Fluid bearing device and disk recording reproducer

A fluid bearing and regenerative device technology, which is applied in the recording of information on the magnetic disk, magnetic recording, magnetic recording, etc., can solve the problems that the oil 42 cannot be coated, the effect is insufficient, and the wear is accelerated, so as to achieve high reliability and realize The effect of stabilization and realization of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

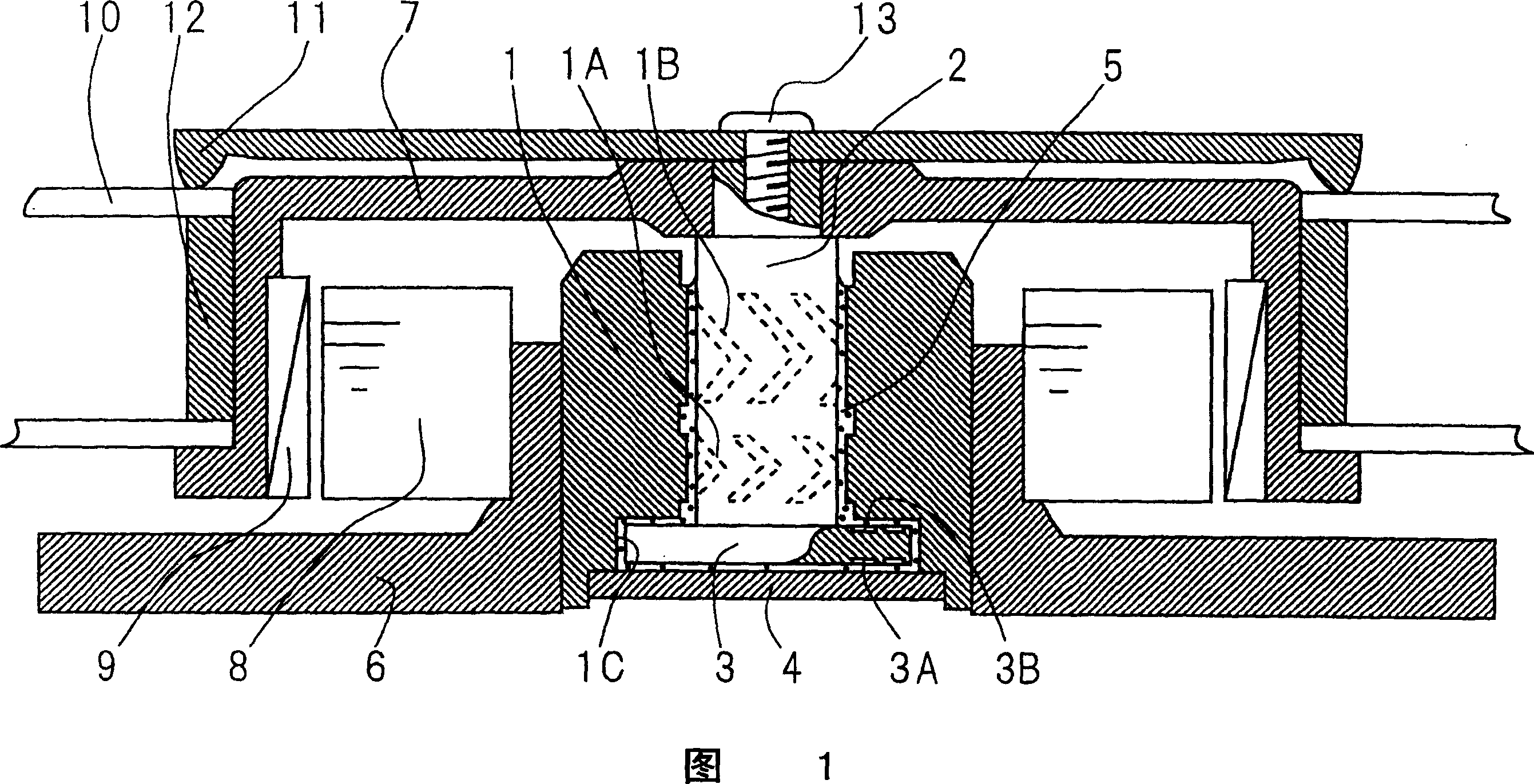

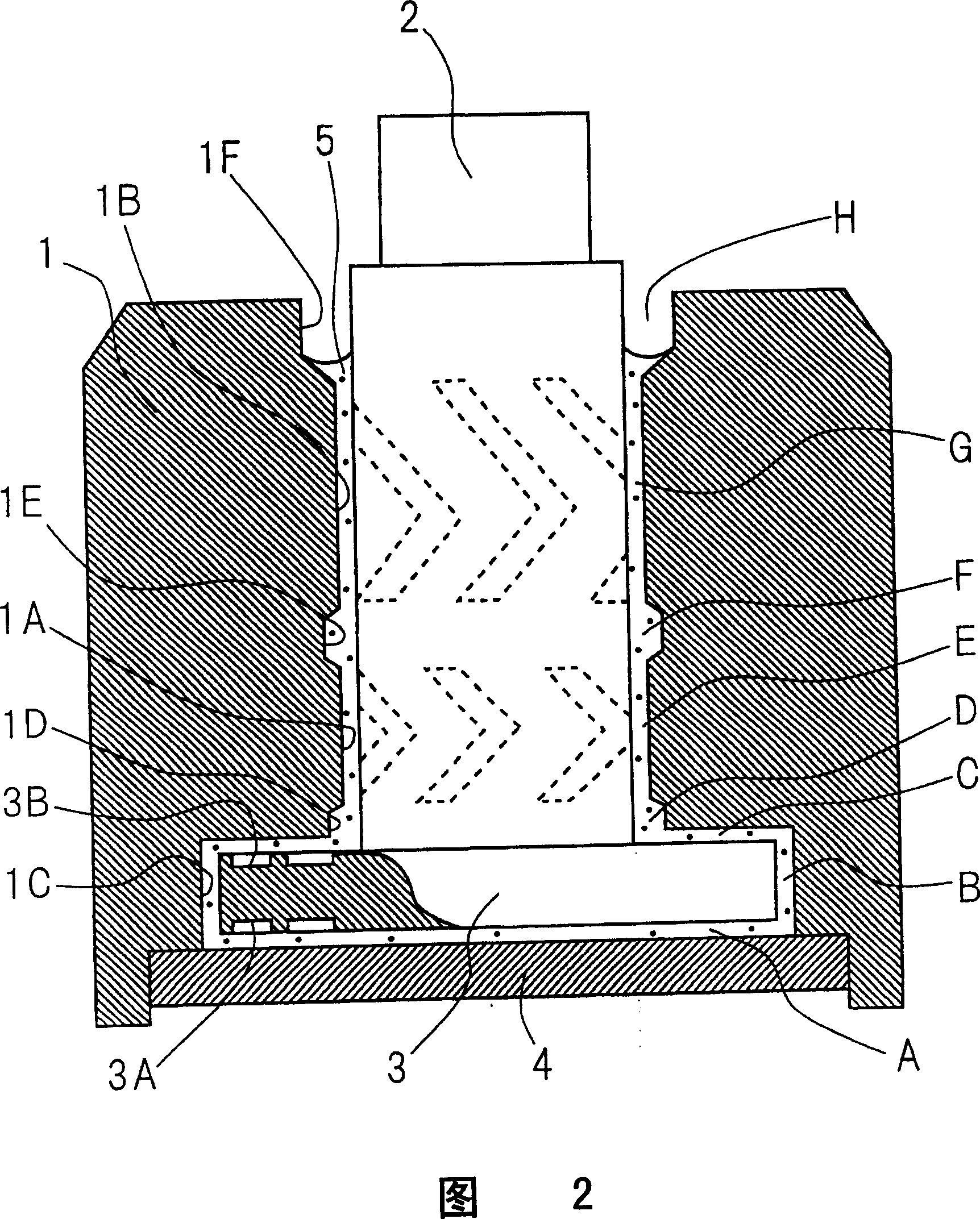

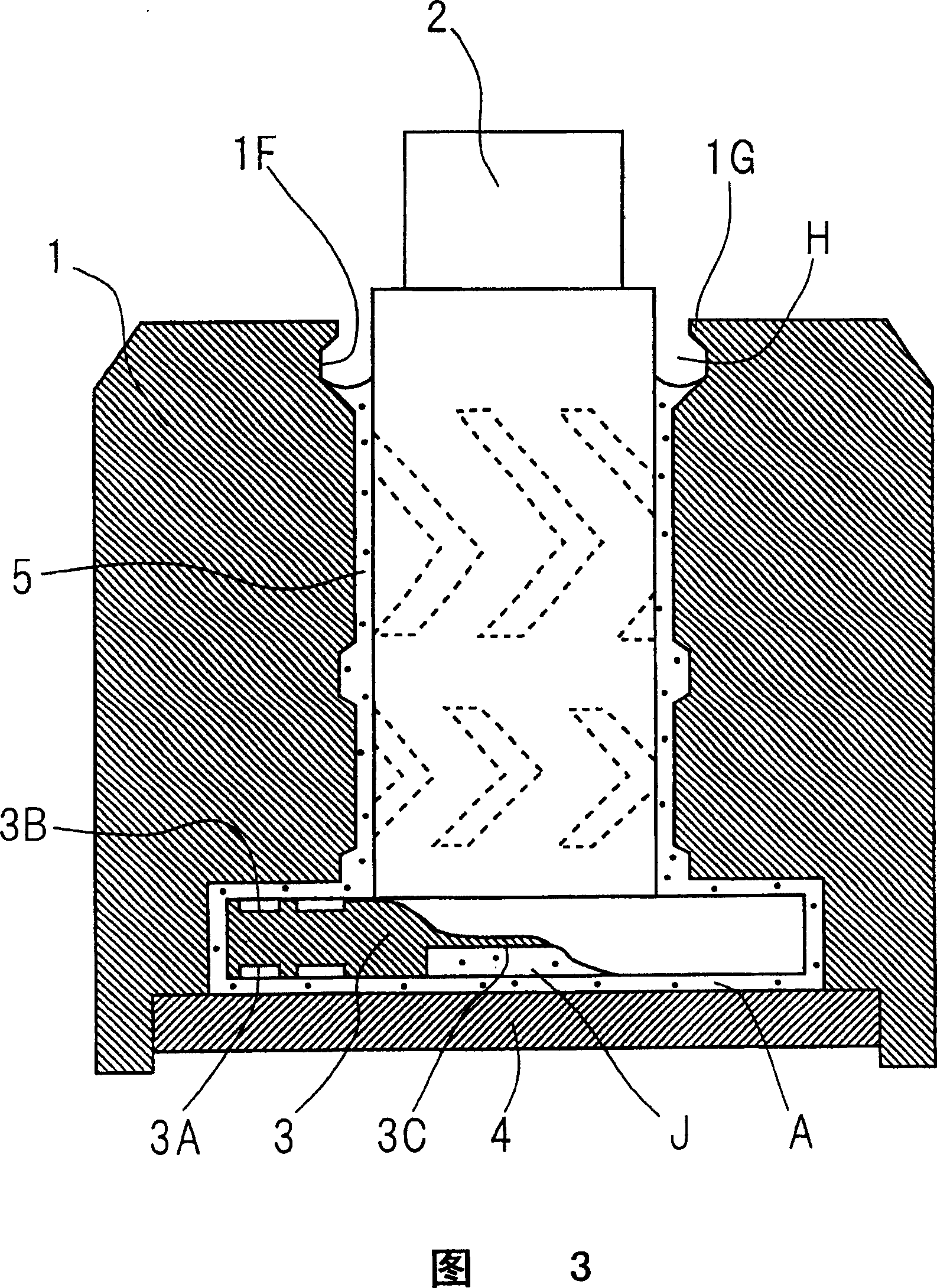

[0035] 5 is a cross-sectional view of a magnetic disk recording and reproducing device according to an embodiment of the present invention. The disk recording and reproducing device includes: a base 6 , a fluid bearing device, a hub 7 , a stator 8 , a magnet 9 , a disk 10 , a holder 11 , a partition 12 , an upper cover 14 , a rotating arm 15 and a pillar 16 . The fluid bearing device has: a sleeve 1 , a shaft 2 , a flange 3 and a thrust plate 4 . The base 6 and the upper cover 14 are fitted together to form a box-shaped frame. At this time, the base 6 and the upper cover 14 seal the inside of the frame to prevent foreign matter such as dust from mixing in from the outside. The sleeve 1 is inserted into the hole of the base 6 for fixing. The thrust plate 4 seals the lower open end of the sleeve 1 . The thrust plate 4 is fixed to the lower open end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com