Bituminous mixture for heavy-load transportation road surface and preparation technology of bituminous mixture

A technology of asphalt mixture and processing technology, which is applied in the field of asphalt preparation, can solve problems such as reducing the wear resistance of asphalt mixture, affecting road traffic, and improving accidents, so as to improve compatibility, service life, and mechanical properties and the effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

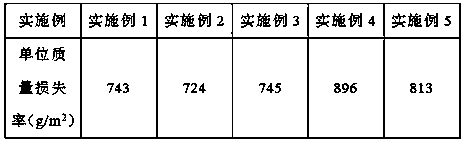

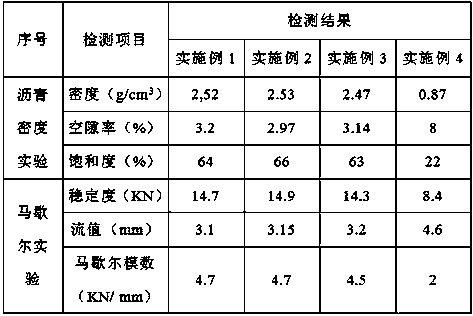

Embodiment 1

[0049] First, weigh aggregate, asphalt, stabilizer, compatibilizer, filler, polytetrafluoroethylene fiber, nano-silica in proportion, and set aside; then take nano-silica and polytetrafluoroethylene fiber, crush them, and put them into the mixer Stir, heat to 315°C after stirring evenly, and keep warm for 3h; reheat, heat up to 370°C, keep warm for 2h; hot press and sinter under 255MPa pressure to prepare material A; then weigh calcium sulfate whisker, silicone rubber in proportion and ethyl orthosilicate, put the silicone rubber into a stirring tank, add calcium sulfate whiskers, and stir at room temperature for 10 minutes; then add ethyl orthosilicate, stir evenly, degas under vacuum at room temperature, and place it for 24 hours to obtain an anti-wear agent; Then heat the asphalt to 180°C, turn on the mixing and shearing machine, then add the prepared material A, the prepared wear-resistant agent, aggregate and filler, and shear and stir for 20 minutes; continue to add stabi...

Embodiment 2

[0053] First, weigh aggregate, asphalt, stabilizer, compatibilizer, filler, polytetrafluoroethylene fiber, nano-silica in proportion, and set aside; then take nano-silica and polytetrafluoroethylene fiber, crush them, and put them into the mixer Stir, heat to 325°C after stirring evenly, keep warm for 4h; reheat, heat up to 375°C, keep warm for 3h; hot press and sinter under 260MPa pressure to prepare material A; then weigh calcium sulfate whisker, silicone rubber in proportion and ethyl orthosilicate, put silicone rubber into a stirring tank, add calcium sulfate whiskers, and stir at room temperature for 20 minutes; then add ethyl orthosilicate, stir evenly, degas under vacuum at room temperature, and place for 24 hours to obtain an anti-wear agent; Then heat the asphalt to 190°C, turn on the mixing and shearing machine, then add the prepared material A, the prepared wear-resistant agent, aggregate and filler, and shear and stir for 25 minutes; continue to add stabilizers, con...

Embodiment 3

[0057] First, weigh aggregate, asphalt, stabilizer, compatibilizer, filler, polytetrafluoroethylene fiber, nano-silica in proportion, and set aside; then take nano-silica and polytetrafluoroethylene fiber, crush them, and put them into the mixer Stir, heat up to 330°C after stirring evenly, and keep warm for 5h; reheat, heat up to 380°C, keep warm for 4h; hot press and sinter under 265MPa pressure to prepare material A; then weigh calcium sulfate whiskers and silicone rubber in proportion and ethyl orthosilicate, put silicone rubber into a stirring tank, add calcium sulfate whiskers, and stir at room temperature for 25 minutes; then add ethyl orthosilicate, stir evenly, vacuum degas at room temperature, and place for 24 hours to obtain an anti-wear agent; Then heat the asphalt to 195°C, turn on the stirring and shearing machine, then add the prepared material A, the prepared wear-resistant agent, aggregate and filler, and shear and stir for 30 minutes; continue to add stabilize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com