A semiconductor light emitting element

A technology of light-emitting components and semiconductors, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as aggravating current congestion and chip burns, achieve performance improvement, reduce the impact of brightness, and avoid the effect of overall widening design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

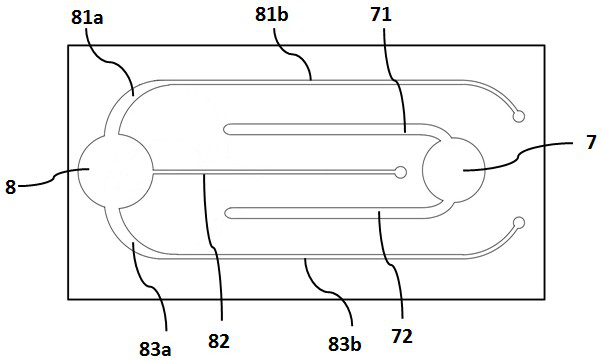

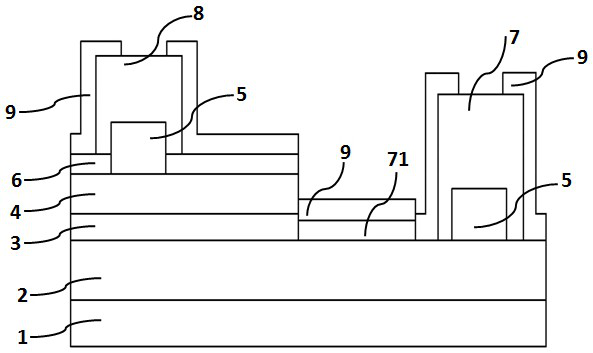

[0050] This embodiment provides the following semiconductor light emitting element, figure 2 It is a schematic cross-sectional view of a semiconductor light-emitting element, which includes: 1: substrate; 2: first conductivity type semiconductor layer; 3: active layer; 4: second conductivity type semiconductor layer; 5: current blocking layer; 6: transparent conductive layer ; 7: first electrode; 71, 72: first electrode lead; 8: second electrode; 81, 82, 83: second electrode lead; 9: insulating protective layer.

[0051] The substrate 1 can be an insulating substrate or a conductive substrate. Substrate 1 is a growth substrate for epitaxial growth of semiconductor barrier crystal stacks, including sapphire (Al 2 o 3 ) or spinel (MgA1 2 o 4 ) insulating substrates; silicon carbide (SiC), ZnS, ZnO, Si, GaAs, diamond; and oxide substrates such as lithium niobate and niobium gallate that match the nitride semiconductor lattice. The substrate 1 includes a first surface, a sec...

Embodiment approach

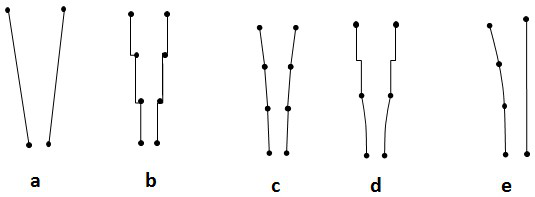

[0065] The second electrode 8 has a plurality of electrode leads, at least one second electrode lead, including a connection section connected to the second electrode, and an extension section extending from the connection section to the first electrode; the second electrode lead extends The segment has a first part extending from the second electrode lead connection segment to gradually approaching the first electrode and a second part extending from the first part gradually approaching the first electrode, and the width of the first part decreases gradually in the extending direction, so The width of the second part is fixed. As an embodiment of the present invention, the width of the first part of the second electrode extension section can be linearly narrowed at a fixed rate of change from the extension direction, such as image 3 As shown in a; as another embodiment of the present invention, the width of the first part of the second electrode extension section can be narr...

Embodiment 2

[0084] In this embodiment, if Figure 9 As shown, the difference from Embodiment 1 is that the two lead wires 81 and 83 of the p-electrode in this embodiment have no ends as in Embodiment 1, and other parts are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com