Alarm device for servo pressure-preventing rake in thickener

The technology of an alarm device and concentrator is applied in the direction of chemical instruments and methods, separation methods, precipitation separation, etc. It can solve the problems of failure of the current detection method and failure of the pressure rake alarm function, so as to facilitate data analysis and solve the problem of alarm failure. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

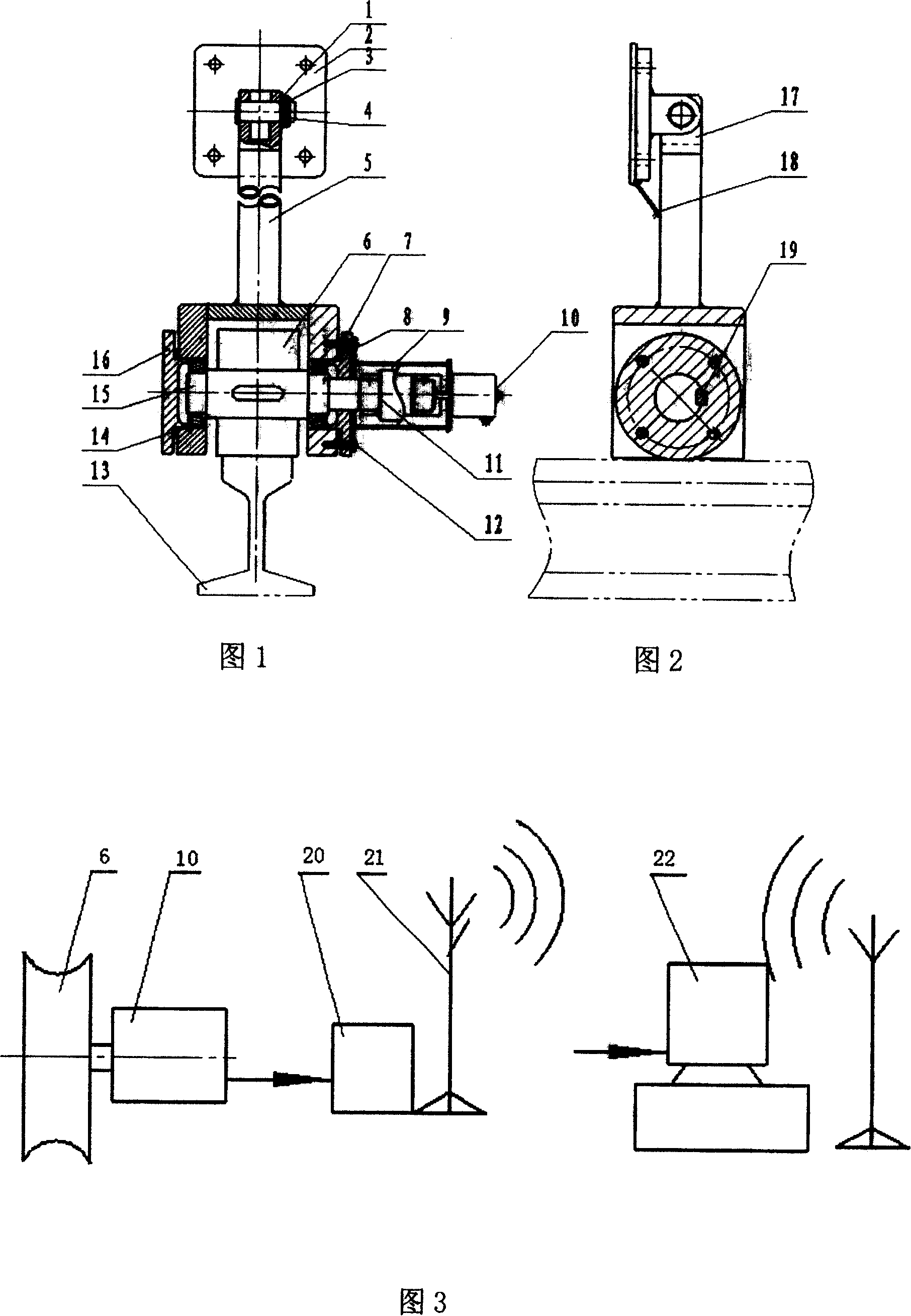

[0016] The invention includes a rake follow-up speed measuring mechanism and a control and alarm part of the concentrator.

[0017] The rake follow-up speed measuring mechanism of the concentrator mainly includes: connecting pulley 2, pin shaft 4, n-type coupling frame 5, follower wheel 6, bearing end cover 7, encoder coupling 9, encoder 10, plum blossom coupling 11 , transmission shaft 15, bearing transparent cover 7, shaft bracket U-shaped plug 17, spring 18,19: flat key.

[0018] The connecting plate 2 is connected to the rake of the concentrator by bolts, so that the follower wheel 6 whose surface is coated with polyurethane friction material can just be pressed onto the track of the concentrator. The pin shaft 4 connects the n-type coupling frame 5 and the connecting plate 2 together, and the n-type coupling frame 5 can rotate around the pin shaft 4 . The transmission shaft 15 connects the follower wheel 6 and the encoder 10 together. Tapered roller bearings 14 are insta...

Embodiment approach 2

[0023] The alarm method of the concentrator follow-up anti-pressure rake alarm device of the present invention takes the speed of the concentrator rake as the detection object, records the speed of the follower wheel 6 through the pulse encoder 10, and converts the pulse signal into an electrical signal through the signal conversion controller 20 , the electric signal passes the signal to the industrial control machine 22 through the wireless transmission station 21, and compares and judges whether to report to the police with the speed of the follower wheel 6 set in the alarm control program.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com