Winding spindle for producing cross wound package textile machine

A technology for cross-winding bobbins and textile machines, applied in the field of winding spindles, can solve problems such as inapplicability, and achieve the effect of reducing yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

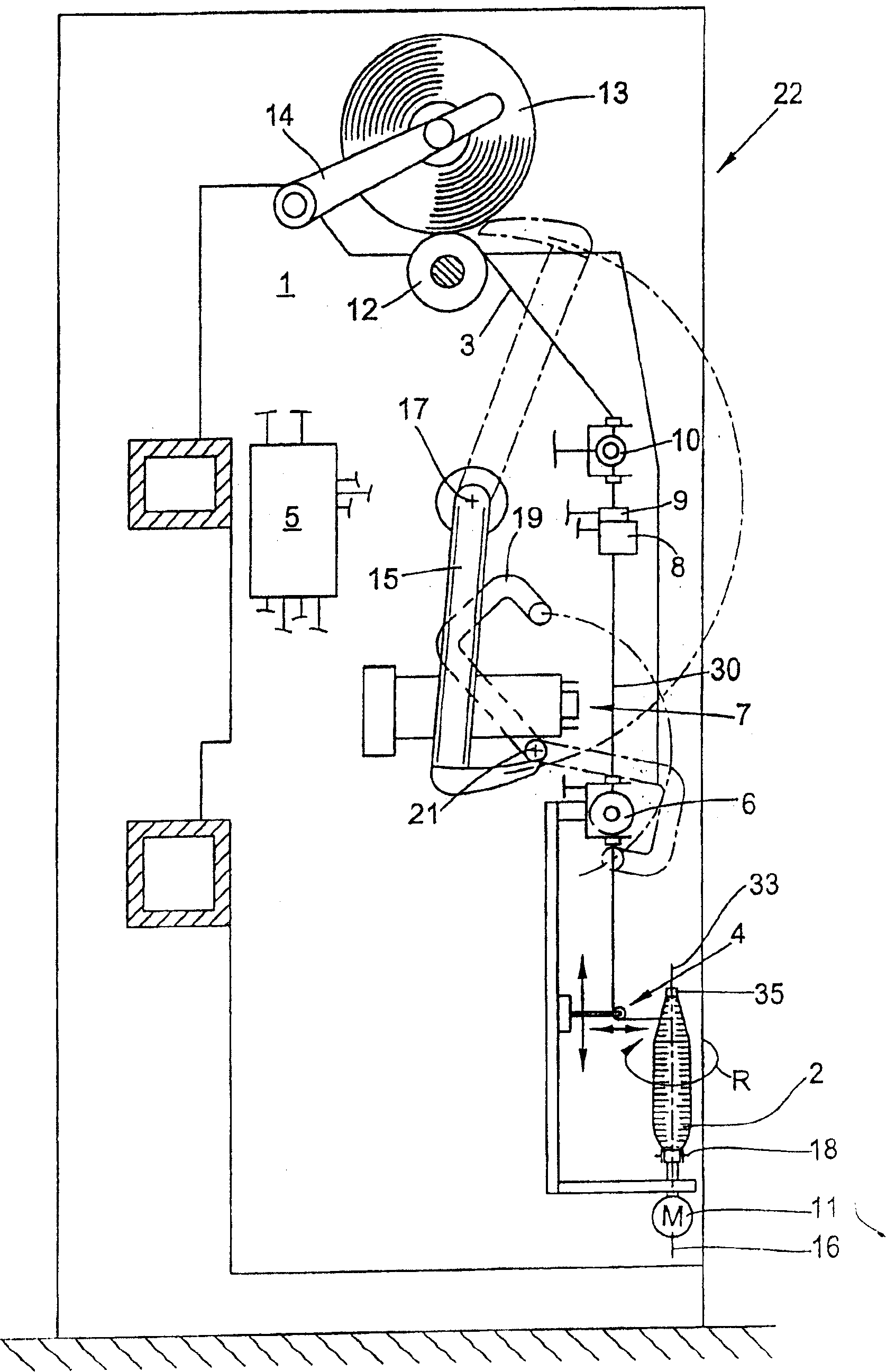

[0045] figure 1 A side view of a winding spindle of a textile machine for producing cross-wound bobbins, generally designated by the reference numeral 22, is shown.

[0046] Such textile machines, above all automatic winders, usually have a number of working spindle positions 1 arranged in a row.

[0047] Yarn feed bobbins 2, usually bobbins produced, for example, by a ring spinning machine (not shown), are wound on these working spindles 1 into high-capacity cross-wound bobbins 13 .

[0048] For this purpose, the working position 1 is equipped with various known, and therefore only schematically represented, yarn handling devices and detection devices, which are each defined by the working position's own control device, a so-called winding position computer 5. control.

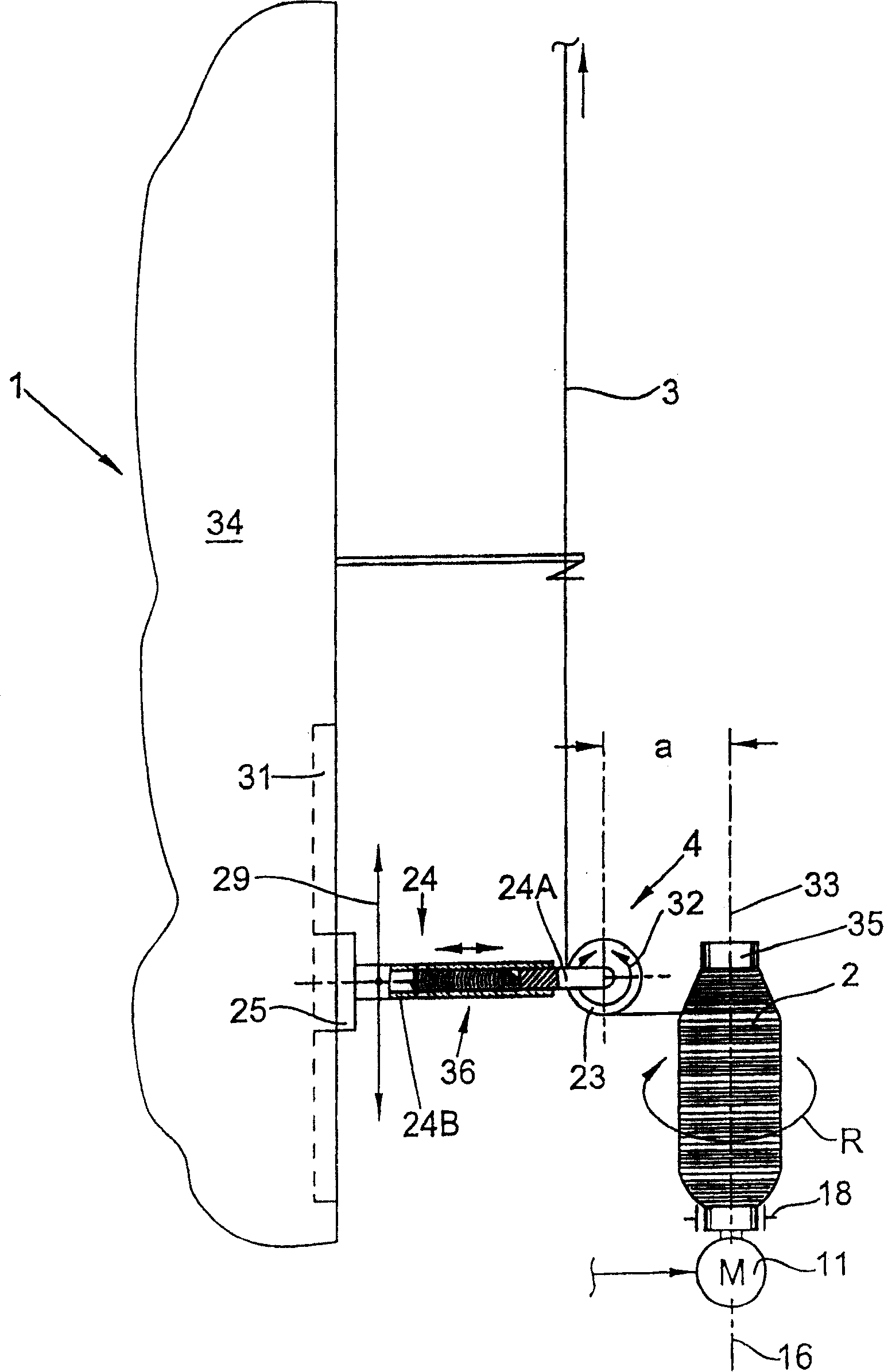

[0049] The yarn 3 unwound from the yarn feeding bobbin 2 is at first passed through the yarn unwinding device 4 according to the present invention, runs to the cross-winding bobbin 13 according to its yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com