Evaporation residue solidification process based on landfill leachate full-quantitative treatment

A technology for landfill leachate and evaporative residue, which is applied in the treatment of polluted groundwater/leachate, water/sewage treatment, sustainable waste treatment, etc., can solve the problems of affecting the solidification effect, increasing the operating cost, and increasing the amount of lime, etc. Achieve the effect of improving the curing effect and heavy metal stabilization effect, ensuring the curing effect, and improving the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

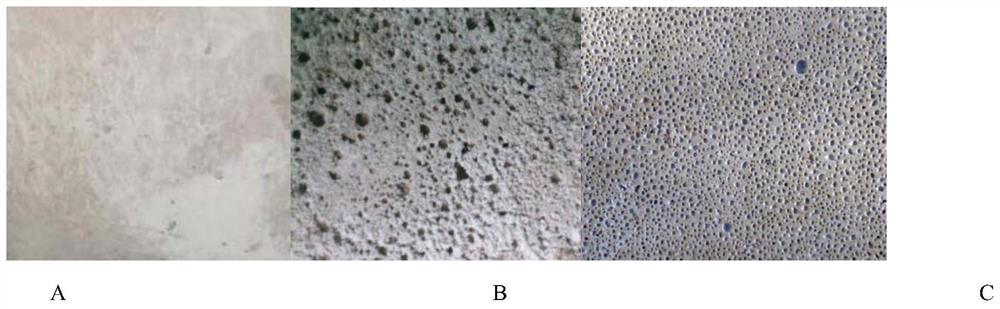

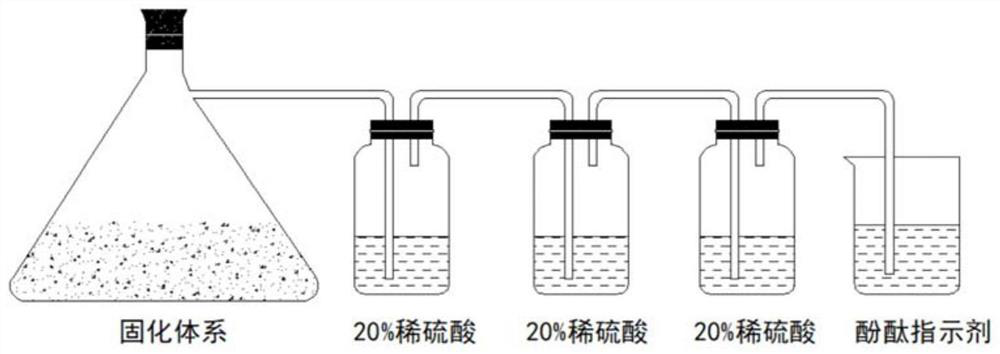

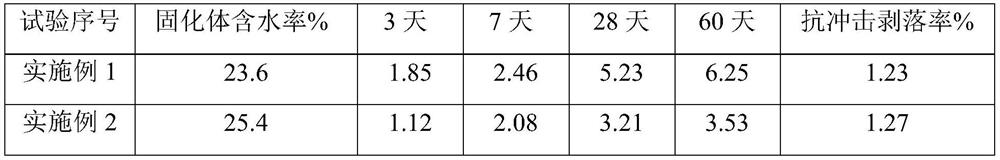

[0057] Take 100kg of landfill leachate evaporation residue with a water content of 85%, add 200kg of +200 mesh content of 25.3% water-quenched residue, 0.3Kg of stabilizer acetate, stir for 2 minutes, add 60kg of PC425 Portland cement and polycarboxylic acid 0.1kg, continue to stir for 3 minutes, put it into a molding mold, and cure it under natural conditions for 3 days, 7 days, 28 days, and 60 days.

Embodiment 2

[0060] Take 100kg of landfill leachate evaporation residue with a moisture content of 80%, add 180kg of steel slag with a +200 mesh content of 35.6%, 0.25Kg of stabilizer oxalate, stir for 2 minutes, add 35kg of PC425 portland cement and rhamnolipid 0.12 kg, continue to stir for 5 minutes, put into the forming mold, and cure under natural conditions for 3 days, 7 days, 28 days, and 60 days.

Embodiment 3

[0063] Take 100kg of landfill leachate evaporation residue with a water content of 75%, add 130kg of +200 mesh content of 31.3% slag, 0.35Kg of stabilizer sulfite, stir for 3 minutes, add 40kg of PC425 Portland cement and 0.15kg of metasilicate , continue to stir for 5 minutes, put it into the forming mold, and maintain it under natural conditions for 3 days, 7 days, 28 days, and 60 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com