Sedimentation pond for water treatment and mud-scraping machine

A sludge scraper and sedimentation tank technology, applied in the field of rotary sludge scraper and square sedimentation tank, can solve the problems that the sludge cannot be scraped in a square trajectory, and the rotary sludge scraper can only scrape sludge in a circle, so as to achieve high land utilization rate. , good hydraulic properties and precipitation effect, the effect of improving processing capacity and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

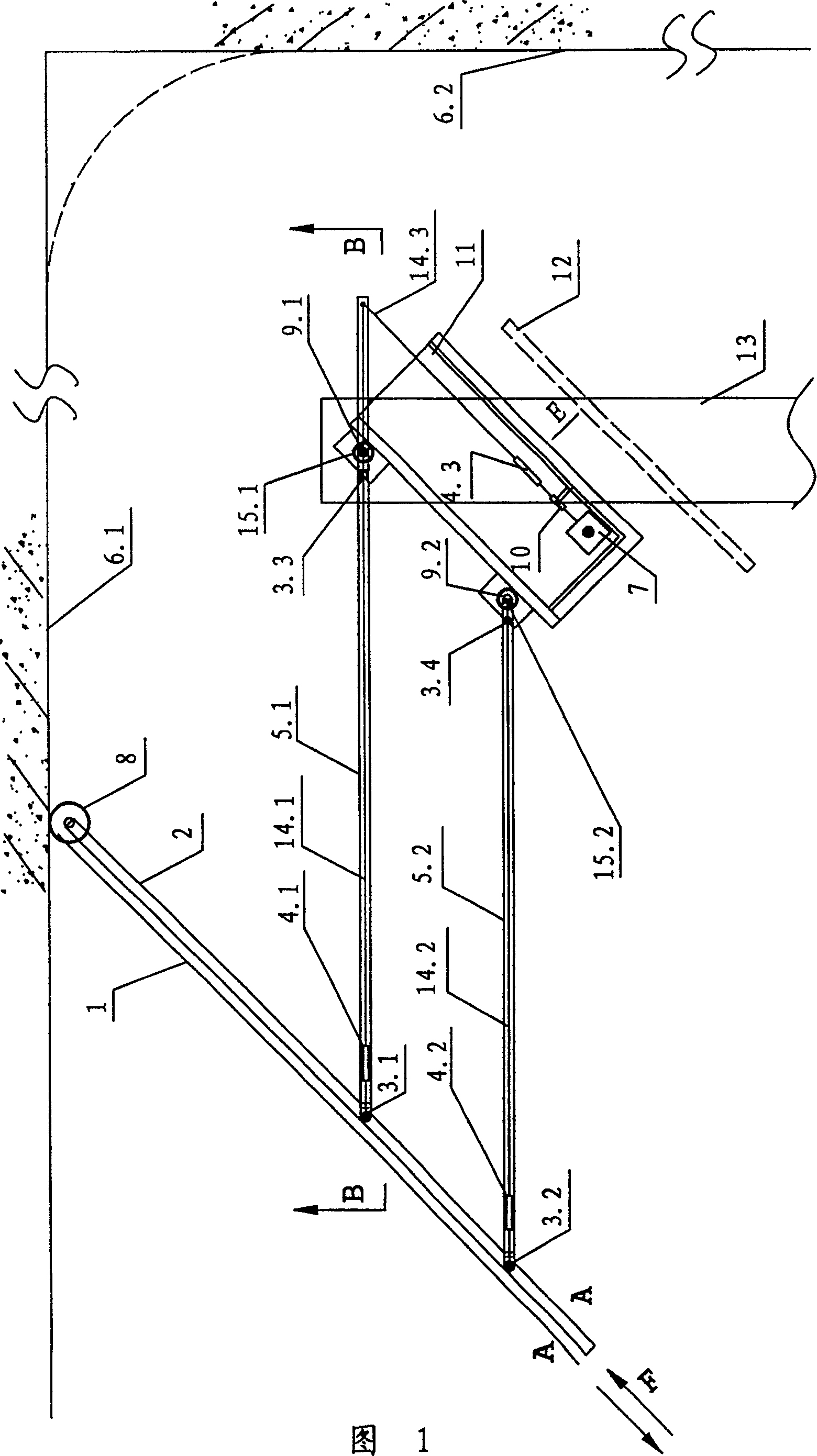

[0021] Embodiment 1: referring to Fig. 1-4, the side length 6 of the water treatment sedimentation tank is a circular circumscribed square, and each adjacent surface is perpendicular to each other, and the center has the same central water distribution pillar similar to the circular sedimentation tank (not shown in the figure ), the bottom of the pool is inclined towards the center, and the pool body is equipped with a rotary mud scraper.

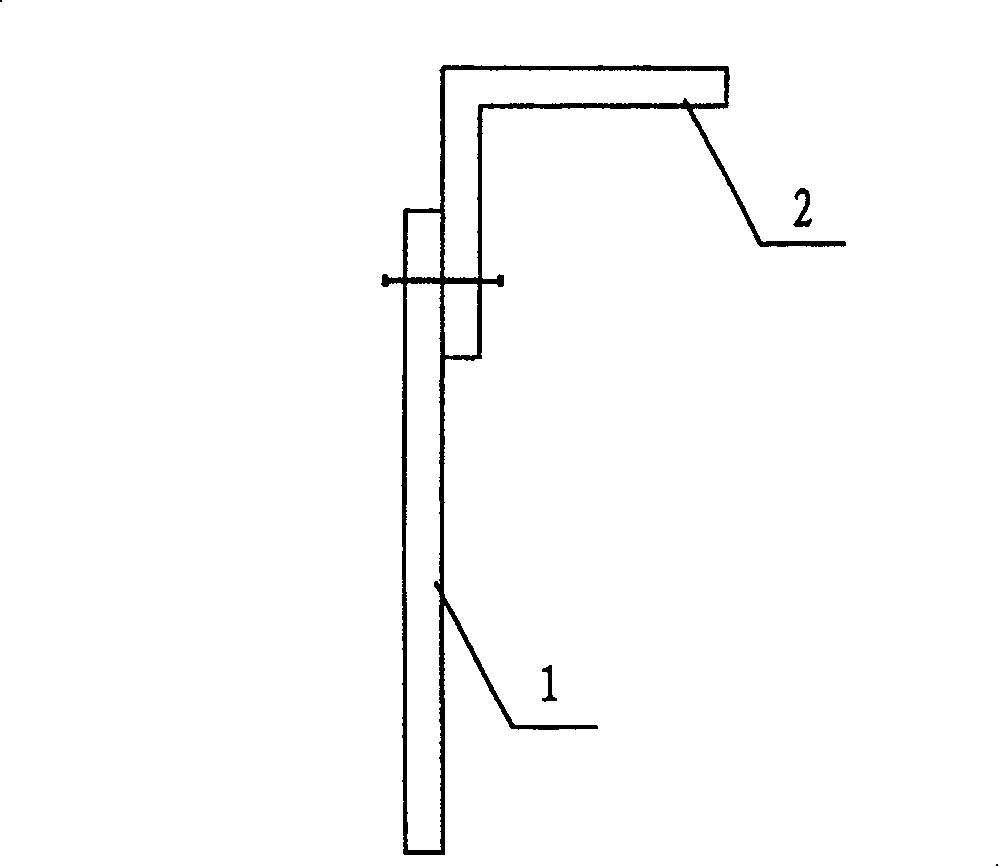

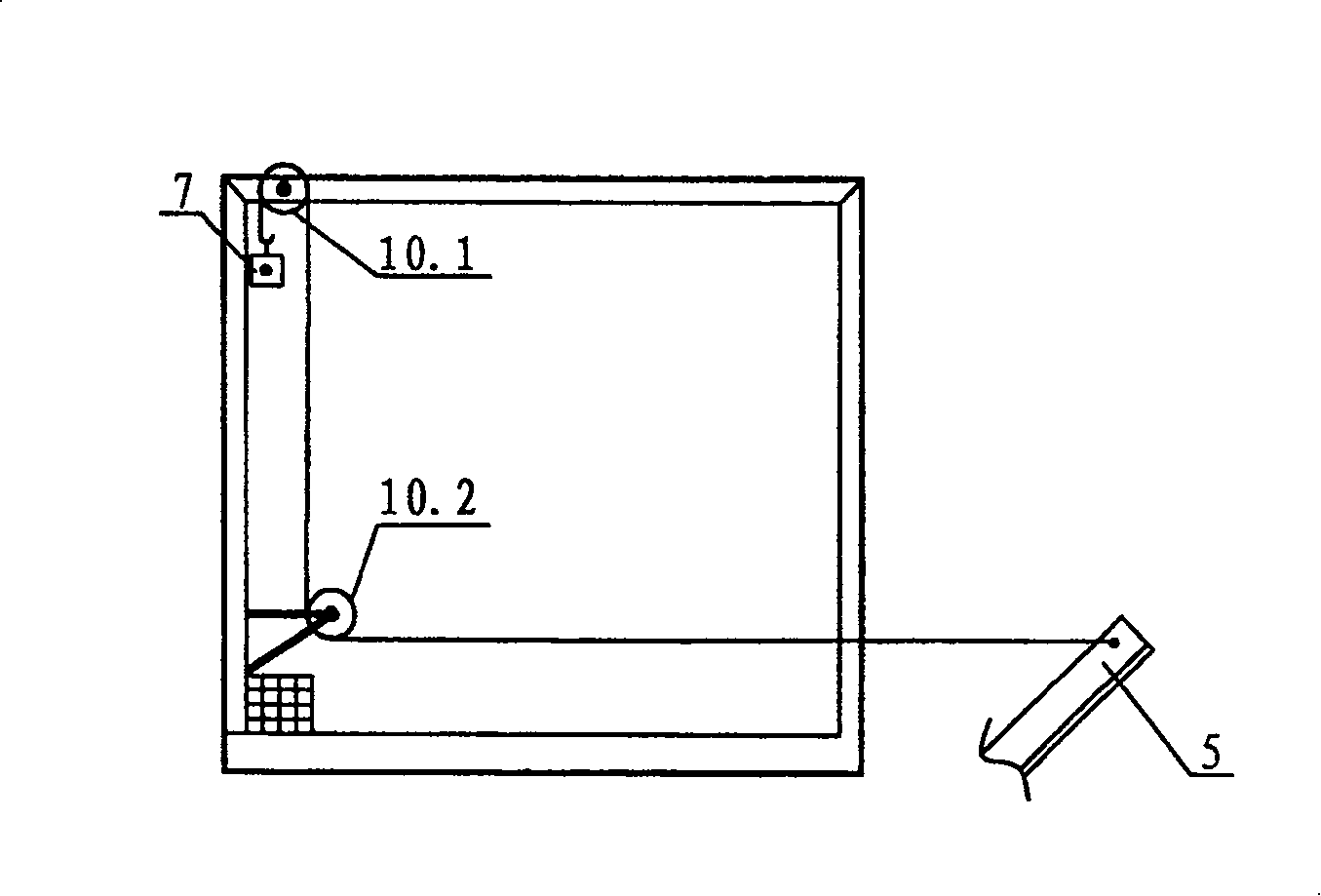

[0022] There are several main scrapers 12 on the scraper arm 13 of the rotary mud scraper, and there are vertical inclined supports 11 arranged obliquely at 45°±2° near both ends, and there are vertical shafts on the scraper arm and the inclined supports 9.1 and 9.2 and rotating sleeve 15.1 and 15.2 constitute rotating hinge 3 (Fig. 1, 4). The parallelogram mechanism composed of rods 5 and 2 is movable and hinged on the scraper arm 13 and the oblique support 11 through two living hinges 3 parallel to the pool plane, wherein the parallelogra...

Embodiment 2

[0023] Embodiment 2: referring to Fig. 5, as embodiment 1, omit gravity counterweight, a fixed rod 17 is set on scraper 13 upper arm, extension spring 16 is set between rod 17 and parallelogram bar 5.1, the pulling force that extension spring produces, same The parallelogram mechanism can always be kept outwardly stretched and deformed, so that the roller 8 at the opposite end of the rod member 2 of the parallelogram scraper arm can always keep sticking to the wall surface of the pool.

Embodiment 3

[0024] Embodiment 3: Referring to Fig. 6, as in Embodiment 1, the gravity counterweight is omitted, and a guide groove 18 is provided on the peripheral surface 6 of the pool wall, so that the end of the parallelogram scraper arm opposite to the rod 2 is movable into the guide groove through the roller 19 , the parallelogram mechanism can also be kept stretched and deformed all the time, so that the parallelogram scraper arm facing bar 2 can always keep sticking to the wall of the pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com