Liquid-detecting device and liquid container with the same

A technology for detection devices and liquid containers, applied in liquid level indicators for physical variable measurement, printing, etc., can solve problems such as cracks in the piezoelectric film 160

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Next, a liquid detection device and an ink cartridge (liquid container) equipped with the liquid detection device according to an embodiment of the present invention will be described with reference to the drawings.

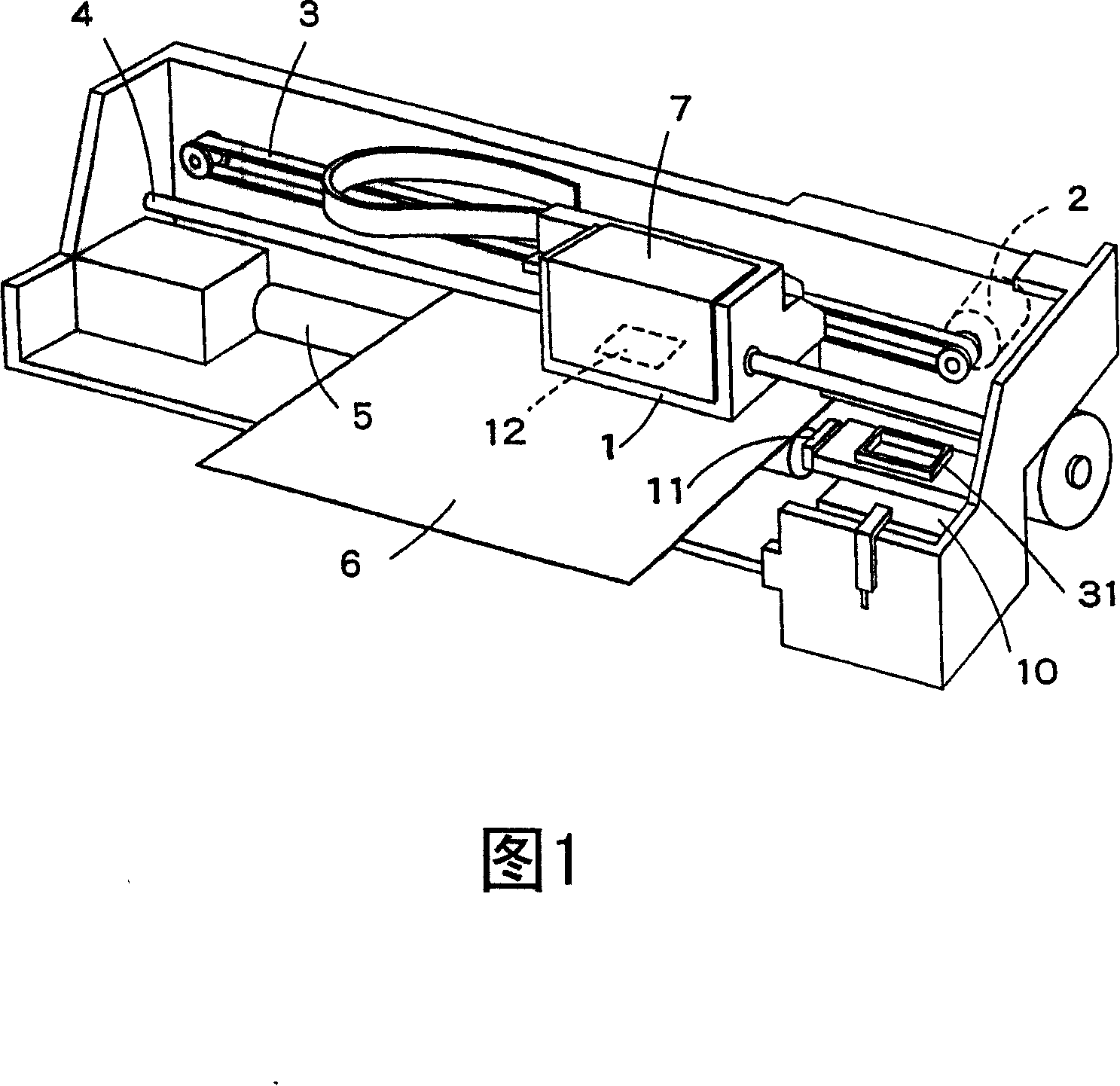

[0089] Fig. 1 shows the schematic structure of the inkjet type recording device (liquid ejection device) using the ink cartridge of this embodiment, and the numeral 1 in Fig. And it is guided by the guide member 4 to reciprocate in the axial direction of the drum 5 .

[0090] An inkjet type recording head 12 is mounted on the side of the carriage 1 facing the recording paper 6 , and an ink cartridge 7 for supplying ink to the recording head 12 is detachably attached to the upper portion thereof.

[0091] In the non-printing area of the recording device, that is, at the home position (right side in the figure), a cover member 31 is arranged. When the recording head loaded on the carriage 1 moves to the home position, the cover member 31 covers the recordi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap