Special ceramic double-lining pipe and production method thereof

A special ceramic and production method technology, which is applied in the field of pump components, can solve problems such as sleeve drop, ceramic sleeve dislocation, leakage, etc., and achieve the effects of good temperature resistance, good toughness, and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

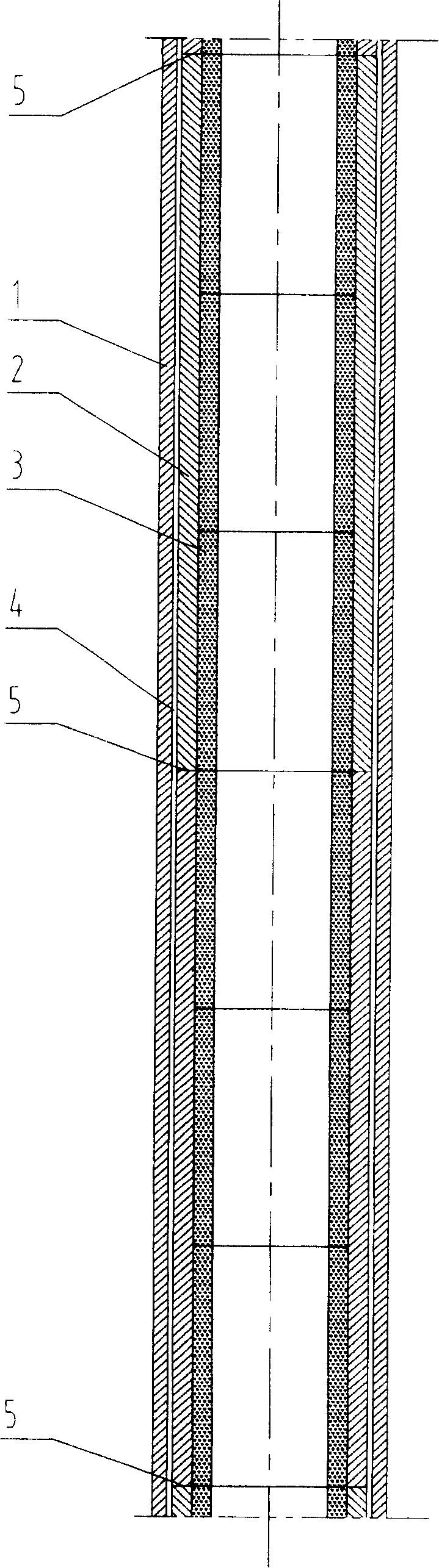

[0014] Embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to make the structural details, features, objectives and advantages of the present invention more clear, but not intended to limit the scope of the present invention.

[0015] The structure of the embodiment of the present invention will now be described in conjunction with the accompanying drawings: as shown in the figure, a special ceramic double-lined pipe consists of an outer pipe 1 and a lined pipe. It is a transition fit between the outer pipe 1 and the liner pipe, keeping a gap 4 of about 2 mm. The liner pipe is thermally sleeved by a steel lining 2 heated to 500°C on three ceramic linings 3 whose length is 1 / 3, and the steel lining 2 is tightly fitted on the ceramic lining 3 In order to give full play to the characteristics of high temperature resistance, corrosion resistance and wear resistance of the ceramic lining 3 formed by special ceramics; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com