Treatment method for ash water of heating and power plant

A thermal power plant and water treatment technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high operating costs, achieve low investment and operating costs, be beneficial to environmental protection, and save energy and water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the invention:

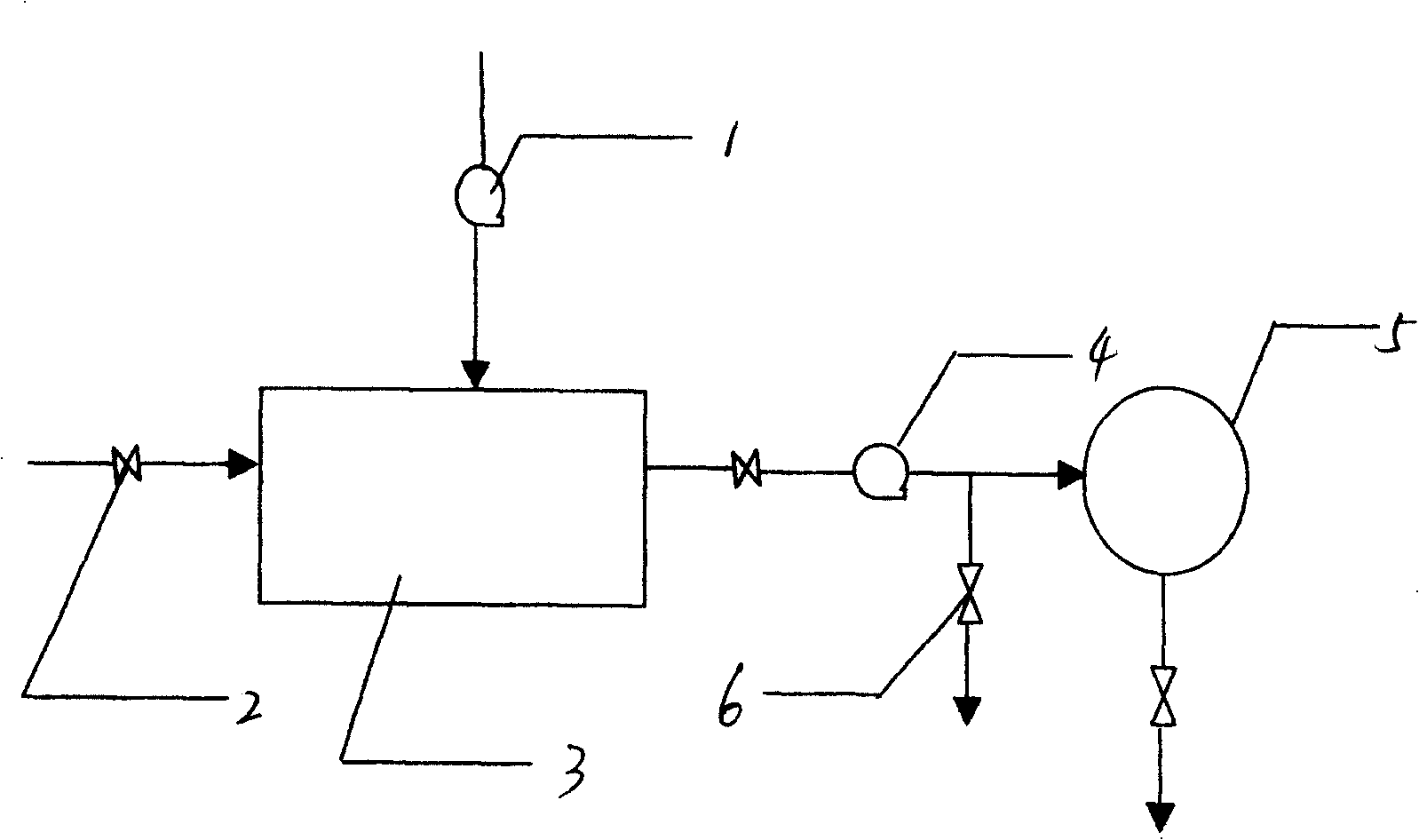

[0017] In the process of alumina production, a large amount of red mud waste will be produced, which is usually transported and stored by wet method. After a period of storage, the solid and liquid will be separated, and the upper clarified water will be red mud return water, which will be used as ash water in thermal power plants. deal with. When treating the ash and slag water of thermal power plants, the ash and slag water containing a large amount of suspended matter should first enter the primary sedimentation tank to settle, reduce the suspended matter in the effluent to less than 5000 mg / l, and enter the water intake tank 3 through the valve 2, and return the red mud to the water Use the red mud return water pump 1 from the top of the water intake tank 3 to pump in, and the amount added is calculated in parts by weight. Add 2 to 8 parts of red mud return water for every 100 parts of ash water for control, and the suction force of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com