High temperature resistance water swelling body with high degree of mineralization, preparation method and application thereof

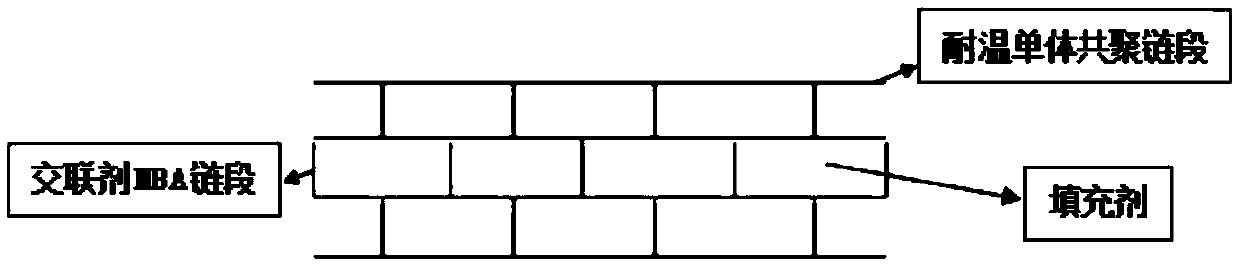

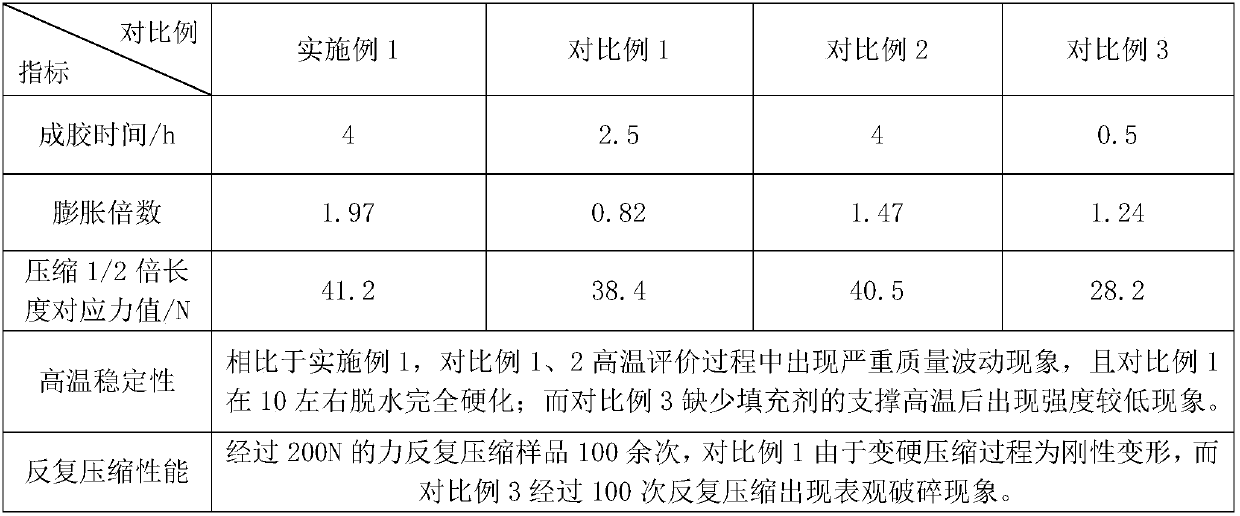

A technology with high salinity and high temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of dehydration and hardening, and cannot meet the requirements of plugging strength and stability, so as to increase water absorption capacity, Good elasticity, good strength and elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

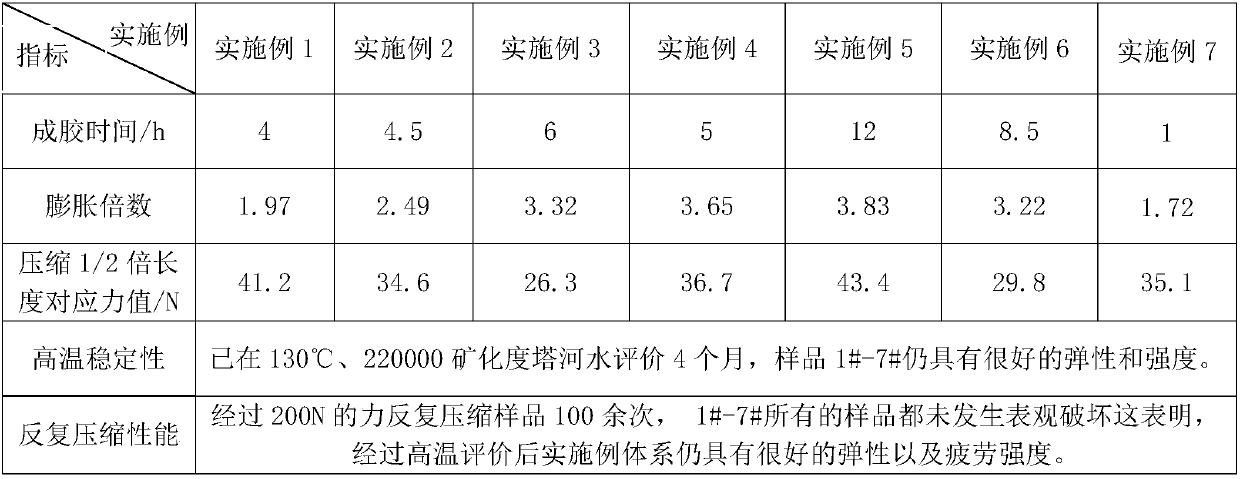

[0034] In 37.5g clay mother liquor, add 30g monomer (molar ratio N,N-dimethylacrylamide and sodium p-vinylbenzenesulfonate=4:6), 5.31g MBA solution, 4g azobisisobutylamidine hydrochloride After salt, 6g sodium persulfate solution, stir evenly, then add salinity to the mixed solution and be the sodium chloride aqueous solution of 1000mg / L to make up 100g of solution. The above-mentioned obtained solution is mixed uniformly, placed in a jar, placed in a water bath at 50° C. and heated over water to obtain the water-swollen body of the present invention.

[0035] The gelling time of the water-swellable body obtained in this example is 4 hours, placed at 130°C, and the degree of salinity is 22×10 4 mg / L Tahe water aged for 117 days without carbonization, and still has good strength and elasticity, and the final water absorption multiple of about 117 days is 1.97.

Embodiment 2

[0037] In 37.5g clay mother liquor, add 30g monomer (molar ratio N,N-dimethylacrylamide and sodium p-vinylbenzenesulfonate=5:5), 5.31g MBA solution, 4g azobisisobutylamidine hydrochloride After salt, 6g sodium persulfate solution, stir evenly, then add salinity to the mixed solution and be the sodium chloride aqueous solution of 1000mg / L to make up 100g of solution. The above-mentioned obtained solution is mixed uniformly, placed in a jar, placed in a water bath at 50° C. and heated over water to obtain the water-swollen body of the present invention.

[0038] The gelling time of the water-swellable body obtained in this example is 4.5h, placed at 130°C, and the degree of salinity is 22×10 4 mg / L Tahe water aged for 117 days without carbonization, and still has good strength and elasticity, and the final water absorption multiple of about 117 days is 2.49.

Embodiment 3

[0040] In 37.5g clay mother liquor, add 30g monomer (molar ratio N,N-dimethylacrylamide and sodium p-vinylbenzenesulfonate=6:4), 5.31g MBA solution, 4g azobisisobutylamidine hydrochloride After saline solution, 6g sodium persulfate solution, stir evenly, then add the sodium chloride aqueous solution that salinity is 1000mg / L to the mixed solution and make up 100g of solution. The above-mentioned obtained solution is mixed uniformly, placed in a jar, placed in a water bath at 50° C. and heated over water to obtain the water-swollen body of the present invention.

[0041] The gelling time of the water-swelling body obtained in this example is 6 hours, placed at 130° C., and the degree of salinity is 22×10 4 mg / L Tahe water aged for 117 days without carbonization, and still has good strength and elasticity, and the final water absorption multiple of about 117 days is 3.32.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com