Solar energy high-temperature vacuum heat collection tube

A high-temperature vacuum and solar energy technology, which is applied in the field of solar thermal utilization, can solve the problems of Kovar alloy sealing process complexity, high cost, and vacuum failure, and achieve the effects of low cost, strong practicability, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

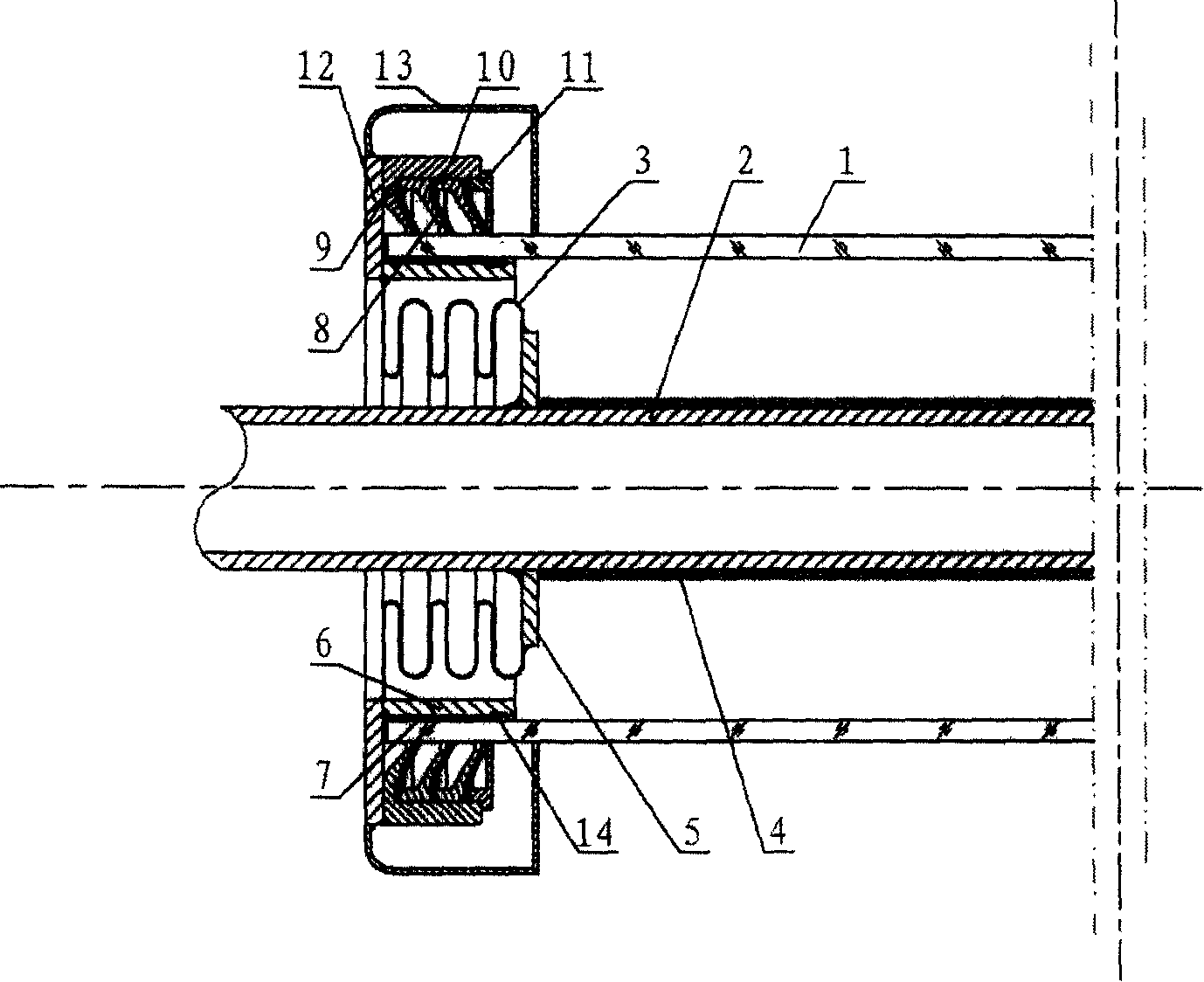

[0018] The structure of this embodiment is as figure 1 As shown, the solar high-temperature vacuum heat absorbing tube includes a glass sleeve 1, a heat-absorbing metal tube 2 coaxially installed inside the glass sleeve, and a corrugated compensator 3 between the two. The heat-absorbing metal pipe is coated with a high-temperature selective absorption coating 4, and there is a vacuum layer between the glass sleeve 1 and the heat-absorbing metal pipe 2, and the inner flange 5 sealed and welded to it is passed near the end of the heat-absorbing metal pipe 2 It is sealed and welded with one end of the corrugated compensator 3 (obviously, it is also feasible to directly seal and weld with one end of the corrugated compensator near the end of the heat-absorbing metal tube), and the transition between the other end of the corrugated compensator 3 and the glass sleeve 1 The ends of the metal tube 6 are sealed and welded, and the transition metal tube 6 and the glass casing 1 are nest...

Embodiment 2

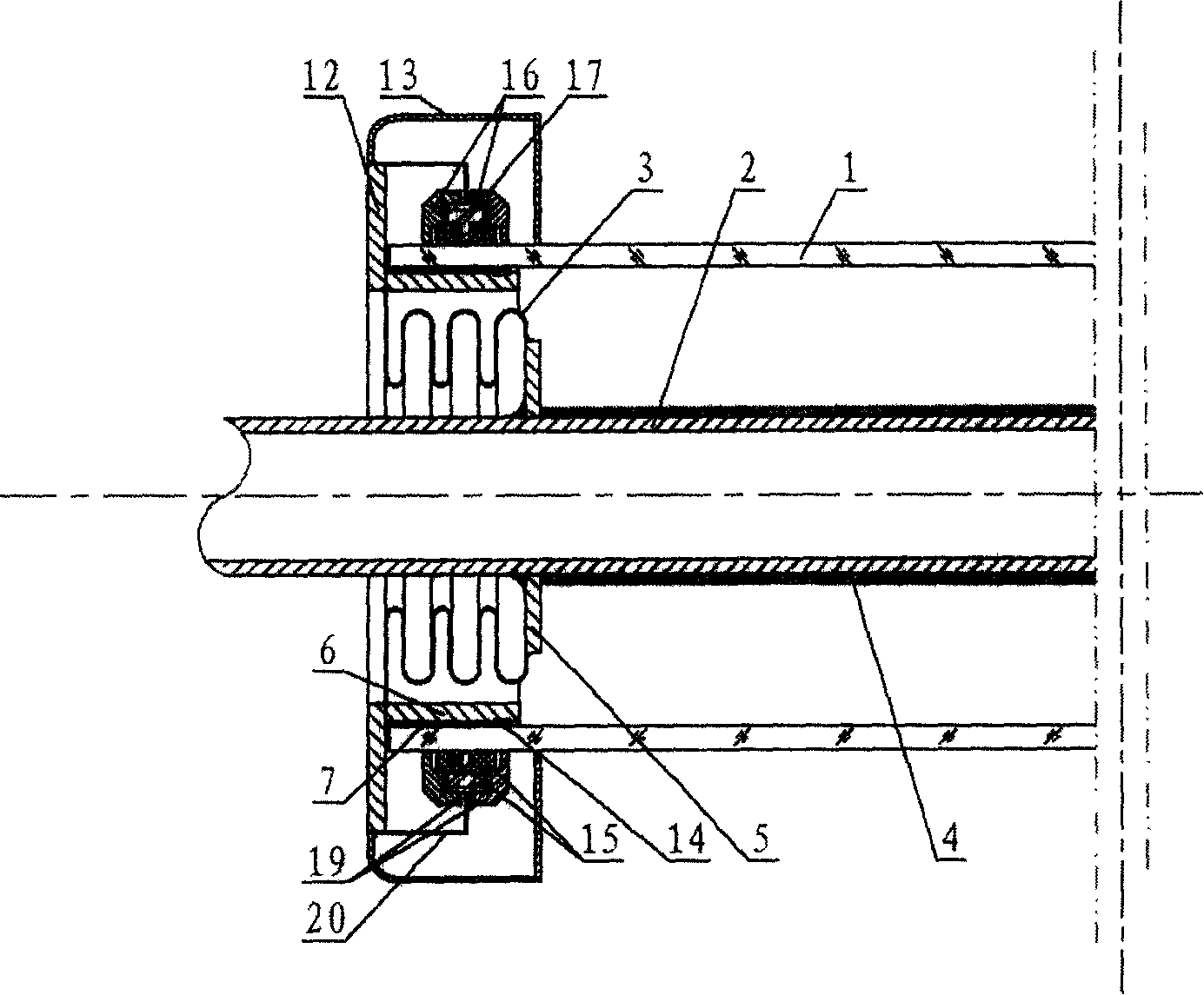

[0026] Such as figure 2 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, the main difference is: the inner edge of the turned back casing 20 welded and fixed with the flange cover 12 and the outer circle of the metal pipe 17 with a "T" cross-section in the axial direction Welding, the metal tube 17 is set outside the glass casing 1, and the vacuum seals are two wedge-shaped vacuum seal rings 15, which are respectively clamped in the depressions on both sides of the metal tube 17, and the pressing parts are made of conical, rectangular or arc-shaped These two nuts 16 are relatively screwed on the external thread of the metal pipe 17, and the two nuts 16 are respectively pressed against the exposed parts of the two wedge-shaped vacuum sealing rings 15 to form a reliable second seal (actual design , metal tube circumferential section is " L " shape, only a wedge-shaped vacuum sealing ring 15 is adorned, and it is obviously also feasible to co...

Embodiment 3

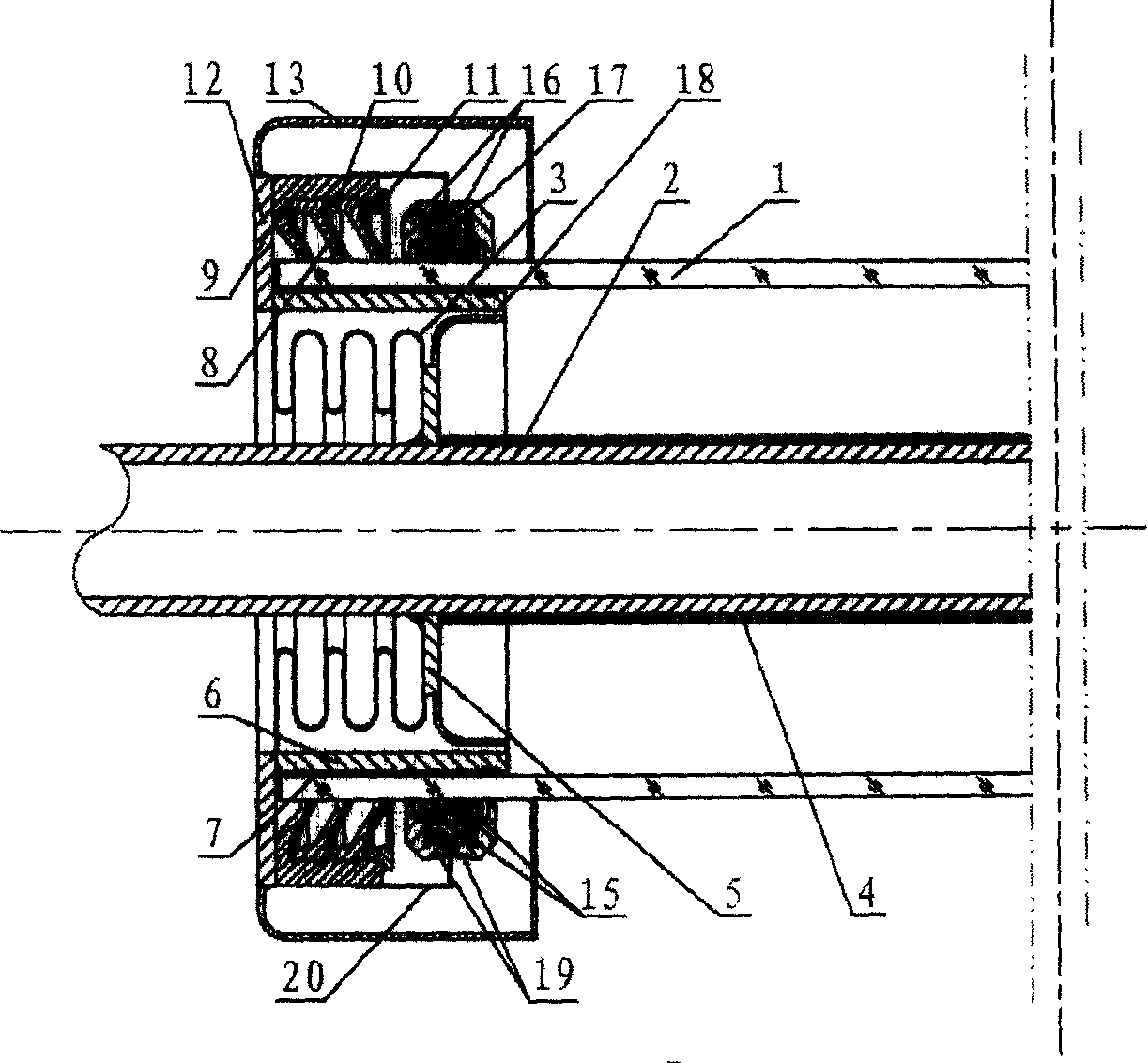

[0028] Such as image 3As shown, Embodiment 3 is essentially a combination of Embodiment 1 and Embodiment 2. The vacuum seal is composed of a cup 8 and a wedge-shaped vacuum seal 15. Other structures such as the cup 8 and the pressing parts of the vacuum seal 15 can be See descriptions of Examples 1 and 2. The metal pipe 17 with a "T" cross-section and the housing 9 supported by the leather cup 8 are connected by transition welding through the shell sleeve 20 .

[0029] In order to ensure the long-term sealing strength between the glass sleeve and the transition metal tube, the heat-resistant radiation cover 18 is welded on the inner flange 5 so that the seal is not subject to high-temperature internal heat radiation of the heat-absorbing metal tube 2, thereby blocking the radiation of the heat-absorbing metal tube Heat damages the seal. In this way, the sealing part is always in a relatively low temperature state, and the bonding part is protected to the greatest extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com