Comprehensive utilization method of by-product for poycrystalline silicon production process

A production process and by-product technology, applied in the field of comprehensive utilization of by-products in the polysilicon production process, can solve the problems of limited dosage, incomplete utilization, and little research on the comprehensive utilization of polysilicon industry by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

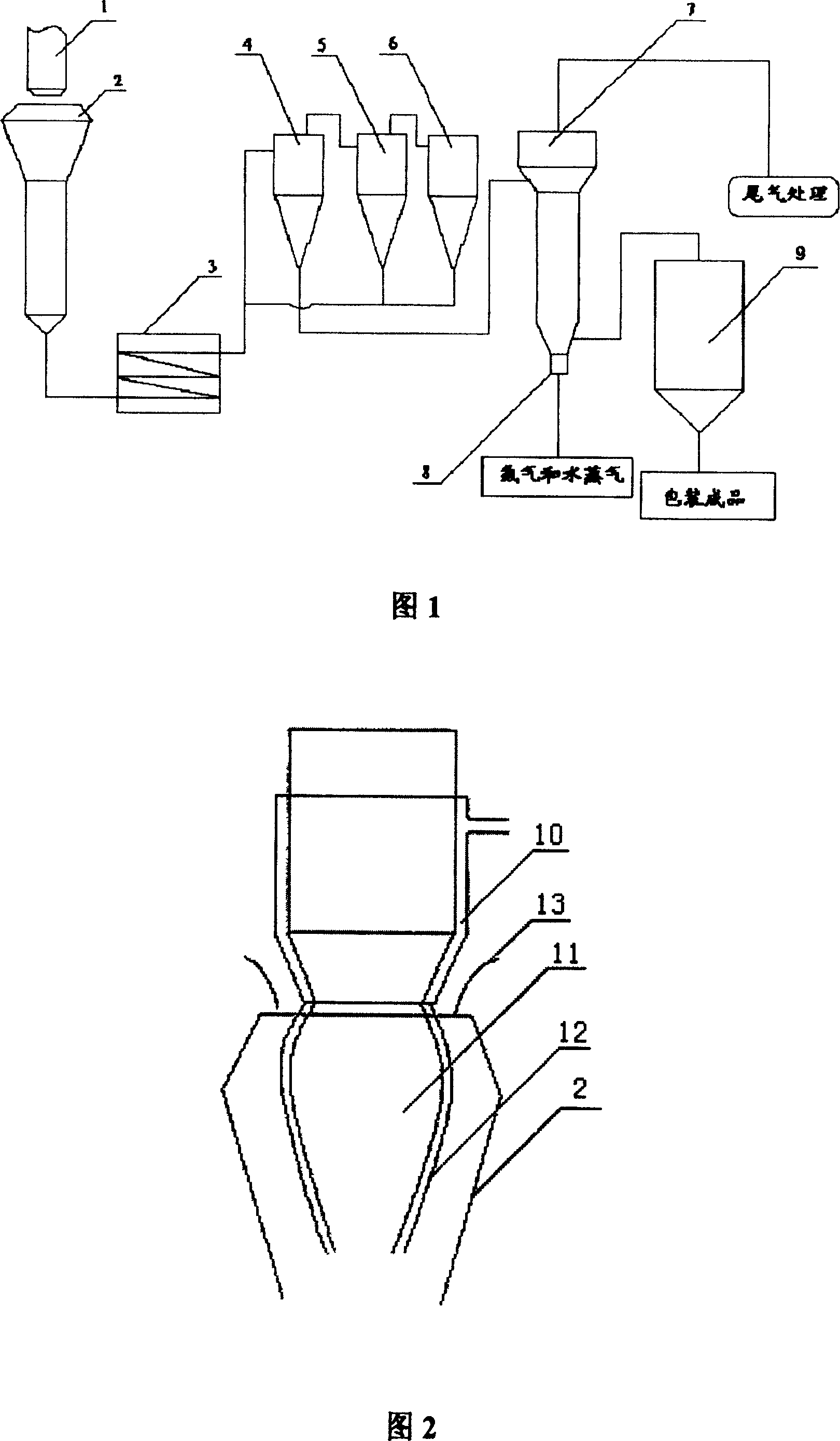

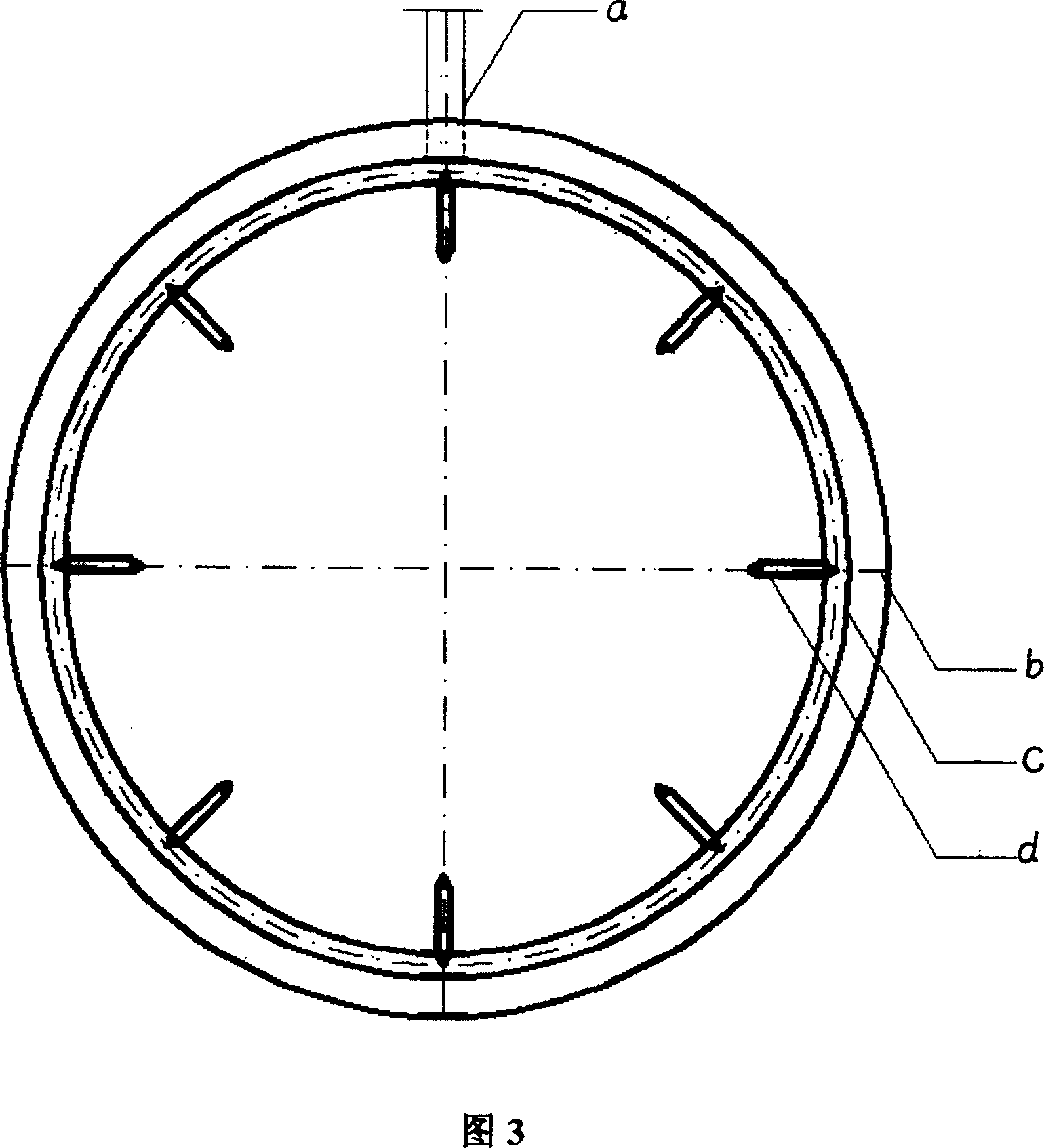

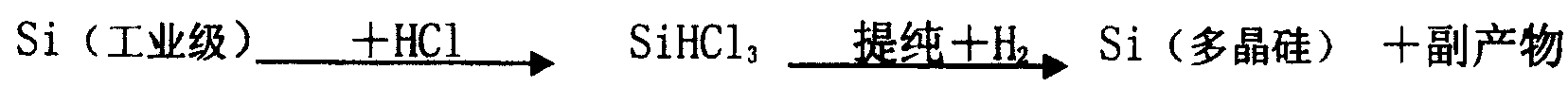

Method used

Image

Examples

Embodiment 1

[0039] Polysilicon by-products are vaporized at 100-120°C, in molar ratio n 多晶硅副产物 / n 氢气 / n 空气 The mixing ratio of =1 / 2.2 / 4.5 is fully mixed with hydrogen and air at a temperature of 120-140°C after preheating, and then continuously and stably transported to the nozzle for high-temperature hydrolysis reaction. Control the temperature in the deacidification furnace to 540°C, and the temperature of the deacidification medium to 160°C. The quality index of the prepared silica is:

[0040] Silica content (%) 99.90

[0041] Primary particle average size (nm) 18

[0042] Specific surface area (m 2 / g) 160

[0043] pH value (4% suspension) 4.18

Embodiment 2

[0045] Polysilicon by-products are vaporized at 100-120°C, in molar ratio n 多晶硅副产物 / n 氢气 / n 空气 =1 / 2.4 / 5 The mixing ratio is fully mixed with hydrogen and air at a temperature of 120-140°C after preheating, and then continuously and stably delivered to the nozzle for high-temperature hydrolysis reaction. Other processing parameters are identical with embodiment 1, the silicon dioxide quality index of making:

[0046] Silica content (%) 99.86

[0047] Primary particle average particle size (nm) 14

[0048] Specific surface area (m 2 / g) 195

[0049] pH value (4% suspension) 4.02

Embodiment 3

[0051] The by-product of silane coupling agent is vaporized at 100-120°C, in molar ratio n 多晶硅副产物 / n 氢气 / n 空气 The mixing ratio of =1 / 2.4 / 5.2 is fully mixed with hydrogen and air at a temperature of 120-140°C after preheating, and then continuously and stably transported to the nozzle for high-temperature hydrolysis reaction. Other processing parameters are identical with embodiment 1, the silicon dioxide quality index of making:

[0052] Silica content (%) 99.83

[0053] Primary particle average particle size (nm) 20

[0054] Specific surface area (m 2 / g) 146

[0055] pH value (4% suspension) 4.10

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com