Radiator valve

A technology of heating body and shell, applied in heating mode, lighting and heating equipment, lift valve, etc., can solve problems such as changing valve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

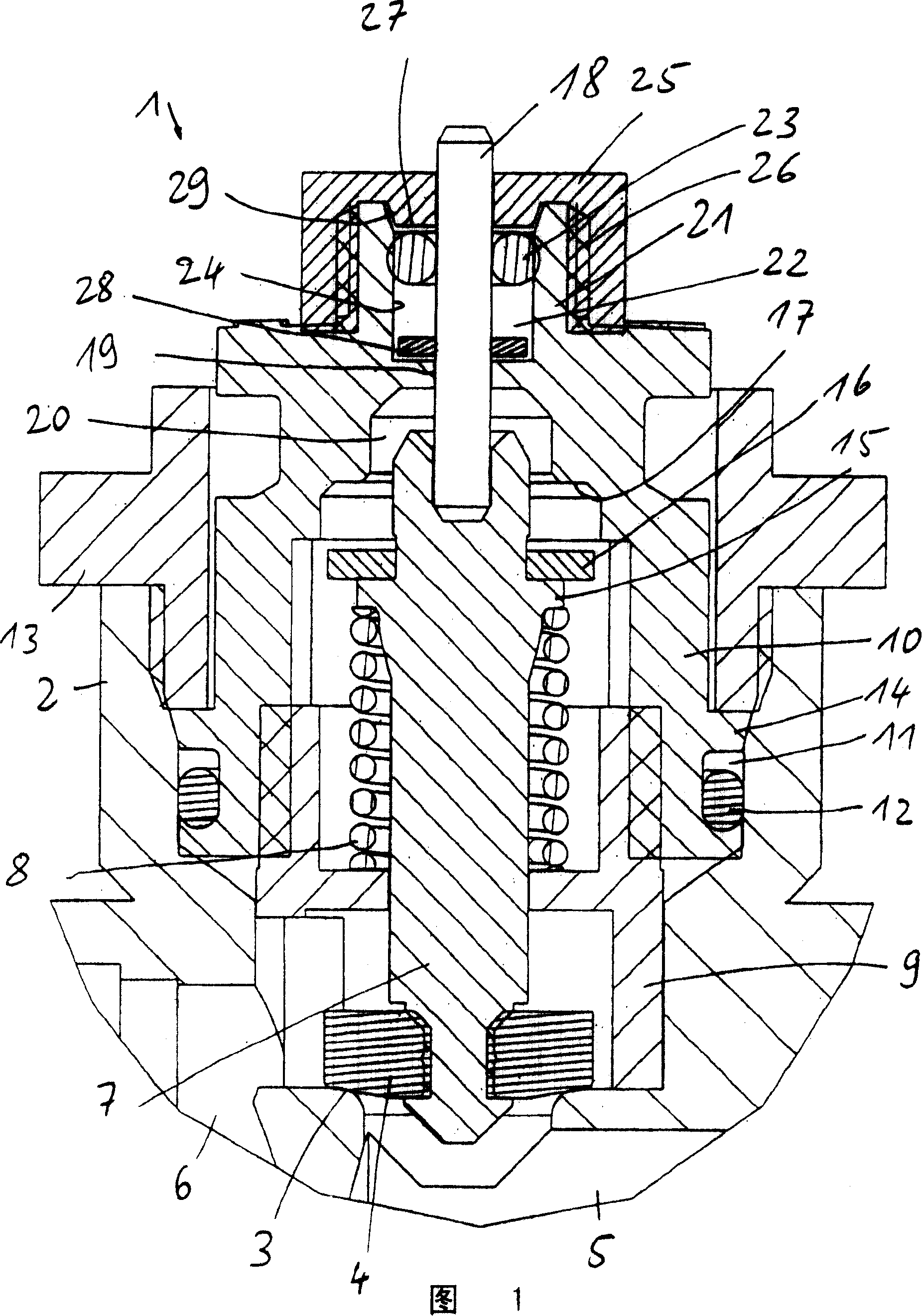

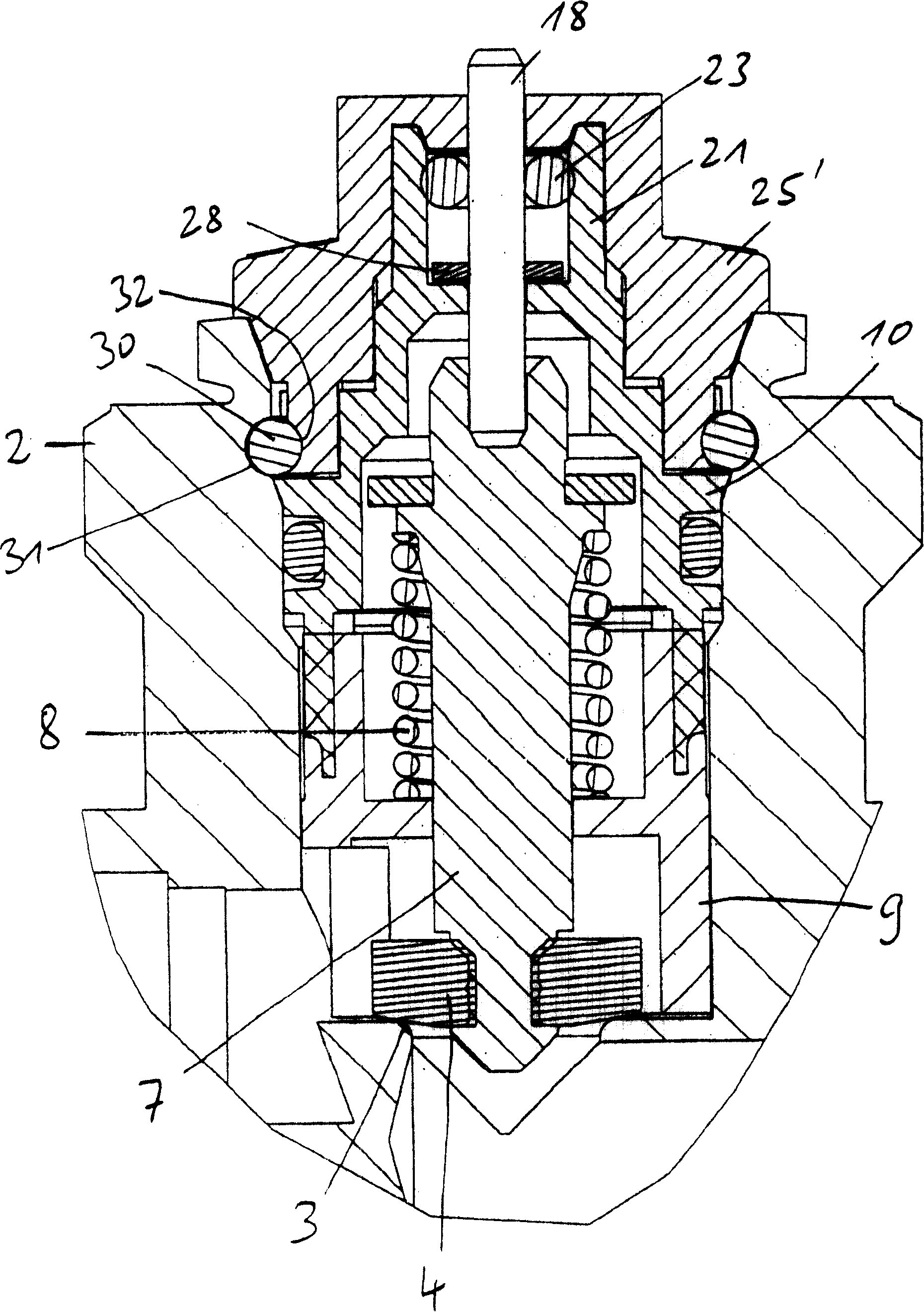

[0027] A heater valve 1 has a housing 2 in which a valve seat 3 is arranged and a valve element 4 cooperates with the valve seat 3 . The valve element 4 together with the valve seat 3 forms a fluid flow control for a heat transfer medium fluid from an inlet 5 to an outlet 6 . Furthermore, the amount of fluid flowing through depends on the distance between the valve element 4 and the valve seat 3 .

[0028] The valve element 4 is held on a valve stem 7 which is prestressed in the opening direction by a spring 8 . The spring 8 is supported here on an insert 9 which is arranged in the housing 2 .

[0029] A cup-shaped housing part 10 covers the insert part 9 and rests in a gap 11 between the housing 2 and the insert part 9 . The housing part 10 is sealed here by a seal 12 . The housing part 10 is fastened in the housing 2 via a sleeve 13 , the sleeve 13 being screwed into the housing 2 and engaging a surrounding projection 14 of the housing part 10 .

[0030]The valve stem 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com