Control method and device for crystal ball grinding / polishing machine

A control method and crystal ball technology, applied to grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, and parts of grinding machine tools, etc., can solve the problems of lower production costs, poor precision, and high production costs, and achieve The effect of reducing production costs, improving precision, and improving yield and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

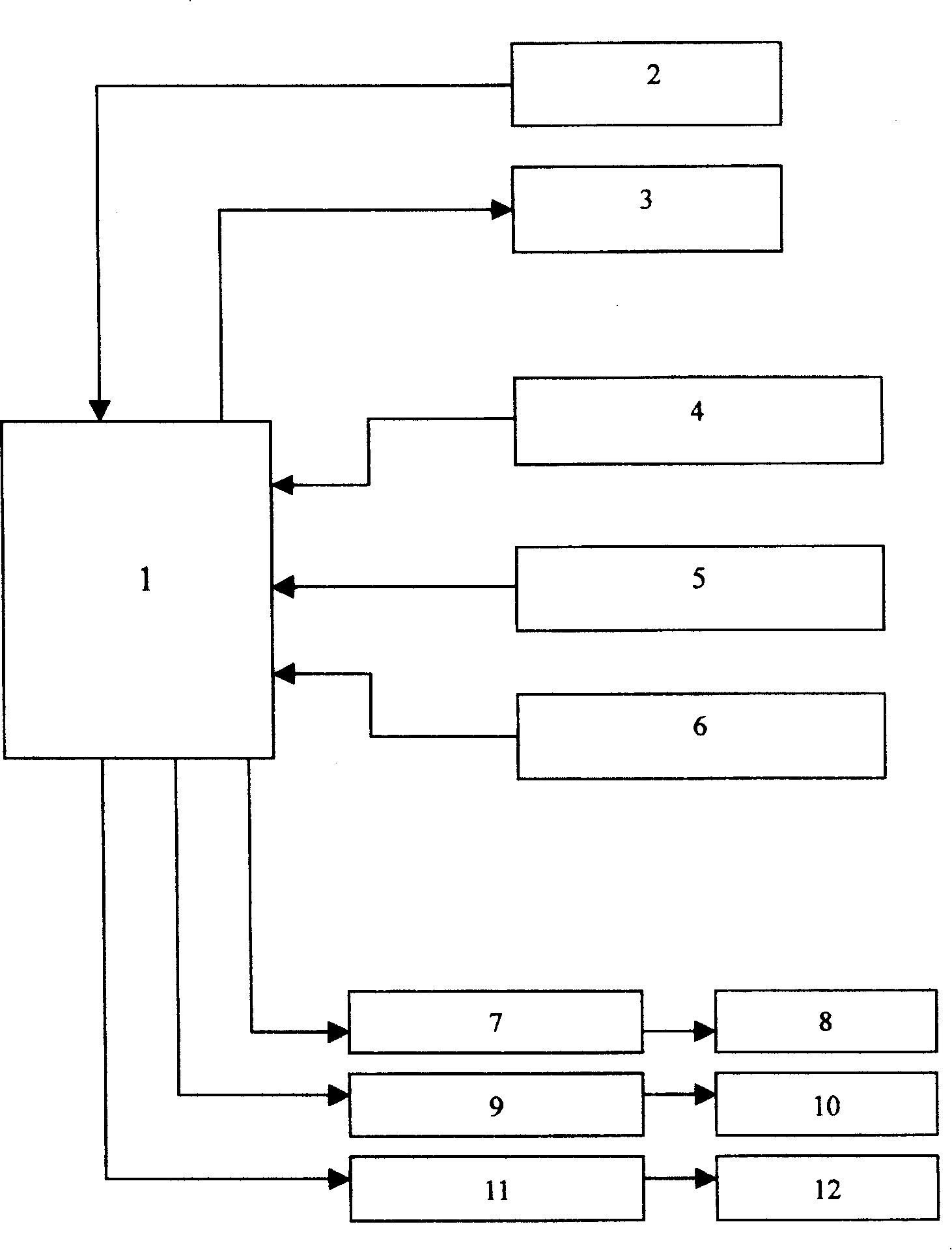

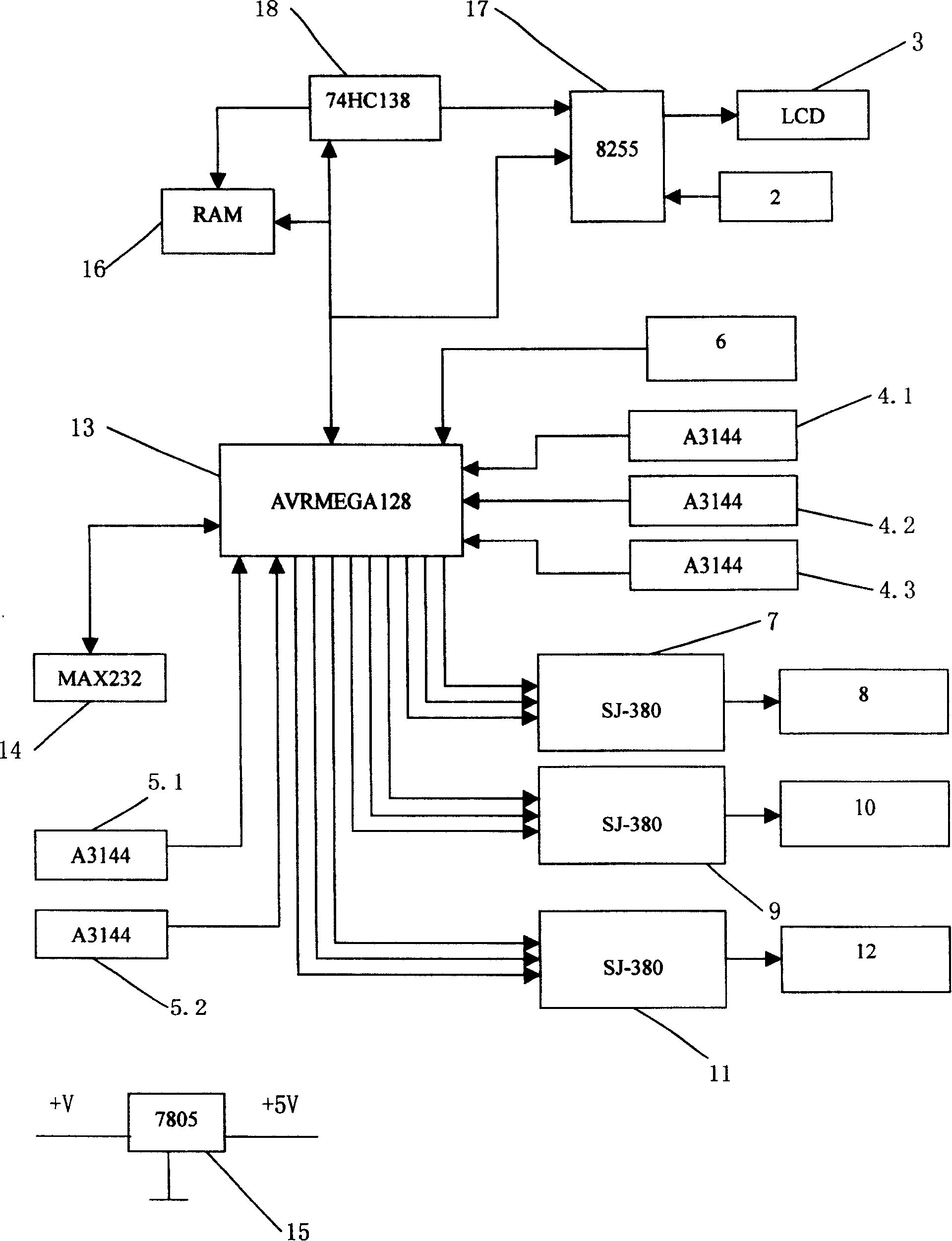

[0025] The control method provided by the present invention is to decompose the motion of the crystal ball placed on the grinding / polishing machine into motions in the directions of X, Y, and Z coordinate axes. Driven by a motor, and the angle or position of the three coordinate axes of X, Y, and Z is sensed by the angle or position sensor and fed back to the control device, and the control device is controlled according to the following steps:

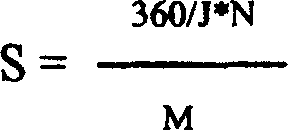

[0026] ①Initialize each parameter. The parameters mainly include the direction of each motor and the setting of the timer, the number of steps that the stepper motor needs to run in the X-axis direction, the number of X-axis planes, and the number of Y-axis planes. , the number of steps conversion of each axis surface angle, the number of steps on the Z-axis worktable, the number of slow-running steps, the number of height steps back to the table, the setting of dwell time and the communication rate of the serial interface; each axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com