Continuous firing furnace with treatment unit for exhausted gas

A technology of exhaust gas and processing unit, which is applied in the field of continuous firing furnace, and can solve the problems of high combustion efficiency, pollution of fired product quality, inability to grasp and adjust binder volatiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

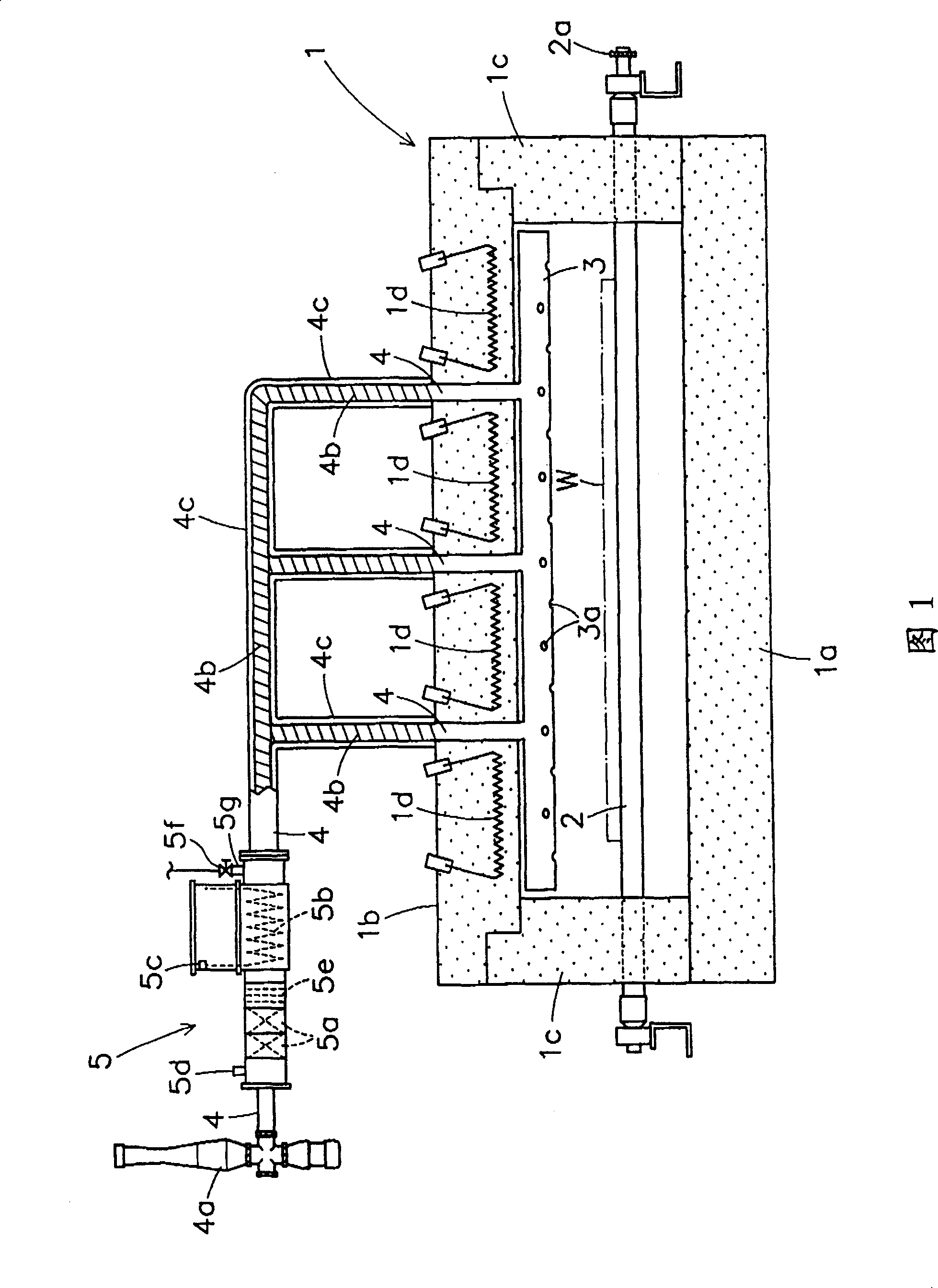

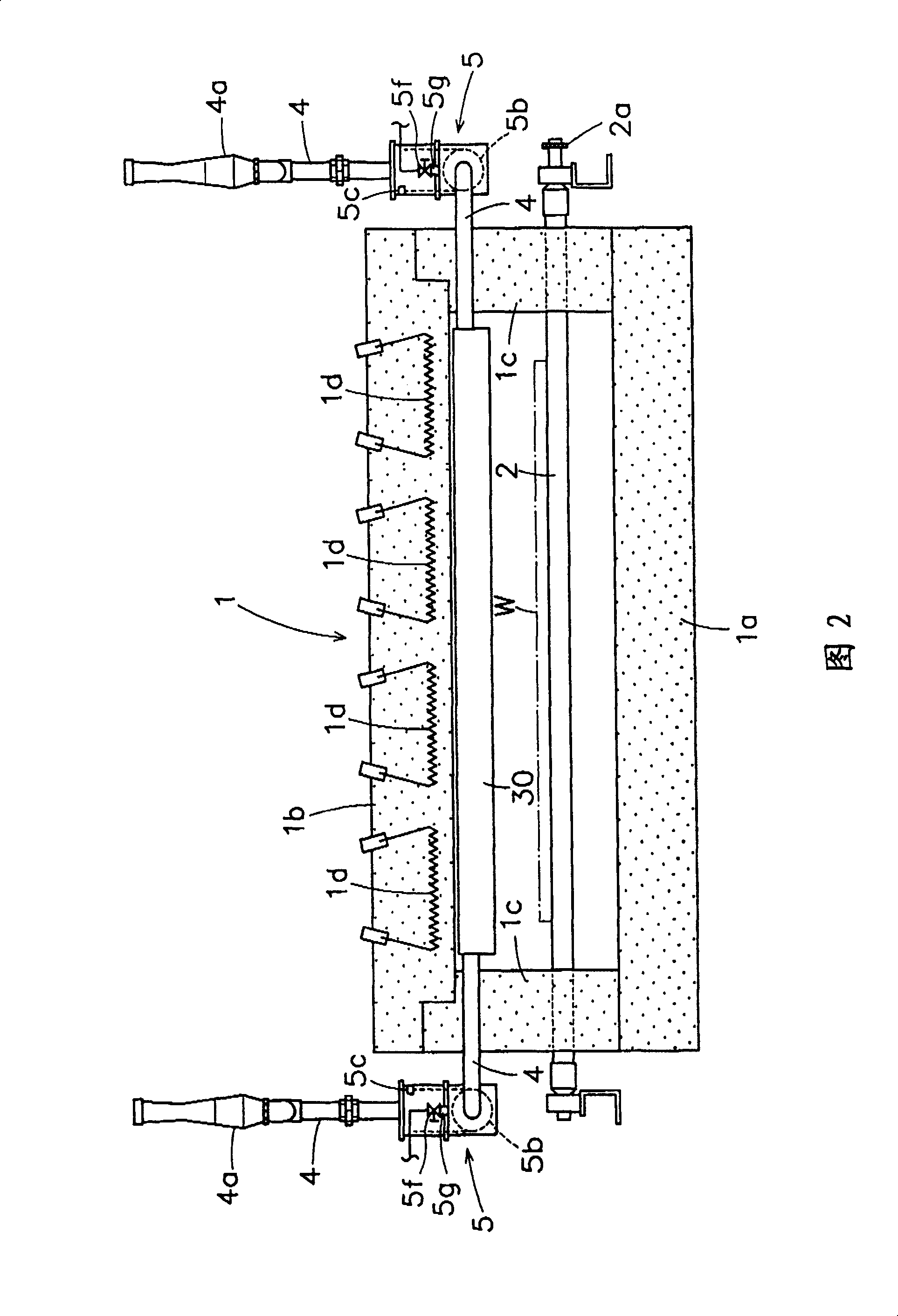

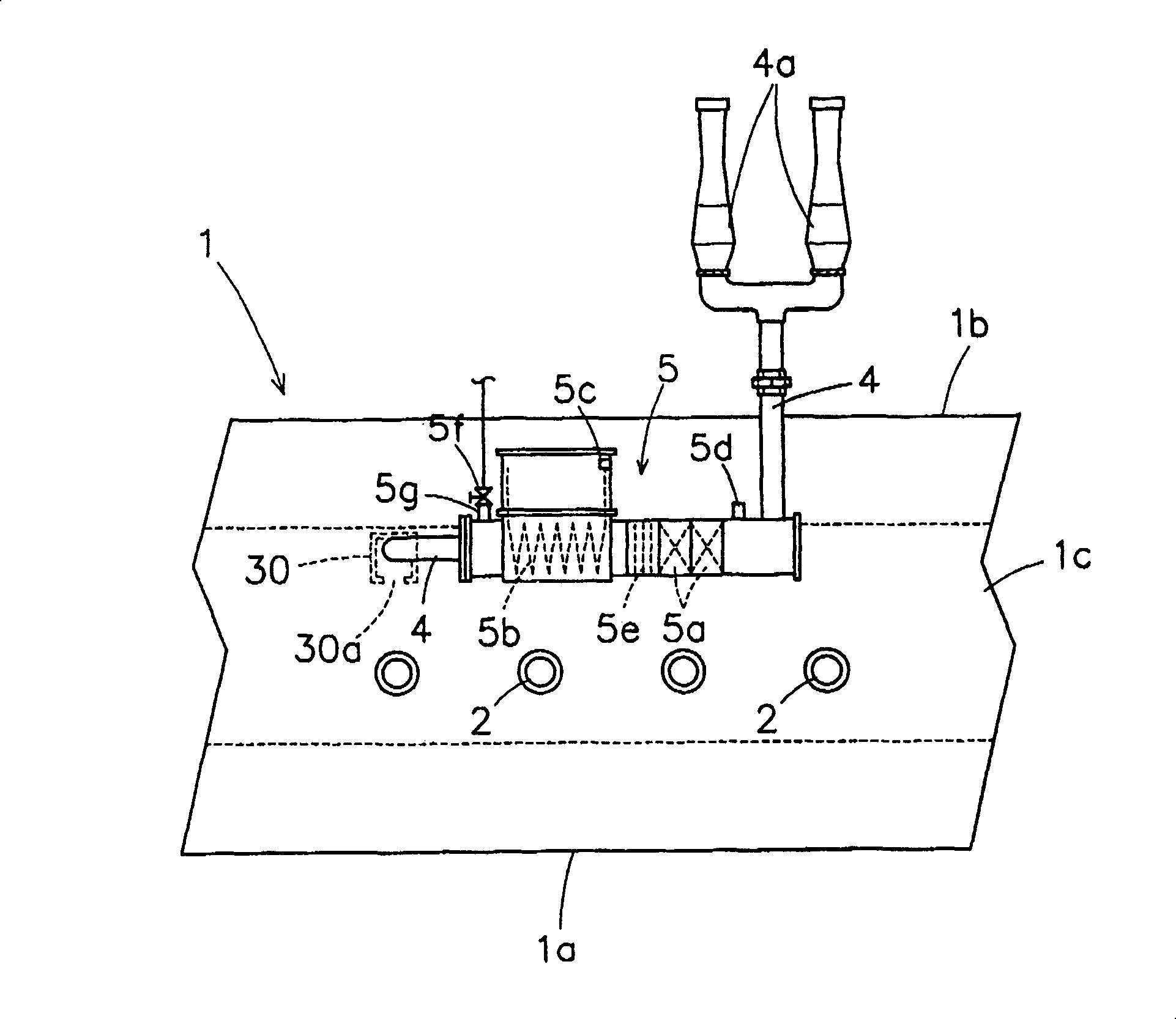

[0019] Fig. 1 is a schematic cross-sectional view showing an embodiment of a continuous firing furnace with an exhaust gas treatment unit according to the present invention.

[0020] This continuous firing furnace with an exhaust gas treatment unit is formed of a bottom wall 1a, a top wall 1b, and left and right side walls 1c, 1c made of a thick-walled hard heat insulating material made of vacuum-formed ceramic fibers. The furnace body 1 having a flat rectangular parallelepiped shape is heated inside the furnace body by a plurality of electric heaters 1d embedded in the ceiling wall 1b and the like.

[0021] The furnace body 1 is formed to be long in the front-rear direction (direction perpendicular to the paper surface in FIG. 1 ), and a plurality of conveying rollers 2 are arranged at regular intervals in the front-rear direction, penetrating the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com