Polymer micro chip hot bonding package method based on peltier heat circulation principle

A packaging method and polymer technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of limited selection of cover and substrate materials, difficulty in ordinary laboratories, and expensive production costs, etc., to achieve heating The effect of shortened time, simple mechanical structure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

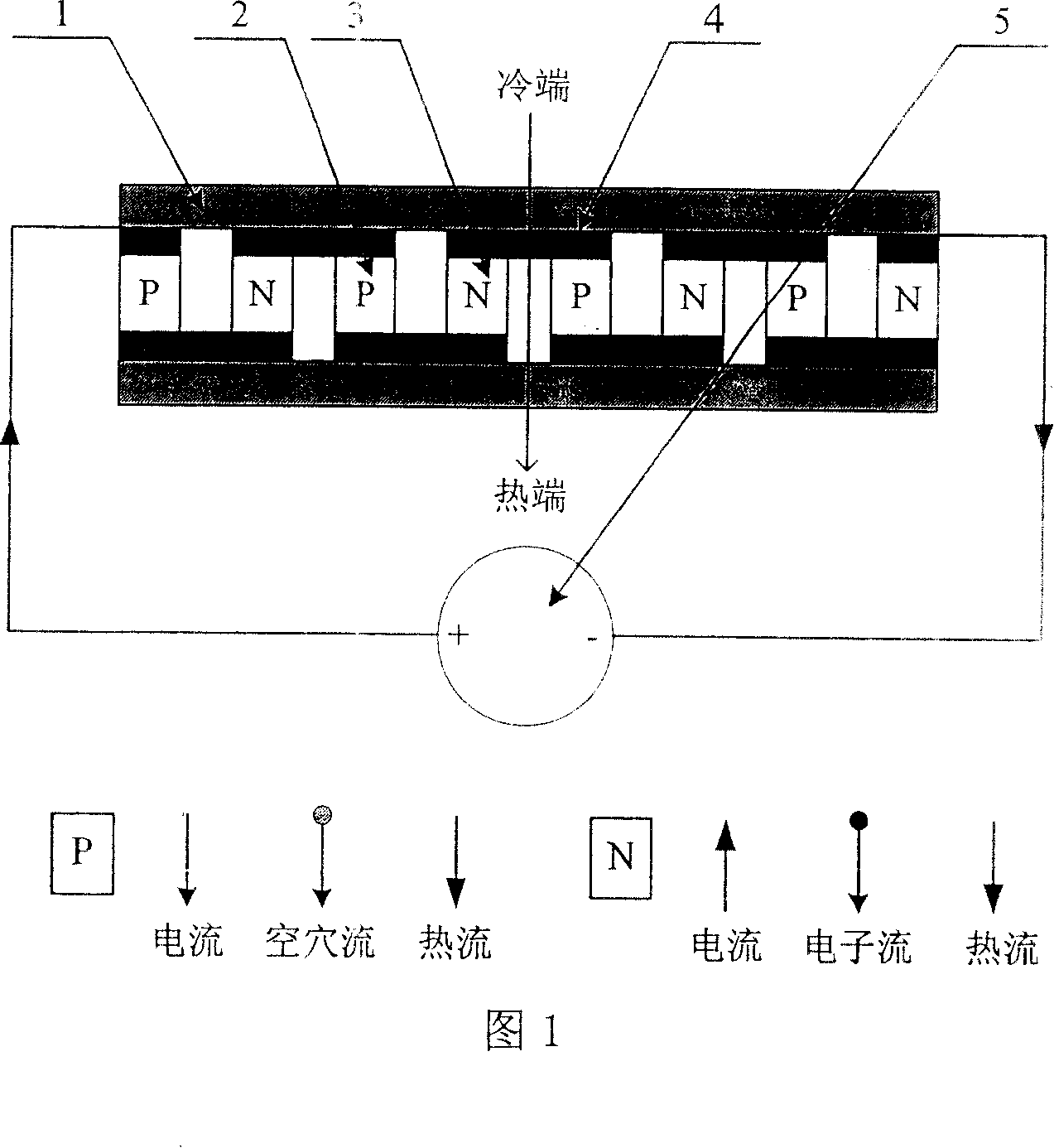

[0022] As shown in Figure 1, the principle of the present invention is as follows:

[0023] It is heated by a semiconductor thermoelectric cooler. Semiconductor thermoelectric coolers generally use bismuth tellurium compounds. Typically, P-type bismuth-tellurium blocks 2 and N-type bismuth-tellurium blocks 3 are alternately placed, the electrical connection is serial connection, the connecting wire is copper, and the thermal connection is parallel connection, which is completed by two ceramic substrates 1 . On the P-type bismuth-tellurium block 2 , the hole current carries the heat flow to move downward, and on the N-type bismuth-tellurium block 3 , the electron flow carries the heat flow to move downward. Since bismuth-tellurium compounds are poor conductors of heat but good conductors of electricity, the device is thermally efficient. Since no P-N junction is used, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com