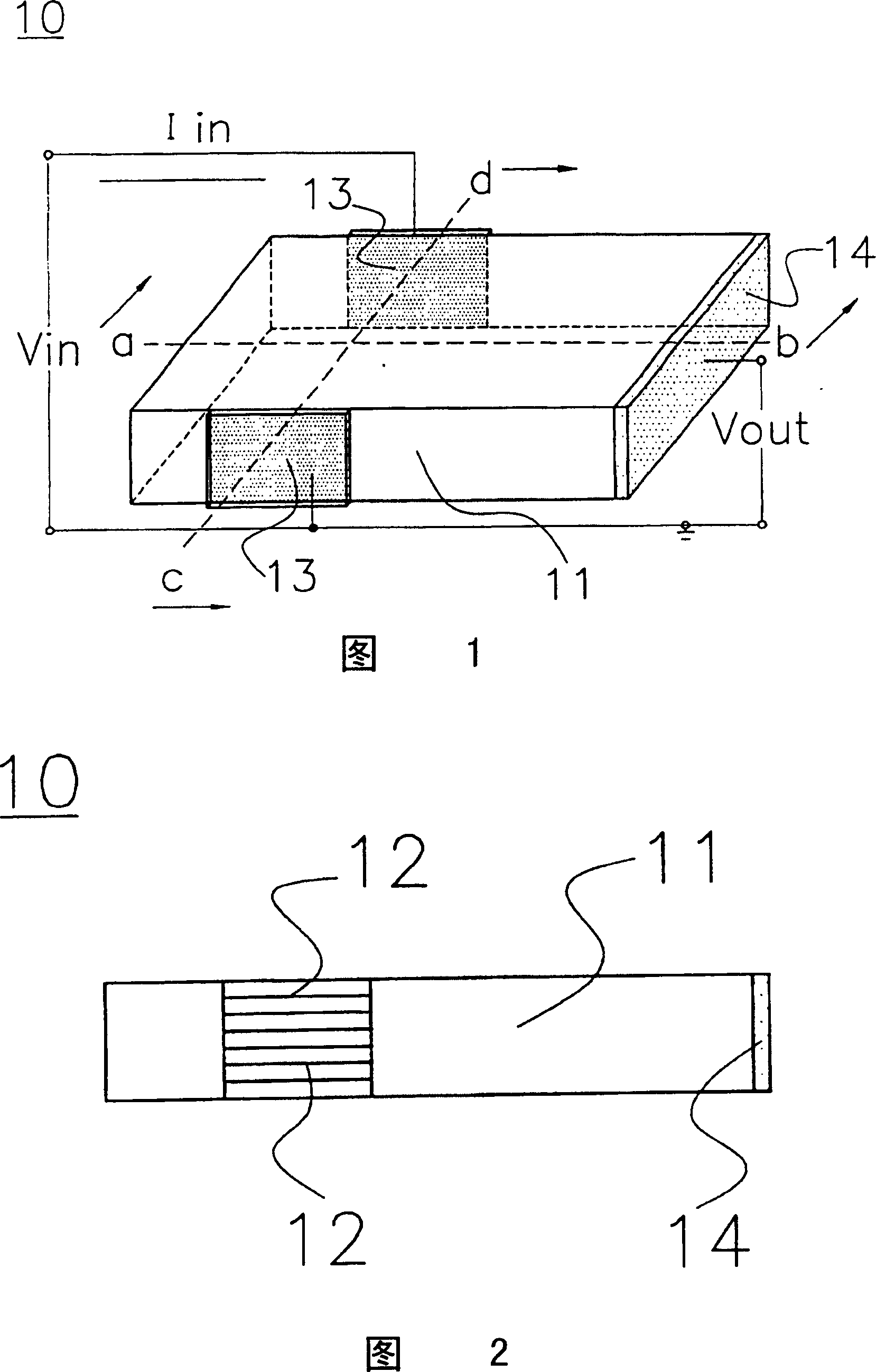

Embodiment 1

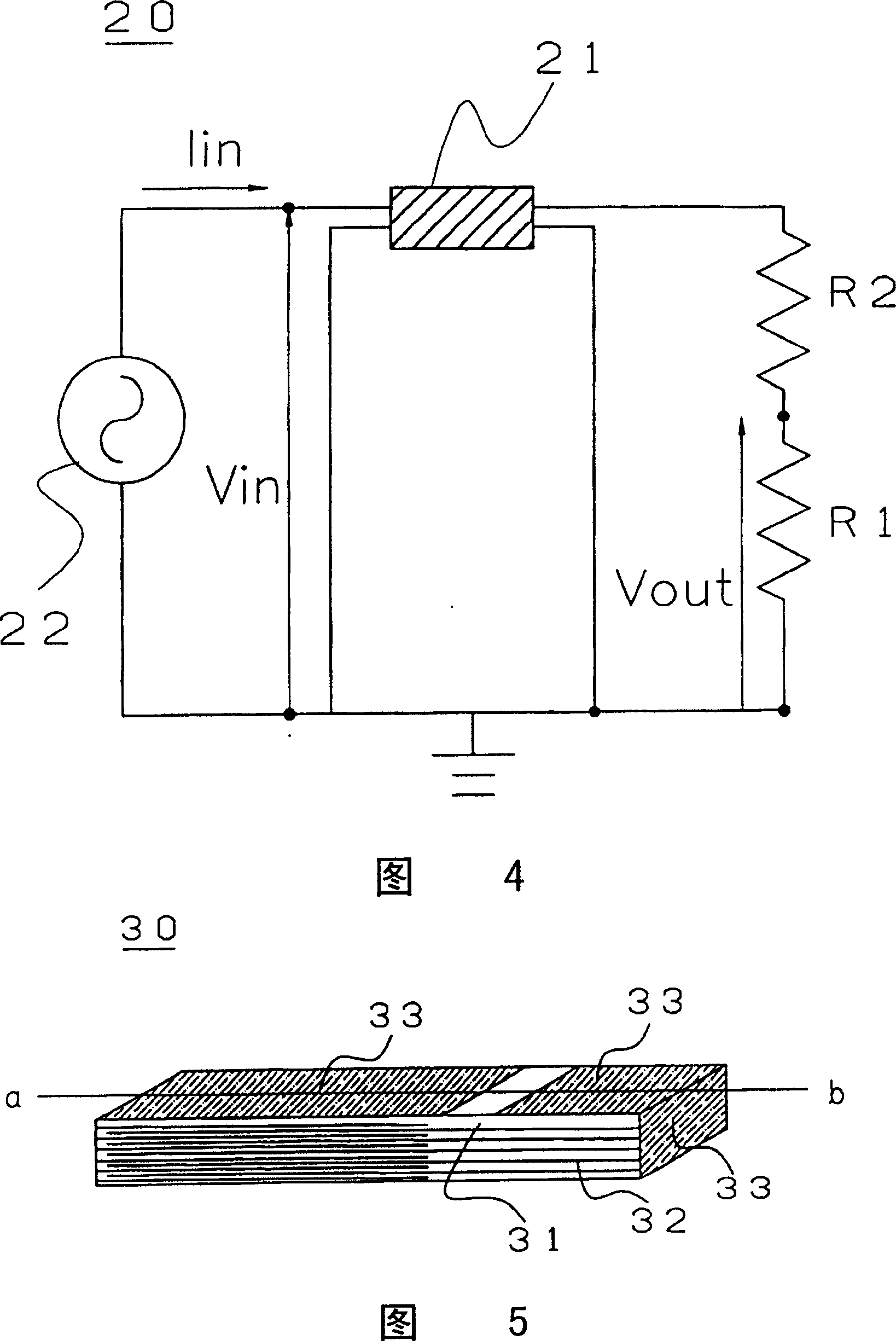

[0049] First, PbO was prepared as the initial raw material 4 ,TiO 2 , ZrO 2 , SnO 2 , Sb 2 o 3 and MnCO 3 .

[0050] Then, in order to obtain Pb((Sn 1 / 3 Sb 2 / 3 ) 0.10 Zr 0.45 Ti 0.45 )O 3 The main component of the composition contains 0.06% Mn( as an additive by weight of the piezoelectric ceramics. The above raw materials are weighed and wet-mixed with a ball mill. The above-mentioned mixture is dehydrated and dried, and the temperature is 820°C for 2 hours. Calcined and crushed to obtain calcined powder.

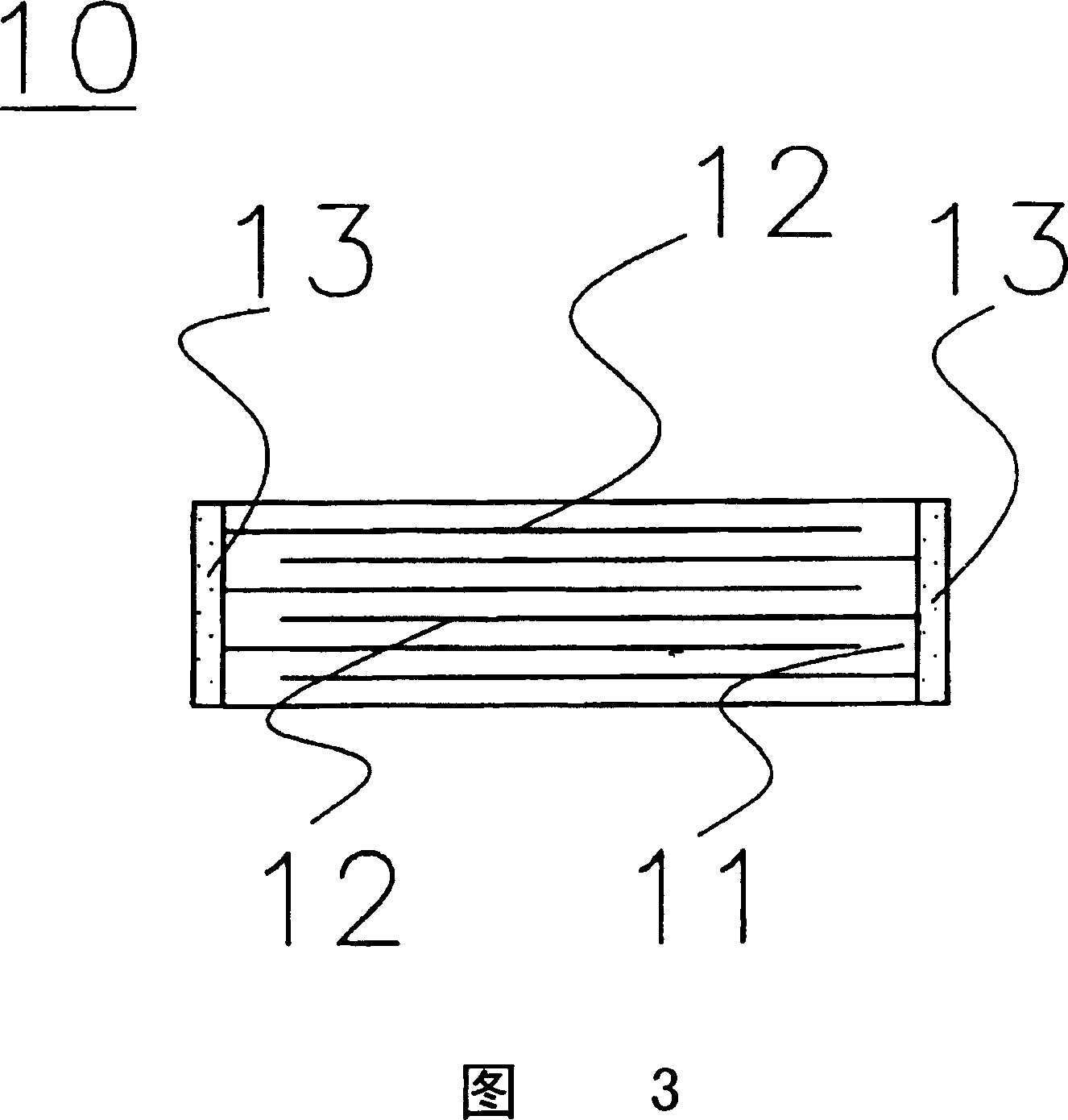

[0051] Next, additives such as a propylene-based organic binder, an organic solvent, and a plasticizer were added to the calcined powder, and wet-mixed with a ball mill to obtain a slurry. This slurry was shaped by a doctor blade method to produce a ceramic green sheet with a thickness of about 100 μm.

[0052] On this ceramic green sheet, a conductive paste containing Ag / Pd conductor was applied by screen printing, and dried so that the thickness after sinteri...

Embodiment 2

[0082] First, Pb was prepared as the initial raw material 3 o 4 、TiO 2 , ZrO 2 and SrCO. Then, in order to get Pb 0.98 Sr 0.02 (Zr 0.45 Ti 0.55 )O 3 The above-mentioned piezoelectric ceramic composition was weighed and wet-mixed with a ball mill.

[0083] The mixture was dehydrated and dried, calcined at 800° C. for 2 hours, and pulverized to obtain a calcined powder.

[0084] Next, additives such as a propylene-based organic binder, an organic solvent, and a plasticizer were added to the calcined powder, and wet-mixed with a ball mill to obtain a slurry.

[0085] Then, the slurry was shaped by a doctor blade method to form a ceramic green sheet having a thickness of about 40 μm.

[0086] On this ceramic green sheet, an Ag / Pd-containing conductive paste was applied by screen printing and dried so that the thickness after sintering became 1.0 to 3.0 μm, thereby obtaining a ceramic green sheet on which an internal electrode layer was formed. Then, the ceramic green s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com