Explosion-proof explosion-release full-automatic bag-type filtering device for pulverized bituminous coal

A bag filter device, fully automatic technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as high resistance of equipment, spontaneous combustion accidents of the box, damage to filter bags, etc., and achieve clean gas emission The effect of high effect, low equipment resistance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

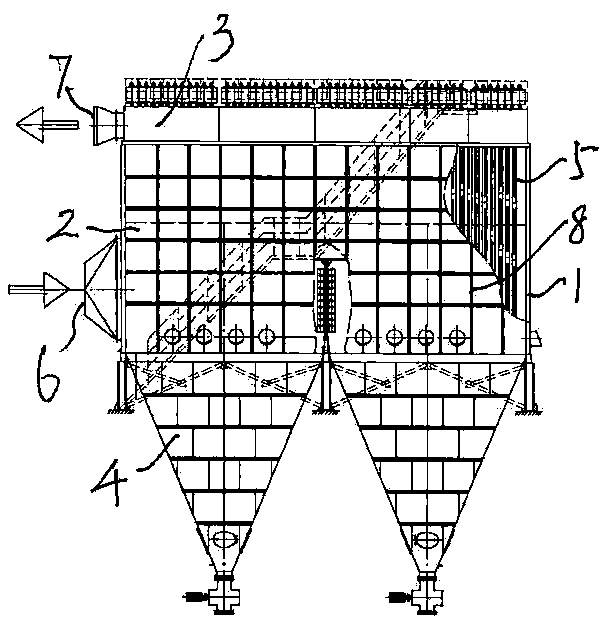

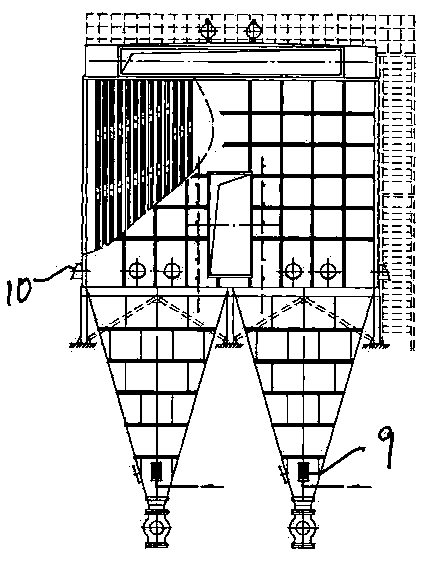

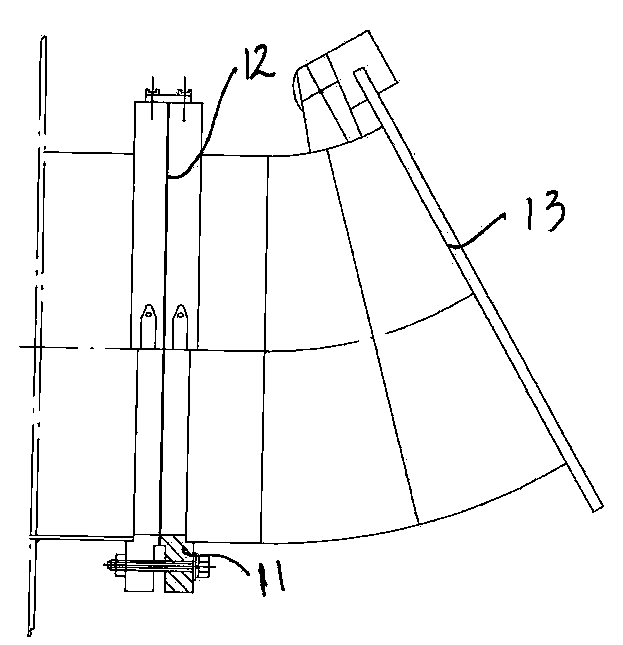

[0021] An explosion-proof and explosion-relief full-automatic bag-type filtering device for bituminous coal powder, comprising a box body 1, a filter room 2 in the middle of the box body, a clean air room 3 in the upper part of the box body, an ash bucket 4 in the lower part of the box body, and a filter chamber in the filter room. Bag 5, the upper opening of the filter bag communicates with the clean air chamber, the clean air chamber is equipped with a clean air duct for blowing clean air to the upper opening of the filter bag, the filter chamber of the box is provided with an air inlet 6, and the clean air chamber of the box There is an air outlet 7 at the position, and the air inlet is connected with the flue gas duct in the filter area. A porous baffle is set in the air duct.

[0022] The lower part of the flue baffle also needs to be provided with a figure-eight deflector to protect the filter bag near the baffle area from being worn.

[0023] The four corners inside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com