Building dock

A dock chamber and dock wall technology, which is applied in the field of shipbuilding docks, can solve the problems of large segmental movement difficulties, influence of shipbuilding efficiency, and insufficient operating efficiency, so as to avoid repeated hoisting and alignment operations, convenient energy supply, and easy installation. just easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

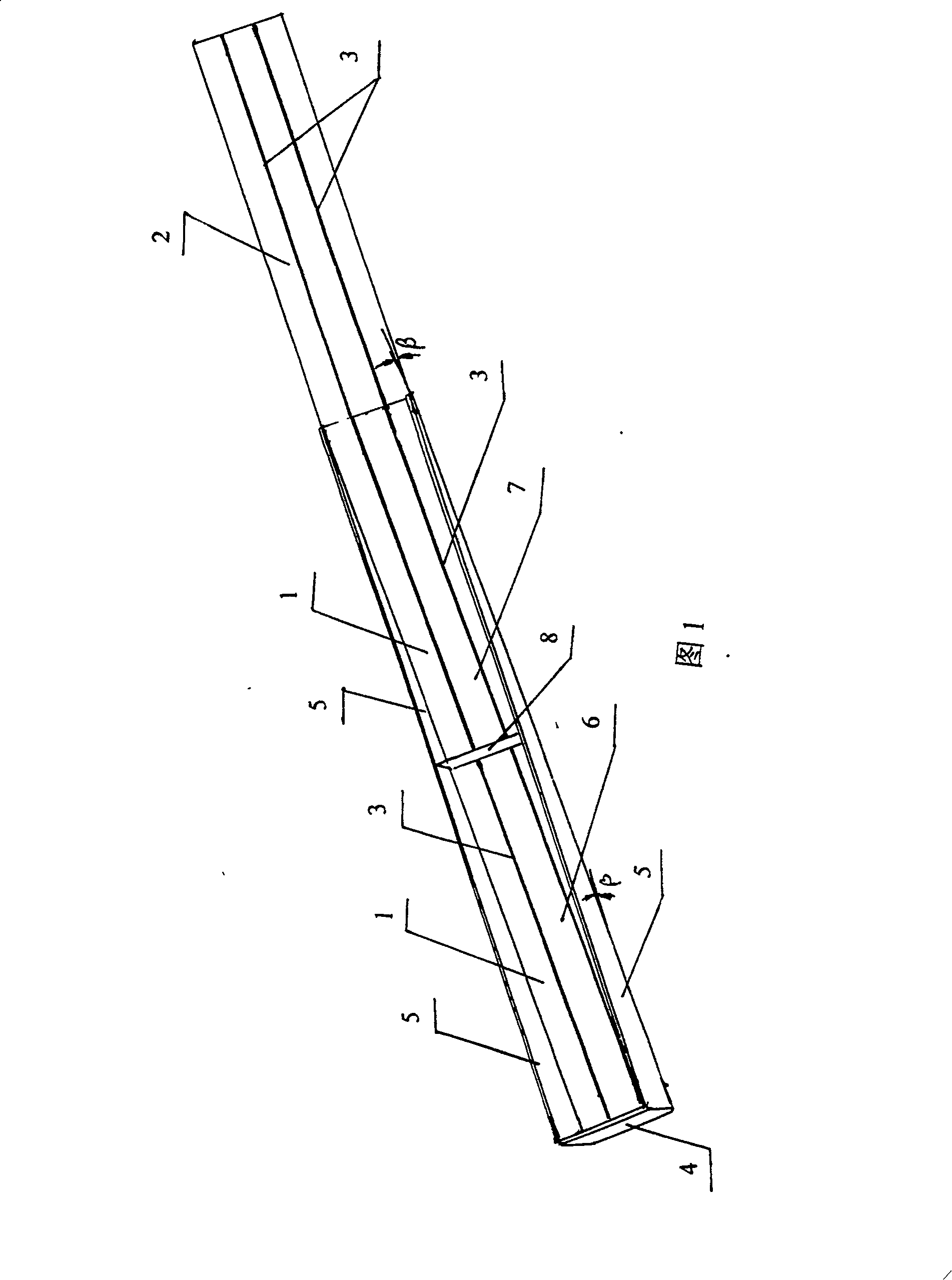

[0015] As shown in Fig. 1, a shipbuilding dock is composed of a front dock door 4, dock walls 5 on both sides, and a dock floor 1 to form a dock chamber 6. The dock walls 5 on both sides extend backward to form a rear dock chamber 7, the rear end of the rear dock chamber 7 is connected to the horizontal ground slipway 2, and two or more load-bearing rails 3 run through the dock floor 1 and the ground slipway 2 .

[0016] There can be a middle dock door 8 between the dock chamber 6 and the rear dock chamber 7.

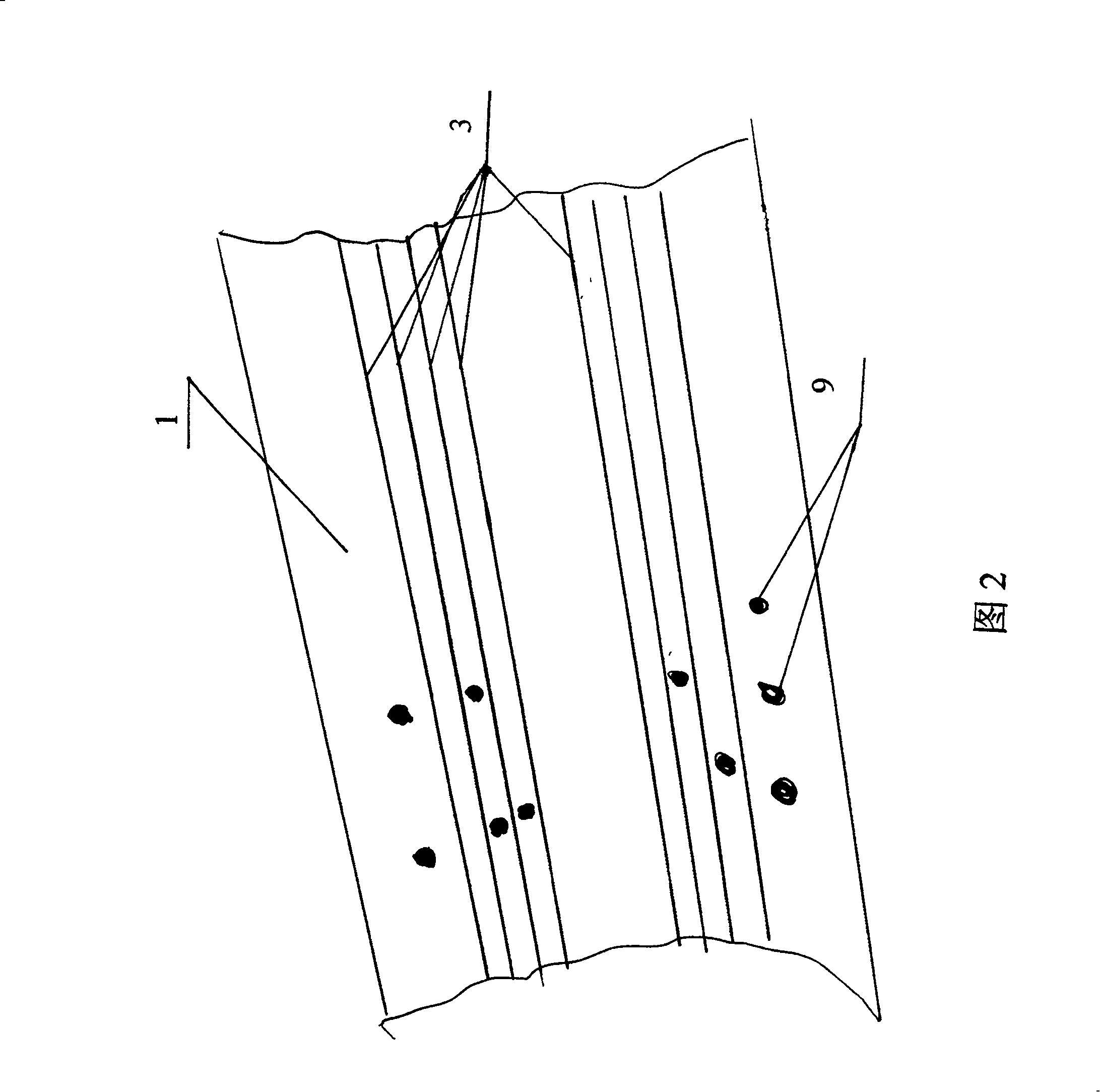

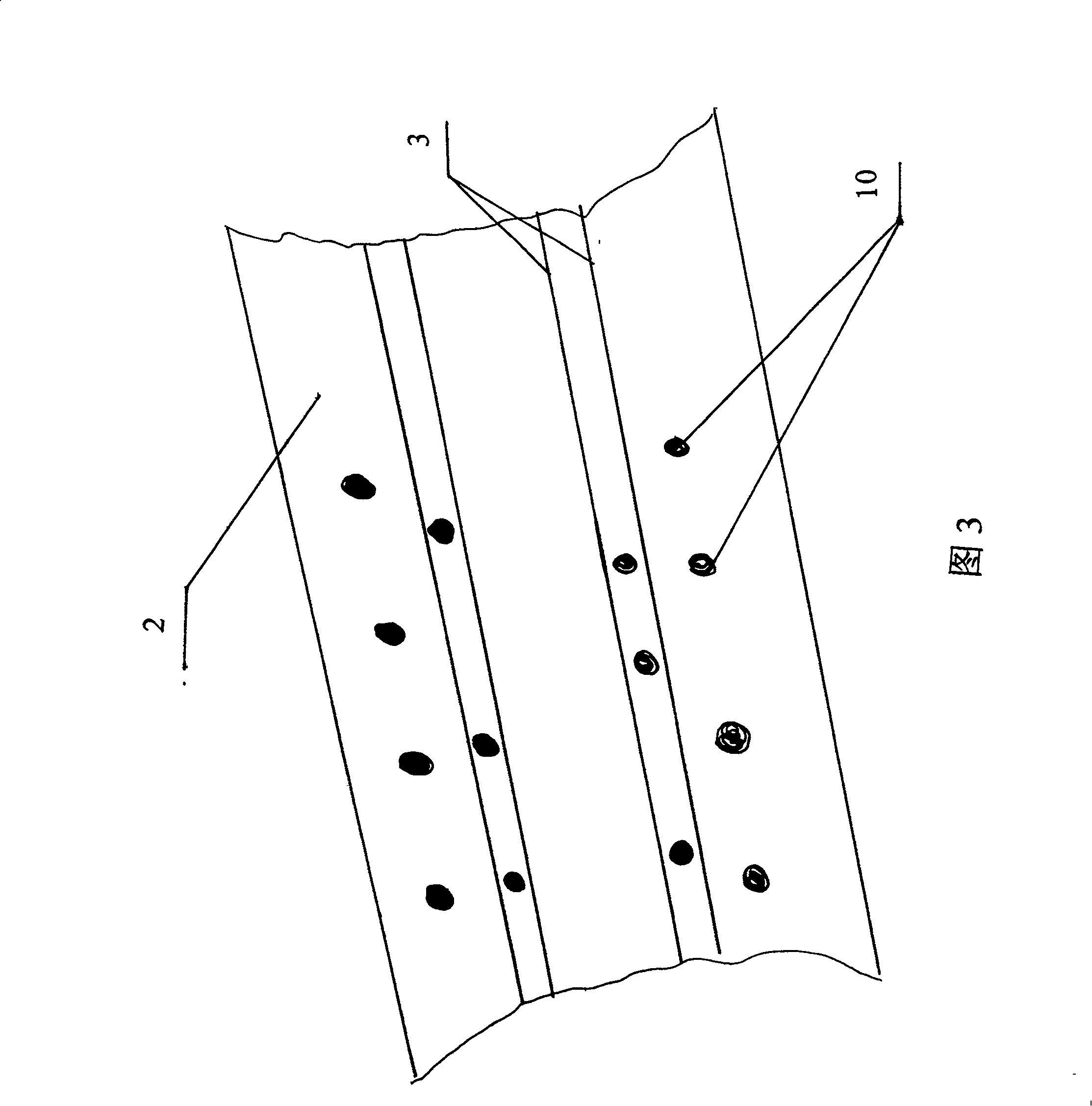

[0017] There can be a plurality of docking piers 9 on the dock floor 1 of the dock chamber 6 and on the dock floor 1 of the rear dock chamber 7 . There can be multiple docks 10 on the ground slipway 2 .

[0018] The dock floor 1 can be a curved surface, and the angle β between the dock floor 1 and the horizontal plane can be varied in the range of 0 to 6 degrees, or 0.1 to 3 degrees. Generally, the angle β between the dock floor 1 and the horizontal plane is 0.2 It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com