Method for preparing chemical crosslink gel lattice polymer electrolyte

A gel network and chemical cross-linking technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve the problems of hindering gel formation, low photoelectric conversion efficiency of dye-sensitized solar cells, etc., to achieve enhanced compatibility, high photoelectricity The effect of conversion efficiency and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

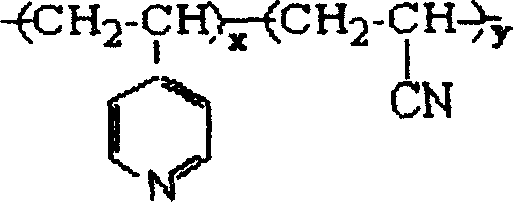

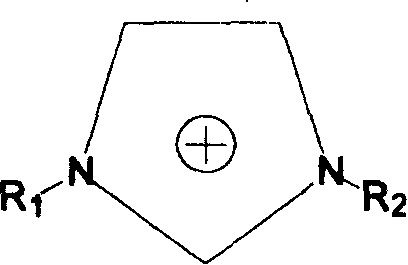

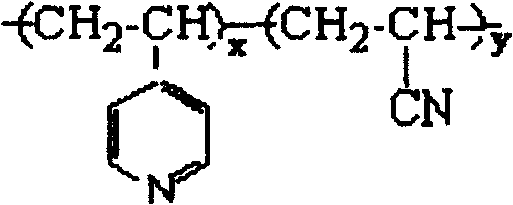

[0034] Add 0.0648g of potassium iodide and 0.0099g of iodine into 1.0000g of propylene carbonate to make a liquid electrolyte. First add 0.0300g of polymer copolymer of 4-vinylpyridine and acrylonitrile, then add 0.0150g of diiodohexane after dissolving, stir evenly, and apply on the dye-sensitized TiO 2 The electrode surface of the nanocrystalline porous film is assembled into a battery by pressing the counter electrode of a Pt sheet on it, and then placed in a 75°C oven for heating and curing for 2 hours to obtain the on-site chemical crosslinked gel network polymer electrolyte of the present invention. Dye-sensitized TiO 2 Nanocrystalline thin film batteries.

Embodiment 2

[0036] Except changing 1.0000g propylene carbonate in step (1) into a mixture of 1.0000g ethylene carbonate and propylene carbonate (volume ratio is 5: 5), other steps and process conditions are the same as in Example 1, to obtain the present invention Dye-sensitized TiO assembled from in-situ chemically cross-linked gel network polymer electrolyte 2 Nanocrystalline thin film batteries.

Embodiment 3

[0038] Except that the Pt sheet counter electrode in step (4) is changed to a platinum-loaded counter electrode, other steps and process conditions are the same as in Example 2, and the dye assembled from the on-site chemical cross-linked gel network polymer electrolyte of the present invention is obtained. Sensitized TiO 2 Nanocrystalline thin film batteries.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap