Alloy plastic composite cable bridge and preparation method thereof

A cable bridge, alloy plastic technology, applied in the direction of electrical components, polyether coatings, coatings, etc., can solve the problems of accelerated corrosion rate, accelerated corrosion rate, electrolytic corrosion, etc., achieve good chemical resistance, avoid corrosion problems, reduce The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

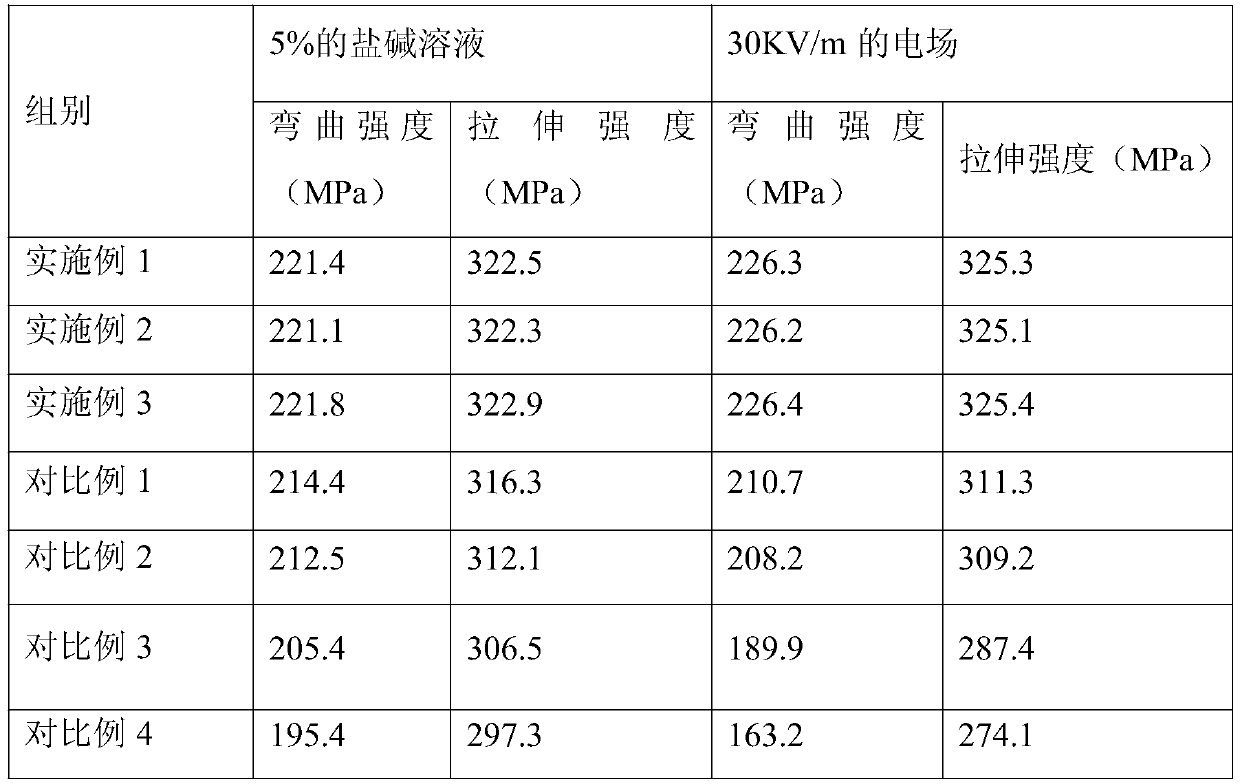

Examples

Embodiment 1

[0030] An alloy plastic composite cable tray of this embodiment includes the following raw materials in parts by weight:

[0031] 45 parts of PVC, 10 parts of ABS, 3 parts of corrosion-resistant dielectric agent, 5 parts of calcium borosilicate glass powder, 3 parts of modified pearl mica powder, 20 parts of composite spraying powder.

[0032] The preparation method of the corrosion-resistant dielectric agent of this embodiment is: add the corrosion-resistant liquid to the high-viscosity silicone oil, then stir at a speed of 500r / min for 20-min, then add silica particles and TiC powder, and then Reduce the rotational speed to 150r / min and stir at a low speed for 1 hour, and the stirring is completed to obtain a corrosion-resistant dielectric agent.

[0033] The preparation method of the anti-corrosion solution in this embodiment is to add lauryl glucoside into phenoxyethanol, then add polydimethylsiloxane, stir while adding, the stirring speed is 100r / min, and the addition is ...

Embodiment 2

[0046] An alloy plastic composite cable tray of this embodiment includes the following raw materials in parts by weight:

[0047] 55 parts of PVC, 20 parts of ABS, 10 parts of corrosion-resistant dielectric agent, 15 parts of calcium borosilicate glass powder, 7 parts of modified pearl mica powder, and 30 parts of composite spraying powder.

[0048] The preparation method of the corrosion-resistant dielectric agent in this embodiment is: add the corrosion-resistant liquid to the high-viscosity silicone oil, then stir at a speed of 600r / min for 30min, then add silica particles and TiC powder, and then increase the speed to Decrease to 250r / min and carry out low-speed stirring for 2 hours, and the stirring is completed to obtain a corrosion-resistant dielectric agent.

[0049] The preparation method of the anti-corrosion solution of this embodiment is to add lauryl glucoside into phenoxyethanol, then add polydimethylsiloxane, stir while adding, the stirring speed is 100r / min, an...

Embodiment 3

[0062] An alloy plastic composite cable tray of this embodiment includes the following raw materials in parts by weight:

[0063] 50 parts of PVC, 15 parts of ABS, 7 parts of corrosion-resistant dielectric agent, 10 parts of calcium borosilicate glass powder, 5 parts of modified pearl mica powder, and 25 parts of composite spraying powder.

[0064] The preparation method of the corrosion-resistant dielectric agent in this embodiment is: add the corrosion-resistant liquid to the high-viscosity silicone oil, then stir at a speed of 550r / min for 25min, then add silica particles and TiC powder, and then increase the speed Decrease to 200r / min and carry out low-speed stirring for 1.5h. After the stirring is completed, a corrosion-resistant dielectric agent is obtained.

[0065] The preparation method of the anti-corrosion solution of this embodiment is to add lauryl glucoside into phenoxyethanol, then add polydimethylsiloxane, stir while adding, the stirring speed is 100r / min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com