A light-emitting diode with electrode light output

A technology of light-emitting diodes and electrodes, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of increasing the light-emitting ability of the active layer and large light-shielding area, so as to improve the external quantum efficiency, reduce the light-shielding area, and reduce the working voltage the effect of the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The invention discloses a method for manufacturing a light-emitting diode with electrode light output, and the specific steps are as follows:

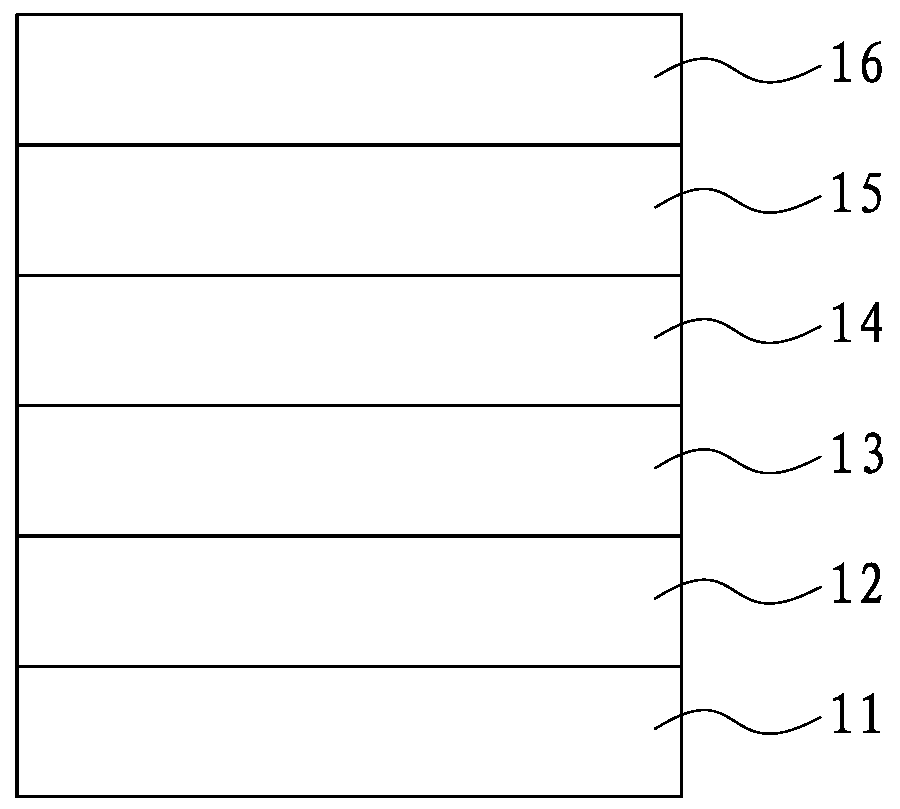

[0085] 1. On the epitaxial substrate 11, the peeling layer 12, the light-transmitting channel fabrication layer 13, the first-type conductive layer 14, the active layer 15, and the second-type conductive layer 16 are respectively epitaxially formed in sequence, such as figure 1 shown.

[0086] Wherein, the epitaxial substrate 11 is a GaAs substrate with a thickness of 300 μm. The peeling layer 12 is made of (Al 0.7 Ga 0.3 ) 0.5 In 0.5 Composed of P-35 compounds, and the thickness is 200nm. The constituent material of the transparent channel fabrication layer 13 is Al 0.4 Ga 0.6 As III-V compound, the thickness is 3 μm. The first-type conductive layer 14 is composed of a first-type rough layer, a first-type current spreading layer, and a first-type confinement layer. Among them, the first type of coarsening layer consist...

Embodiment 2

[0097] The invention discloses a method for manufacturing a light-emitting diode with electrode light output, and the specific steps are as follows:

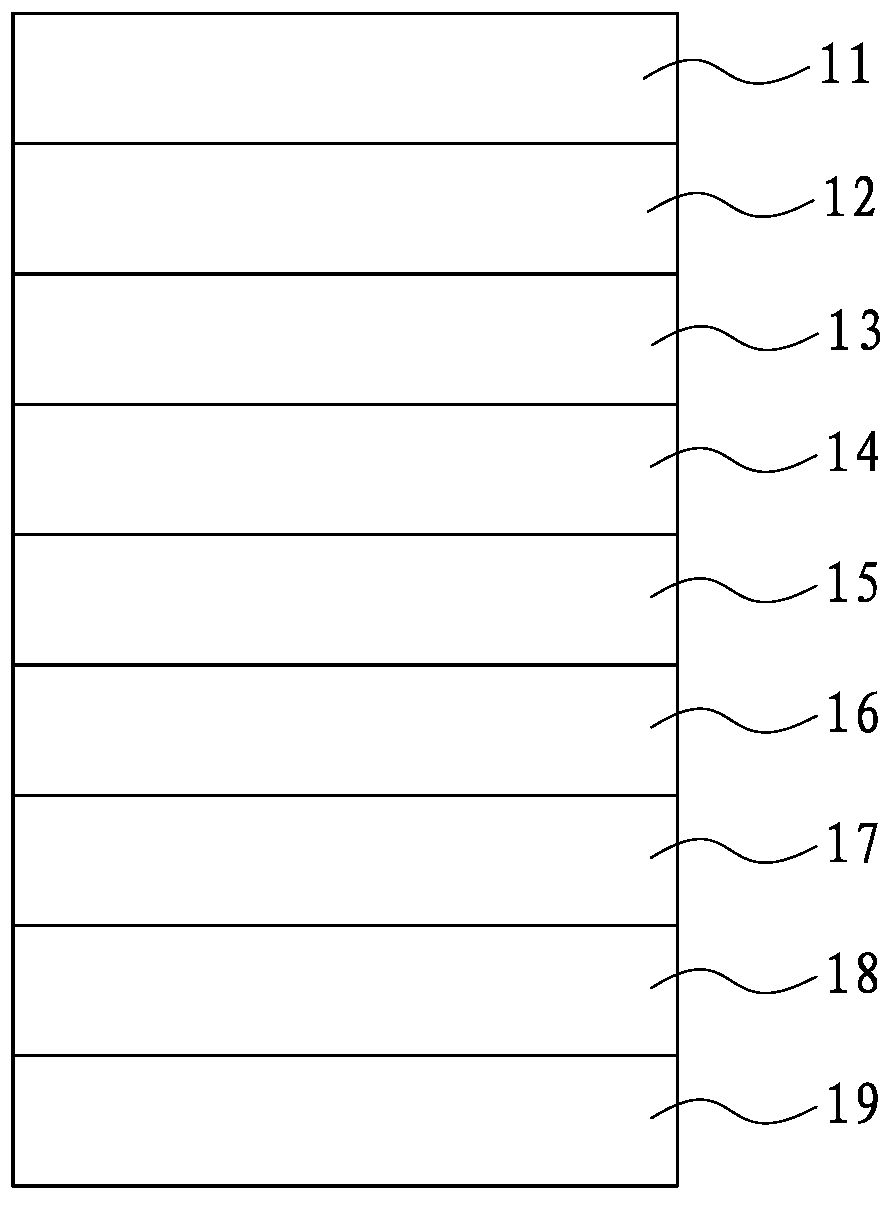

[0098] 1. On the epitaxial substrate 21, a buffer layer 22, a first-type conductive layer 23, an active layer 24, and a second-type conductive layer 25 are respectively epitaxially formed in sequence, such as Figure 7 shown.

[0099] Wherein, the epitaxial substrate 21 is a sapphire substrate with a thickness of 300 μm. The buffer layer 22 is made of undoped GaN III-V compound with a thickness of 2 μm. The first-type conductive layer 23 is made of Si-doped GaN III-V compound with a thickness of 2.5 μm. The active layer 24 adopts a cross-growth structure of five pairs of quantum wells and quantum barriers. Specifically, the quantum barrier is made of AlGaN III-V compound with a thickness of 12nm. The quantum well is composed of GaInN III-V compound with a thickness of 4nm. The second-type conductive layer 25 is made of Mg-d...

Embodiment 3

[0110] The invention discloses a method for manufacturing a light-emitting diode with electrode light output, and the specific steps are as follows:

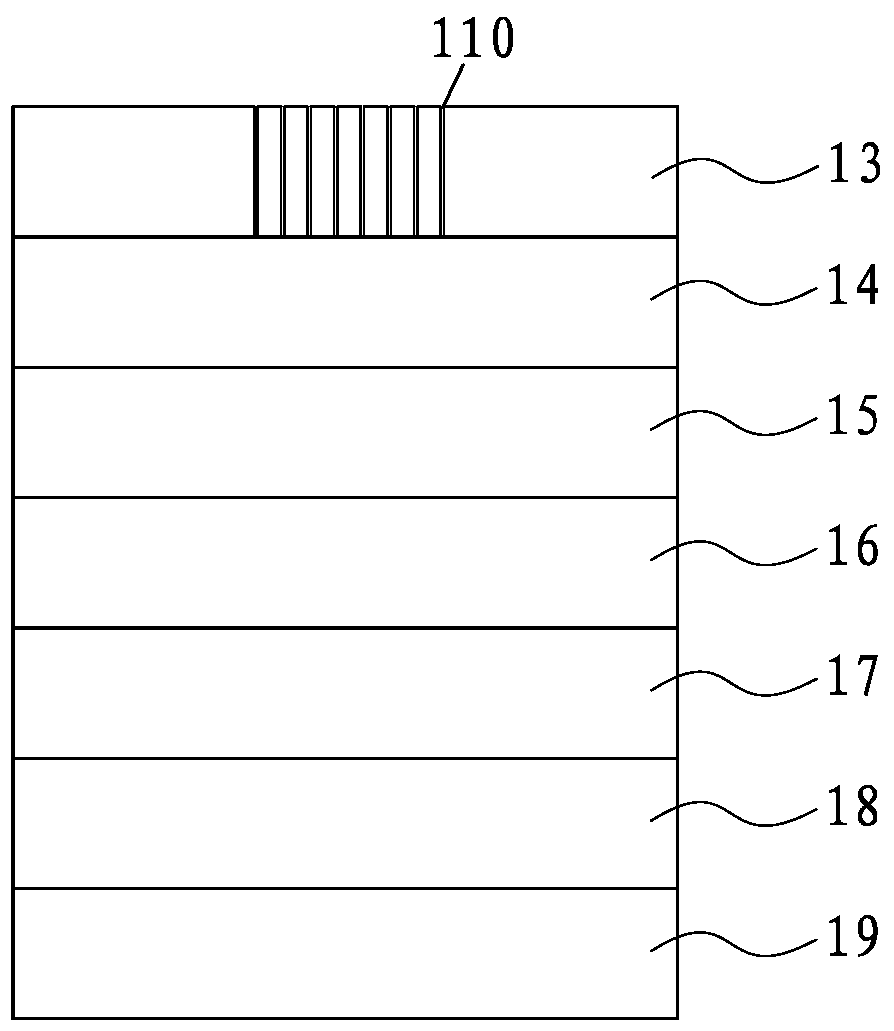

[0111] 1. On the epitaxial substrate 31, a buffer layer 32, a first-type conductive layer 33, an active layer 34, a second-type conductive layer 35, and a light-transmitting channel fabrication layer 36 are sequentially epitaxially formed, such as Figure 13 shown.

[0112] Wherein, the epitaxial substrate 31 is a GaAs substrate with a thickness of 300 μm. The first-type conductive layer 33 is composed of a Bragg reflection layer and a first-type confinement layer. Among them, the Bragg reflection layer is composed of 30 groups of Al 0.5 Ga 0.5 As / AlAs III-V compounds are alternately formed. The first-type confinement layer consists of (Al 0.7 Ga 0.3 ) 0.5 In 0.5 Composed of P-three and five-group compounds, and the thickness is 750nm. The active layer 34 is composed of 26 groups (Al 0.7 Ga 0.3 ) 0.5 In 0.5 P / Ga 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com