Magnetic resistance head and making method thereof

A magneto-resistive and magnetic head technology, which is applied in the manufacture of magnetic flux-sensitive magnetic heads, magnetic recording heads, magnetic recording, etc., can solve problems such as poor contact, difficulty in aligning MR films with contact holes, etc., and achieve high yield and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

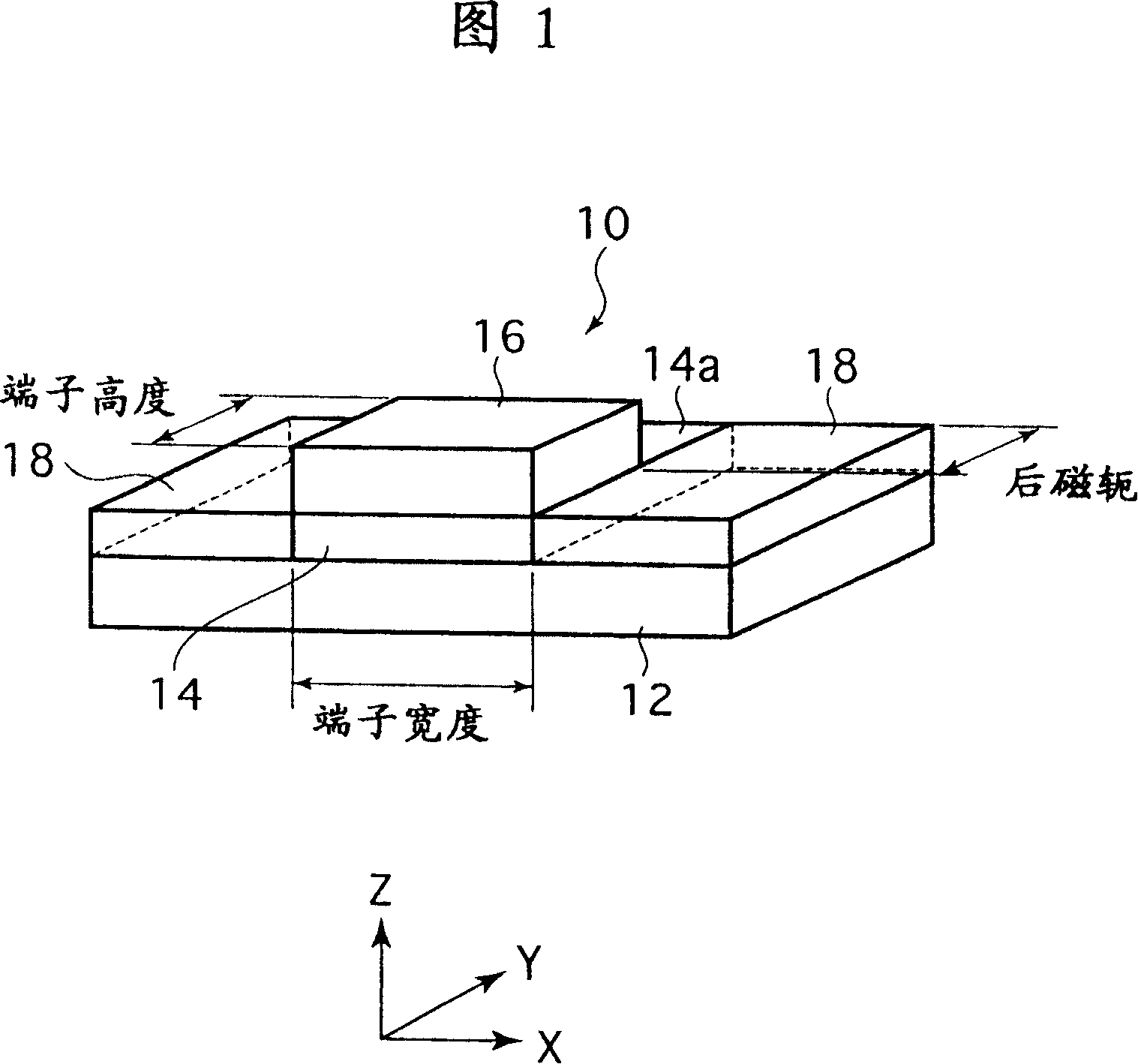

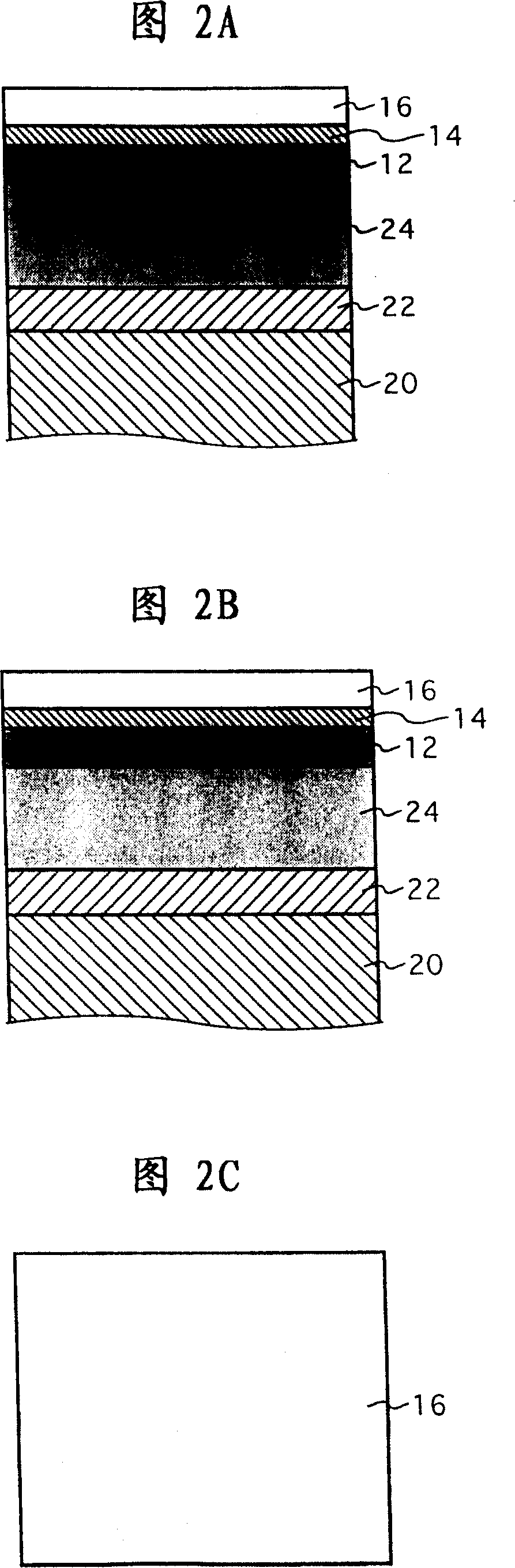

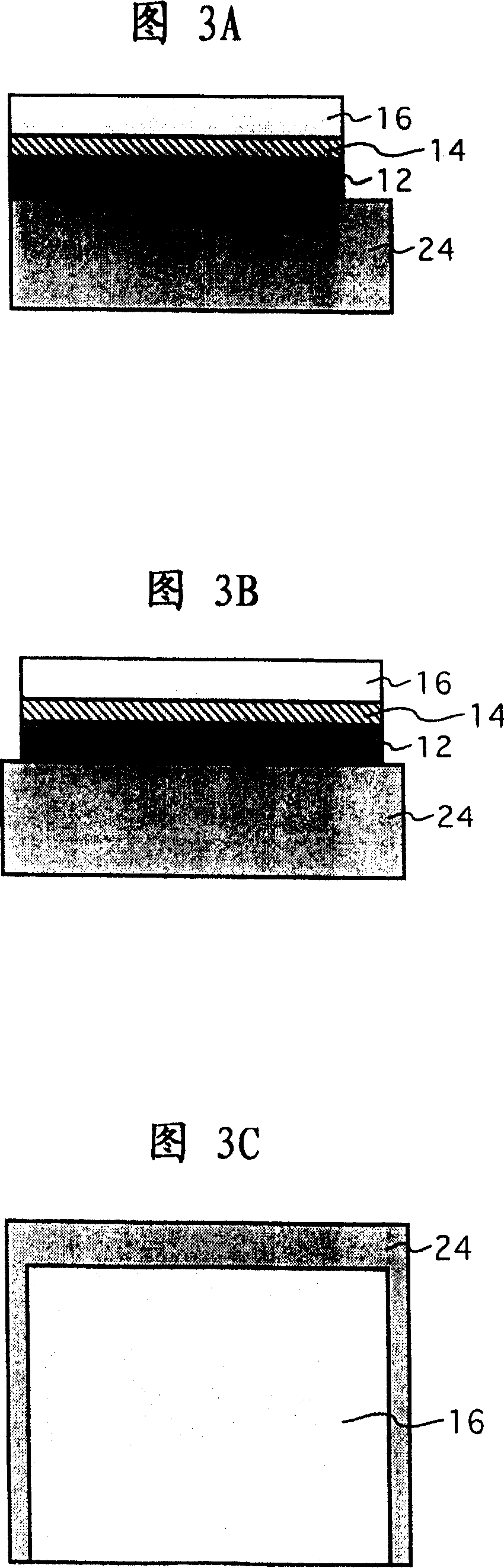

[0051] Some preferred embodiments of the present invention are described below with reference to the accompanying drawings. In the following description of the preferred embodiment, substantially the same parts are denoted by the same reference numerals. Referring to FIG. 1, there is shown a perspective view of a magnetoresistive head 10 according to a first preferred embodiment of the present invention. In Fig. 1, the upper and lower magnetic shields are not shown. Figure 12 shows the lower electrode terminal formed of copper or a combination of copper and gold. The lower electrode terminal 12 has a first width in the X direction shown in FIG. 1 and a first height in the Y direction described in FIG. 1 .

[0052] A magnetoresistive film (MR film) 14 is formed on the lower electrode terminal 12 . The MR thin film 14 has a second width smaller than the first width in the X direction and has a height equal to the first height in the Y direction. A pair of magnetic domain con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com