Device for harnessing bittern burst of brine well by blasting

A salt well and central pipe technology, which is applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of limited axial direction, failure of control, inability to maintain long-lasting blocking and channeling, and improve compression resistance. , Reliable cavity formation, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

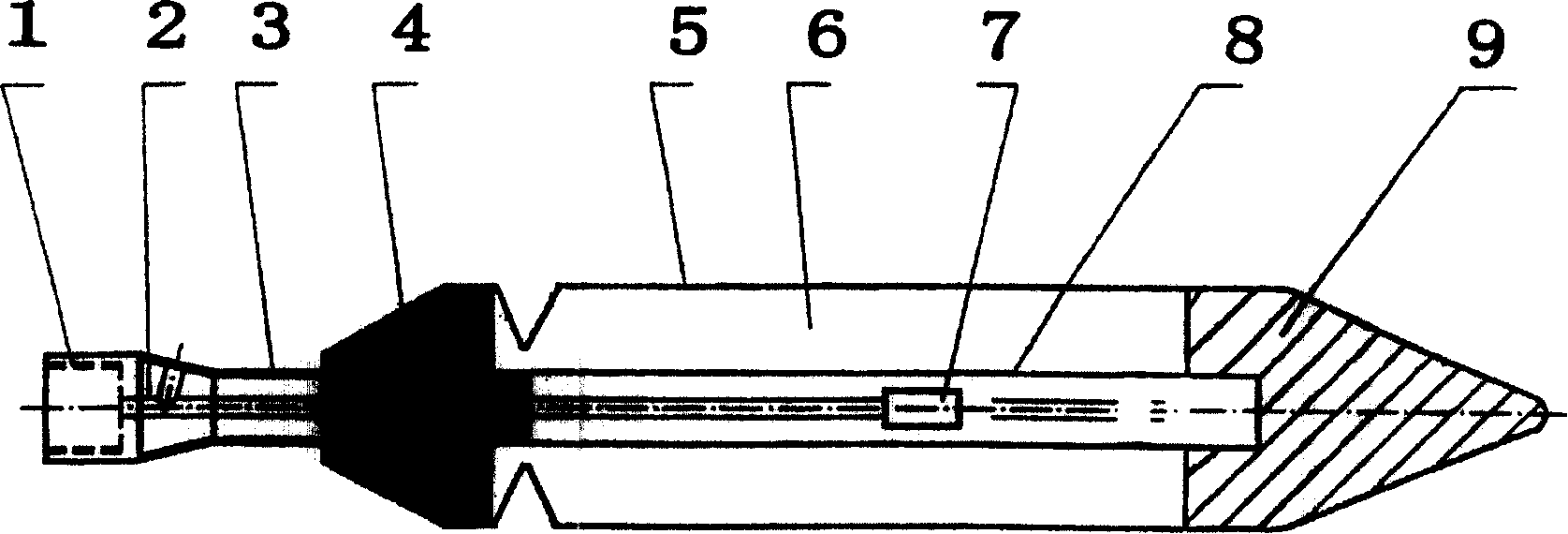

[0008] Specific embodiment: as accompanying drawing: device is made up of connecting nut 1, detonator lead wire 2, unloading tube 3, upper guide cone 4, shell 5, explosive 6, detonator bundle 7, central tube 8, explosive packer 9. The casing 5 is a metal cylinder with a ring-shaped V-shaped groove on the upper part. One end surface of the casing 5 is connected to the explosive packer 9 whose upper part is conical and the lower part is cylindrical, and the other end surface is connected to the upper guide cone 4. On one side of the upper guide cone 4, there is a force relief pipe 3 with a connecting nut 1 at one end, and on the other side, there is a center pipe 8 made of metal material extending into the explosion packer 9 in the shell, and the center The tube 8 communicates with the unloading tube 3, and the central tube 8 is provided with a detonator bundle 7 and a detonator lead wire 2, and the part between the central tube 8 and the shell 5 and the part of the central tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com