Multi-stage transmission

A technology for transmissions and shifting parts, which is applied to vehicle gearboxes, multi-ratio transmissions, transmissions, etc. It can solve the problems of complex structure and guidance of front gear sets, and achieve large torque transmission capacity and large expansion range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

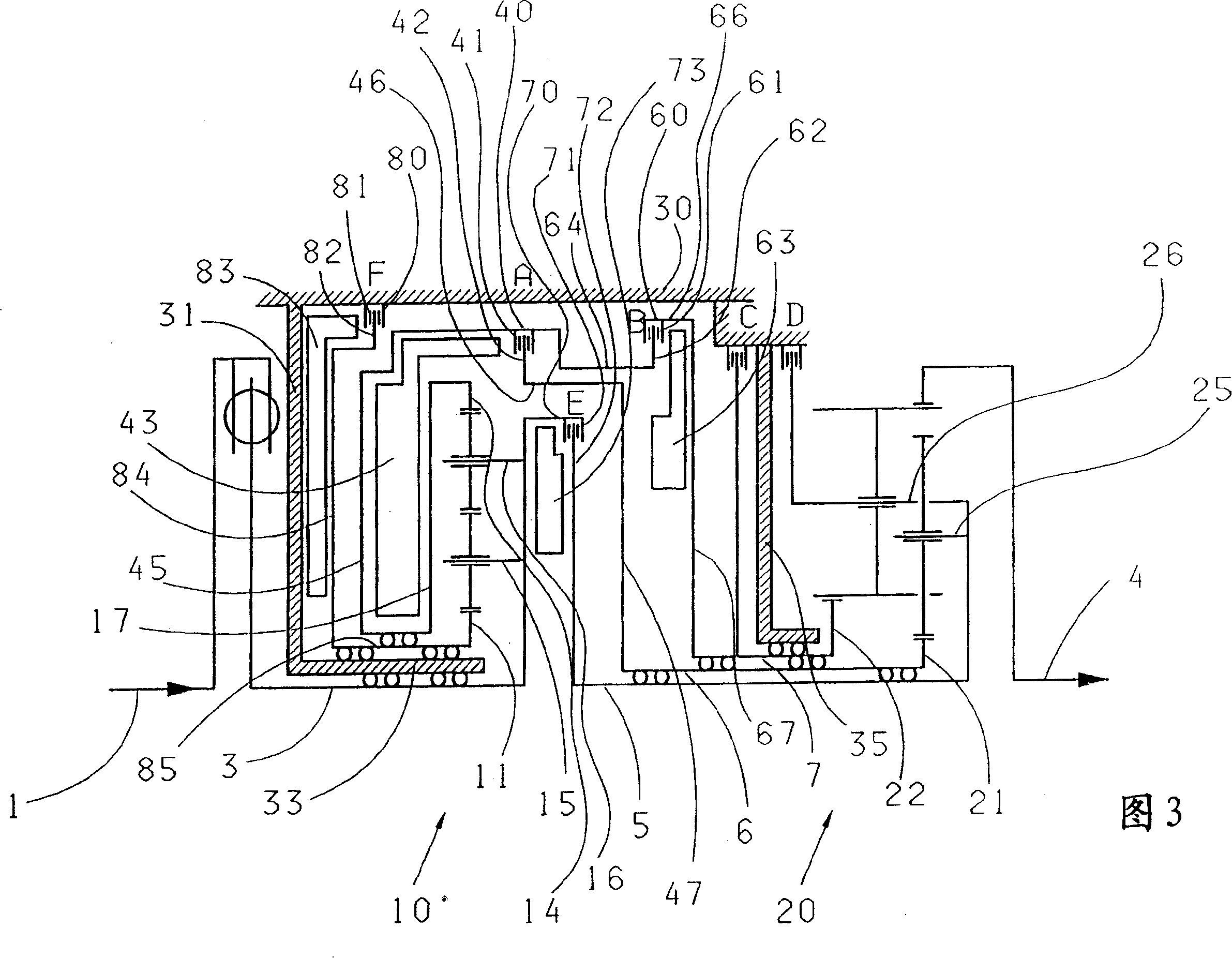

[0036] The same symbols represent similar components throughout the drawings. FIGS. 1 to 33 relate to a first variant of the pre-planetary gear set according to the invention, wherein the pre-planetary gear set is driven via its engaging bridge, its hollow gear can be connected to the main planetary gear set and its sun gear Gears can be fixed. Figures 34 and 35 relate to a second variant of the pre-planetary gear set according to the invention, wherein the pre-planetary gear set is driven by its sun gear, its hollow gear is connectable to the main planetary gear set and its engaging connection Bridges can be fixed.

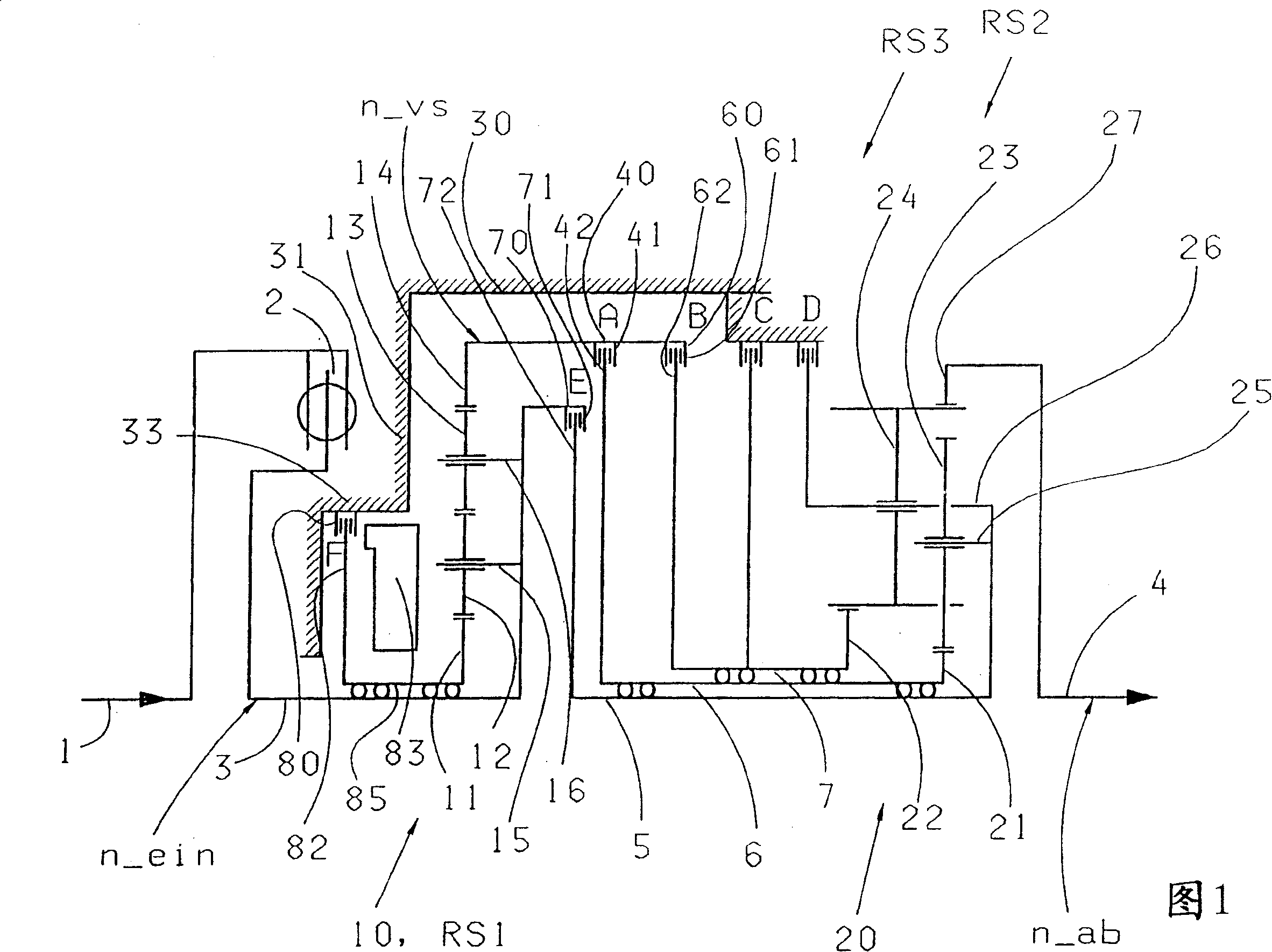

[0037] FIG. 1 shows a transmission system diagram as an example of a first variant of the front planetary gear set according to the present invention. Denoted by 1 is, for example, the engine shaft of an internal combustion engine, via which the multi-speed transmission is driven. For vibration decoupling, a conventional torsional vibration damper 2 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com