In-plane mono-axial anisotropy test method for magnetic film material

A uniaxial anisotropy, magnetic thin film technology, applied in the direction of material magnetic variables, can solve problems such as inaccuracy, and achieve the effect of simple and accurate anisotropy test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

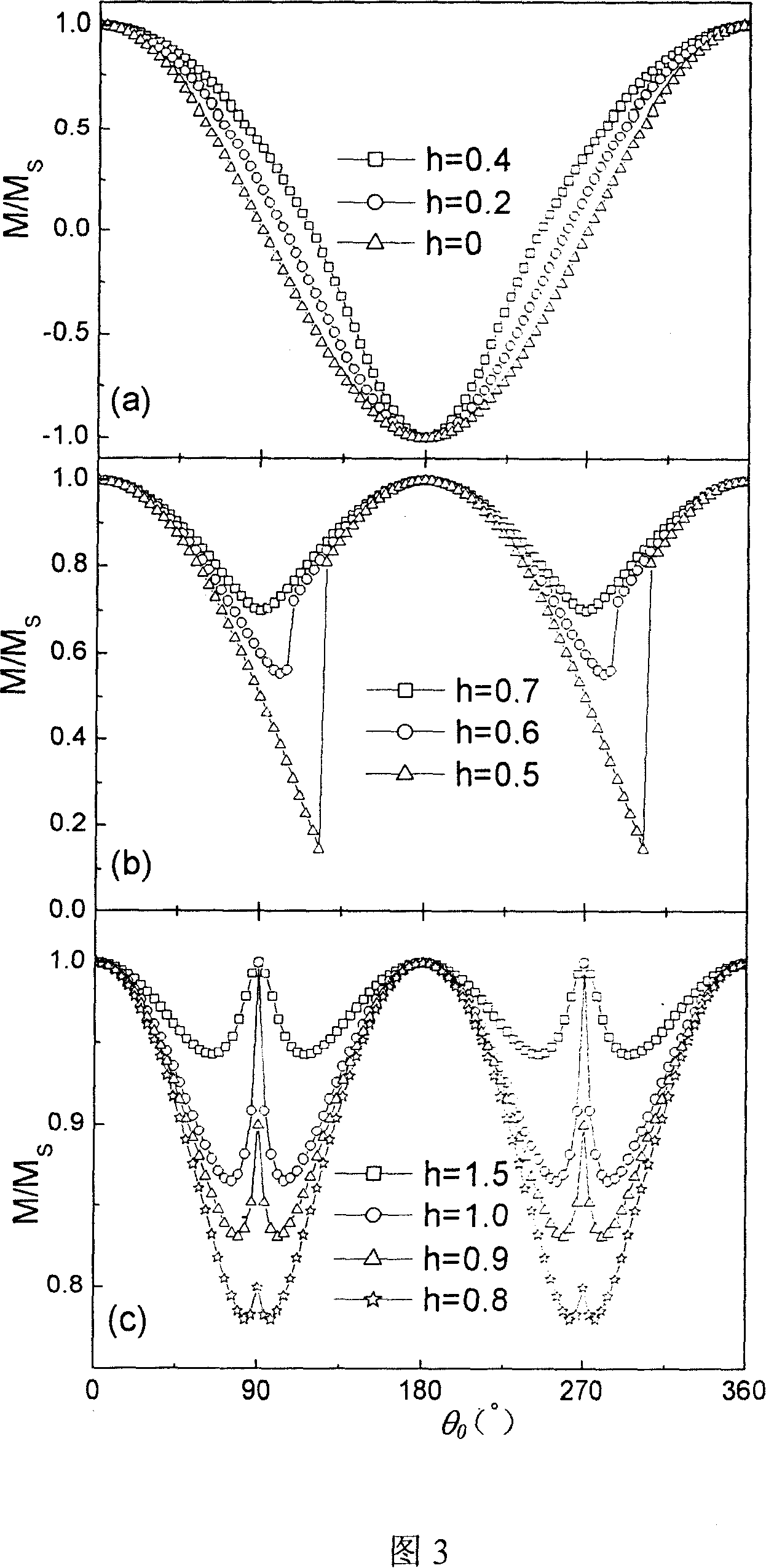

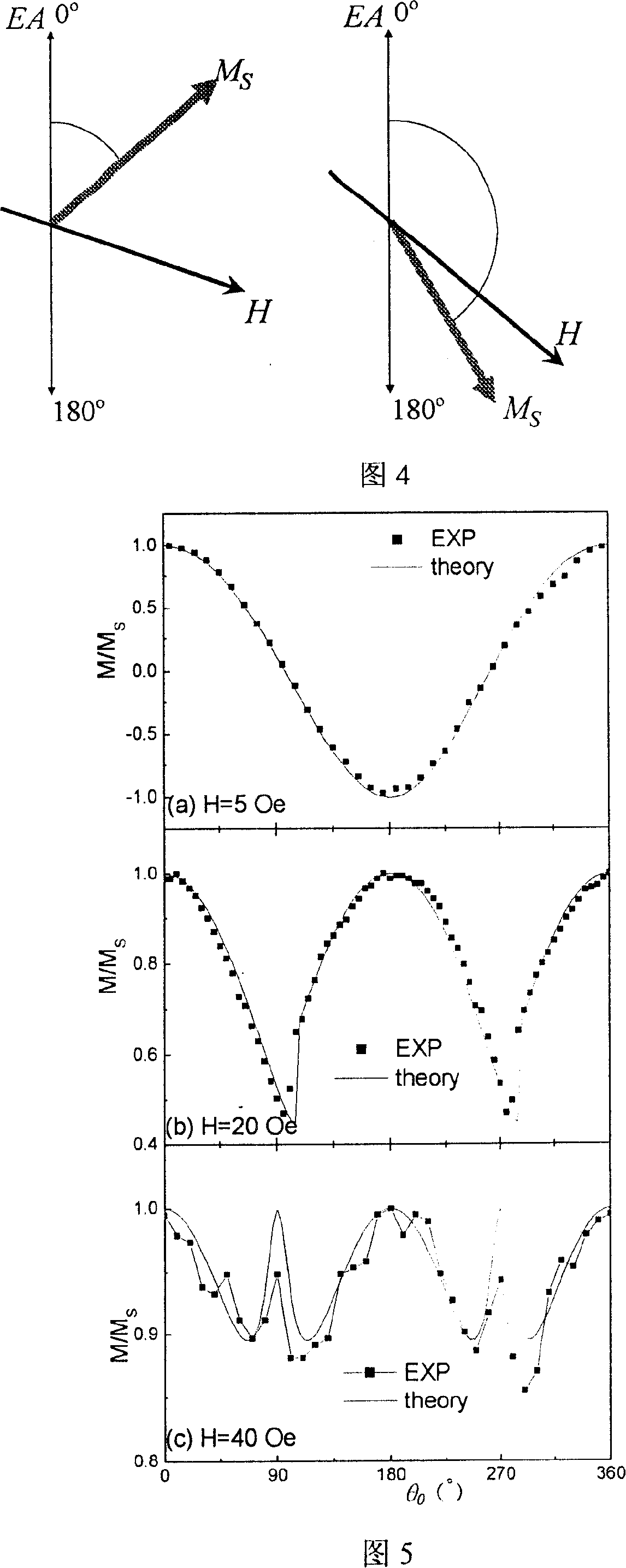

[0011] The present invention is explained below in conjunction with theoretical analysis and actual test:

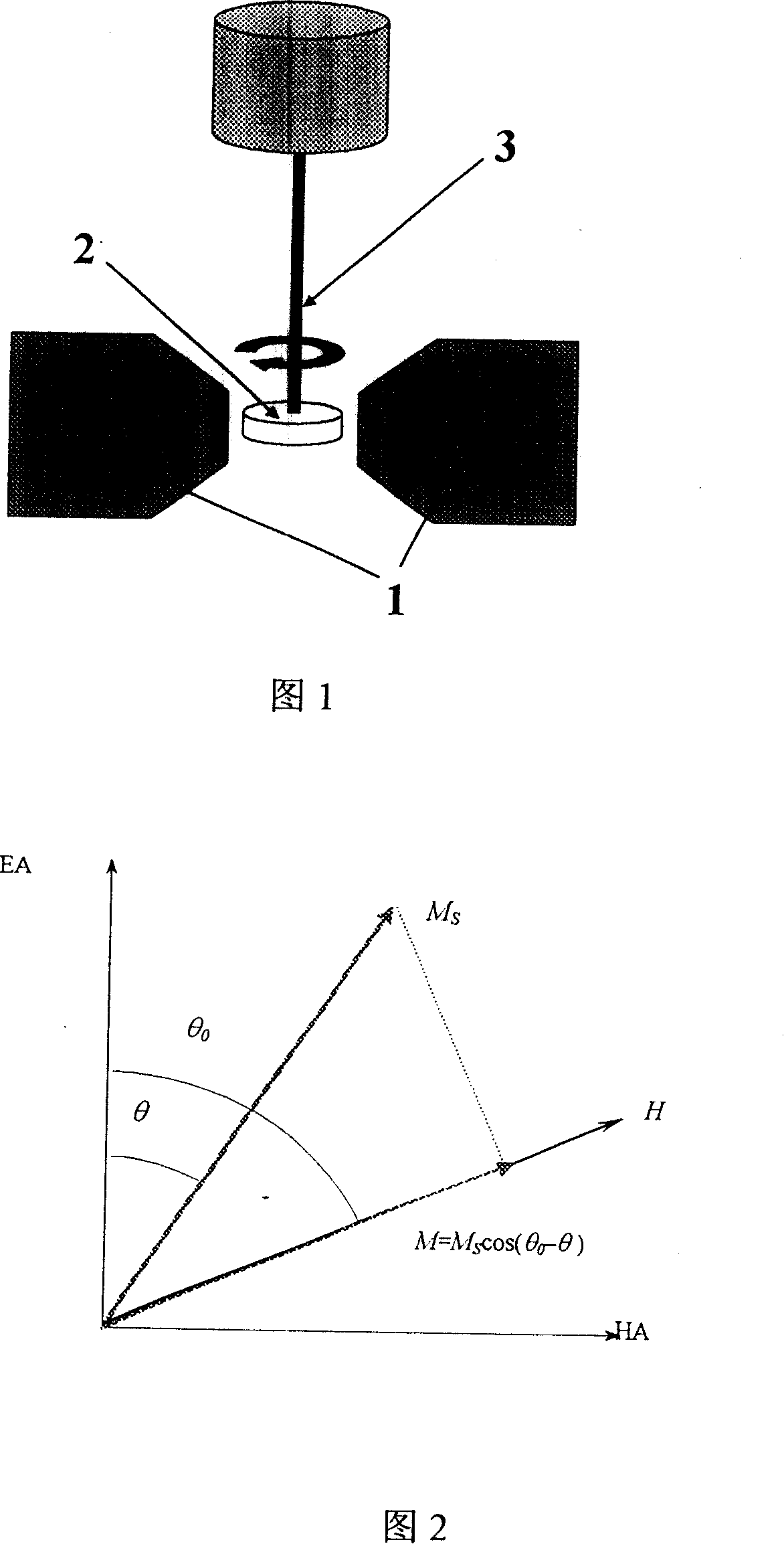

[0012] Fig. 1 is a schematic diagram of the testing device of the present invention, which can be a vibrating sample magnetometer (VSM) experimental device. Among them, 1 is an electromagnet that generates an external magnetic field, 2 is a platform for placing the sample to be tested, and 3 is a shaft that can make the platform 2 rotate. It can be seen from Figure 1 that when the film sample to be tested is placed on the platform 2, the applied magnetic field is parallel to the film, and the film can rotate with the rotation of the platform 2, and its rotation axis is perpendicular to the direction of the external magnetic field.

[0013] When performing the test, the plane of the film to be tested is attached to the platform 2, and at this time the plane of the film material is parallel to the direction of the external magnetic field. When testing, first make the exte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com