Digital level gauge and optical level gauge indoor detection device

A technology of optical level and digital level, which is applied in the direction of measuring devices and instruments, can solve the problems of small space and no indoor verification device, etc., and achieve the effect of simple operation, stable verification value and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

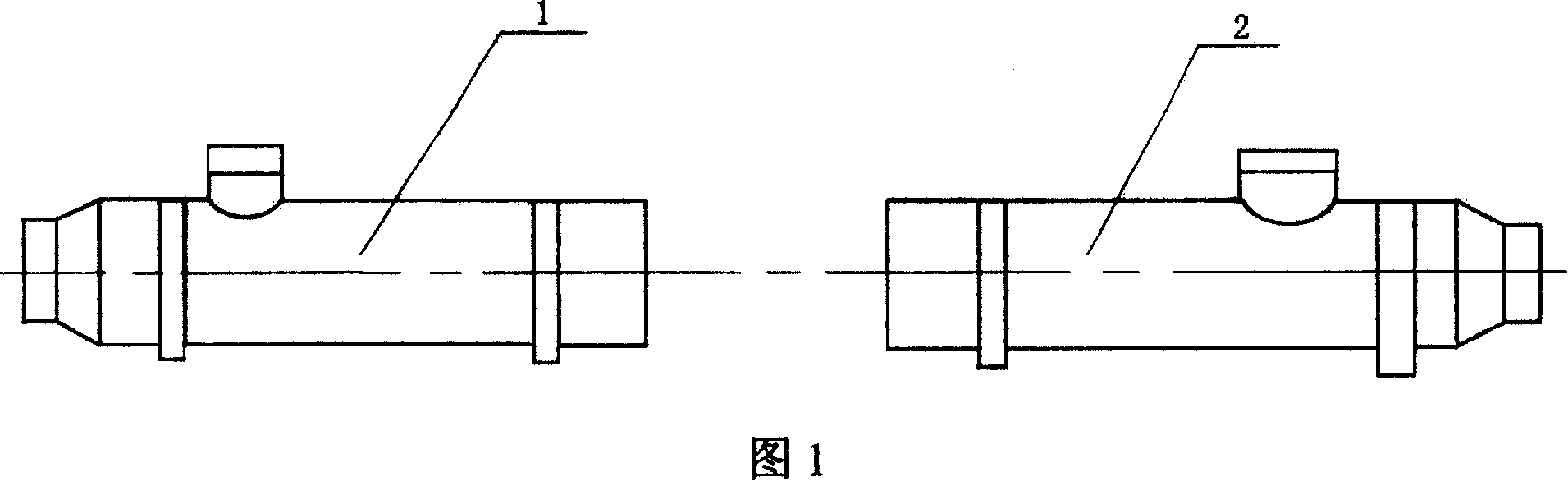

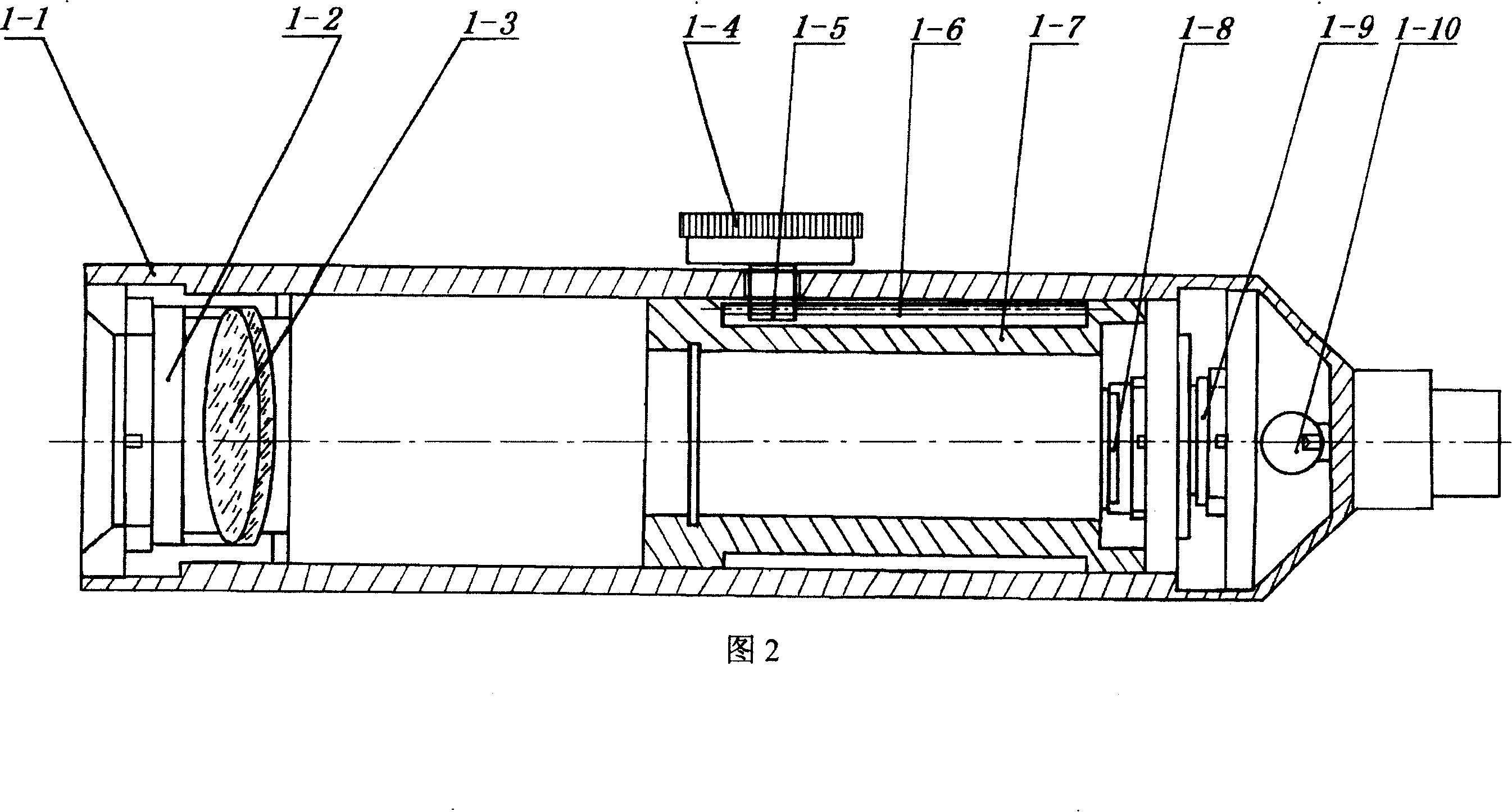

[0018] In Figures 1 and 5, the digital level and the optical level indoor verification device of this embodiment are composed of a front-sight inspection and adjustment collimator 1 and a rear-sight inspection and adjustment collimator 2, and the rear-sight inspection and adjustment collimator 2 is connected to the front The structures of the collimator 1 are identical for inspection and adjustment. When verifying the digital level and the optical level, fix the front-sight inspection and adjustment collimator 1 on the front-sight cement pier 8, the rear-sight inspection and adjustment collimator 2 on the rear-sight cement pier 6, and the digital level 3 or optical level to be tested The level is fixed on the two-dimensional micro-tilt platform 4 on the same axis between the front-view inspection collimator 1 and the rear-view inspection collimator 2, and the two-dimensional micro-tilt platform 5 is installed on the cement pier 7 fixed on the instrument under test. On the lift...

Embodiment 2

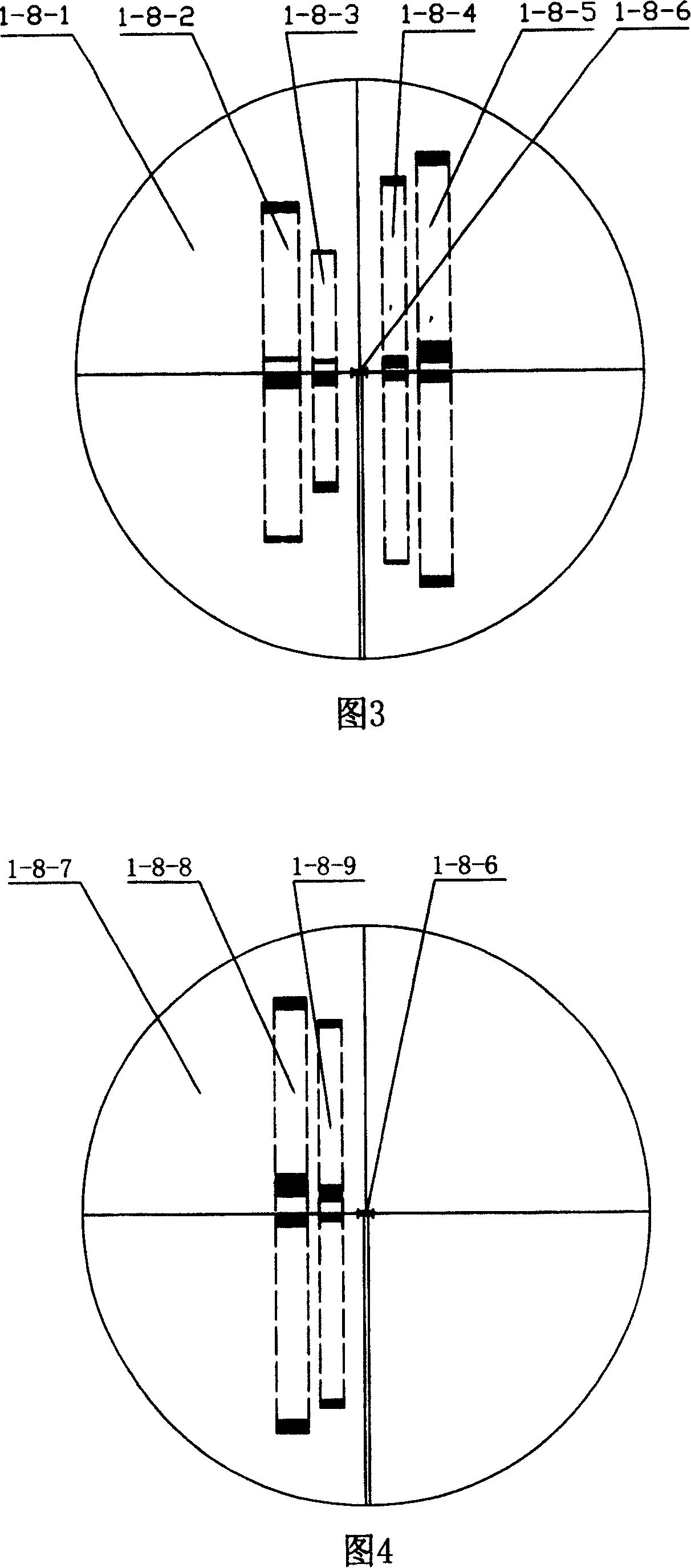

[0023] In this embodiment, the Zeiss short-distance barcode 1-8-2 is to engrave 41 barcodes on a lens 1-8- In the first column on the left of 1, the Zeiss long-distance barcode 1-8-3 is to engrave the 59 barcodes on the Zeiss barcode scale of the Zeiss series digital level with a distance of 424mm from bottom to top by 120 times and engrave it on a lens 1- 8-1, the second column on the left, Leica long-distance barcode 1-8-4 is to engrave 161 barcodes on a lens with a distance of 921mm from the bottom to the top of the barcode on the barcode of the Leica series digital level by 120 times. The third column on the left of -8-1, the Leica close-range barcode 1-8-5 is to reduce the barcode on the barcode scale of the Leica series digital level from bottom to top with a distance of 544mm by 50 times and engrave it on a lens 1-8-1 on the fourth column from the left. Topcon short-distance barcode 1-8-8 is to engrave 141 barcodes on the barcode scale of Topcon series digital levels w...

Embodiment 3

[0025] In this embodiment, the Zeiss short-distance barcode 1-8-2 is to engrave 41 barcodes on a lens 1-8- In the first column on the left of 1, the Zeiss long-distance barcode 1-8-3 is to engrave the 59 barcodes on the Zeiss barcode ruler of the Zeiss series digital level with a distance of 424mm from bottom to top by 200 times and engrave them on a lens 1- 8-1, the second column on the left, Leica long-distance barcode 1-8-4 is to engrave 161 barcodes on a lens with a distance of 921mm from the bottom to the top of the barcode on the barcode scale of the Leica series digital level by 200 times. The third column on the left of -8-1, the Leica close-range barcode 1-8-5 is to engrave 84 barcodes on a lens with a distance of 544mm from the bottom to the top of the barcode on the barcode of the Leica series digital level by 100 times. 1-8-1 on the fourth column from the left. Topcon short-distance barcode 1-8-8 reduces the barcode on the barcode scale of Topcon series digital le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com