Protective cover for constant-velocity universal joint

A technology of constant velocity universal joint and protective cover, which is applied in the field of protective cover and can solve problems such as biting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

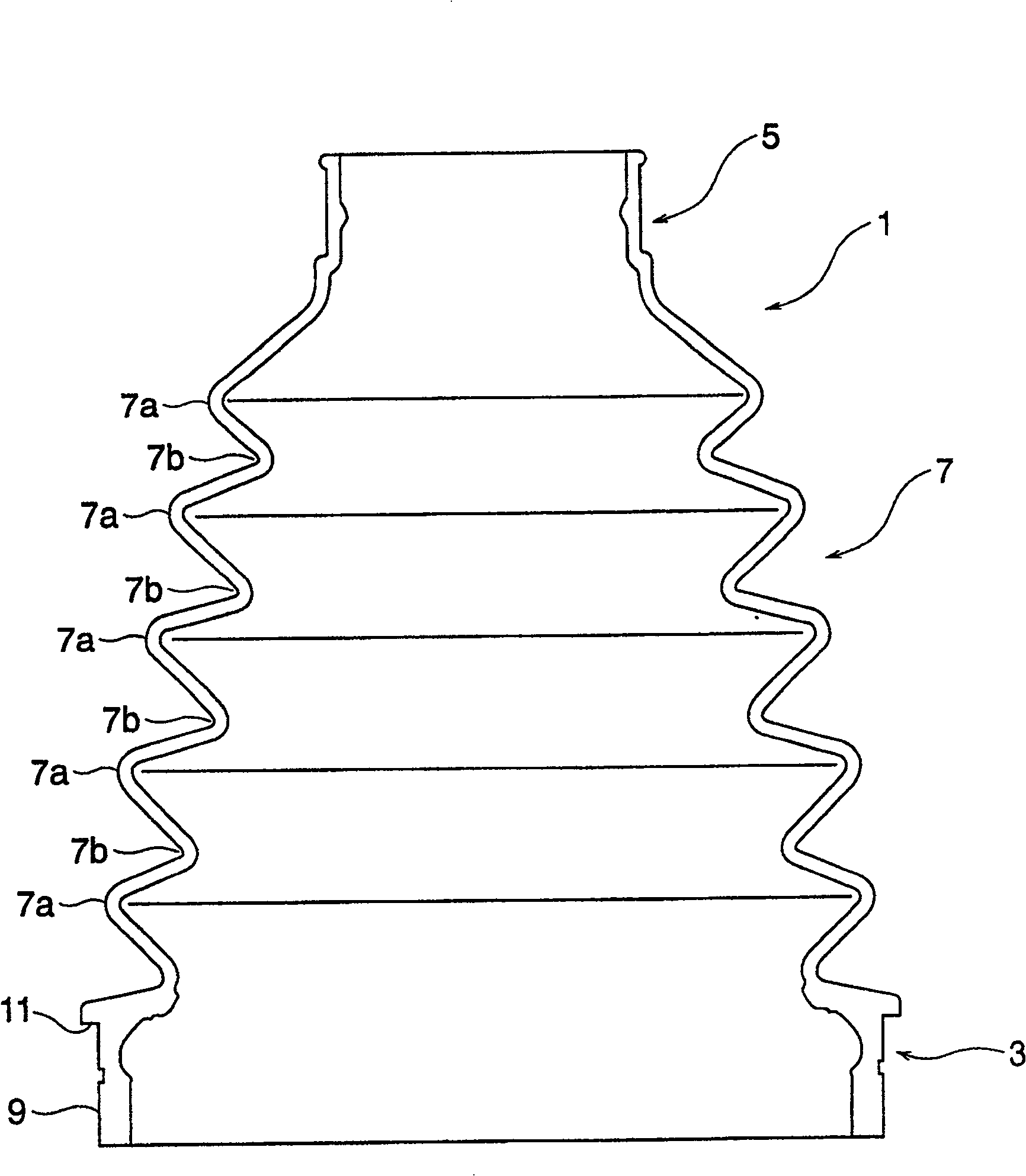

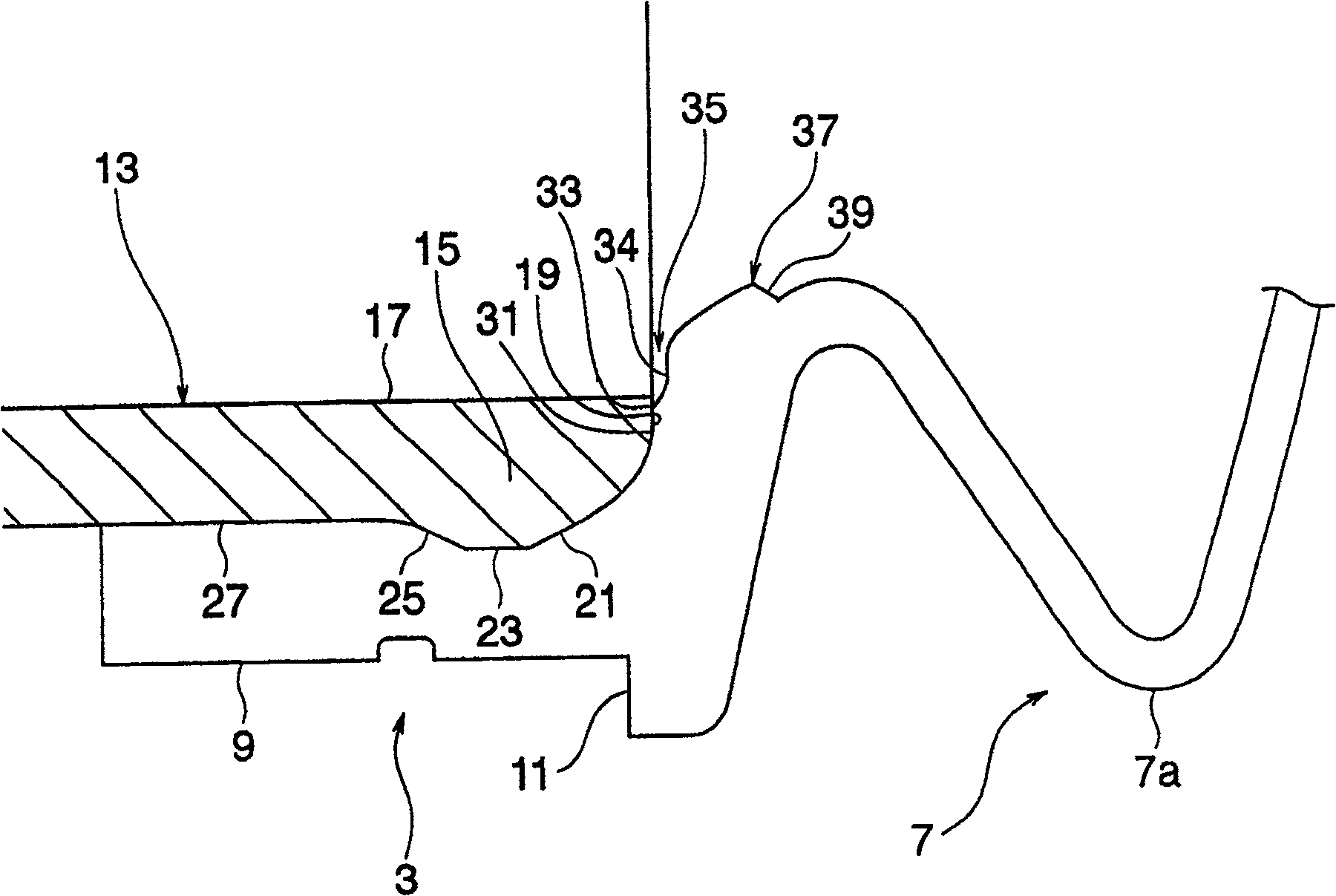

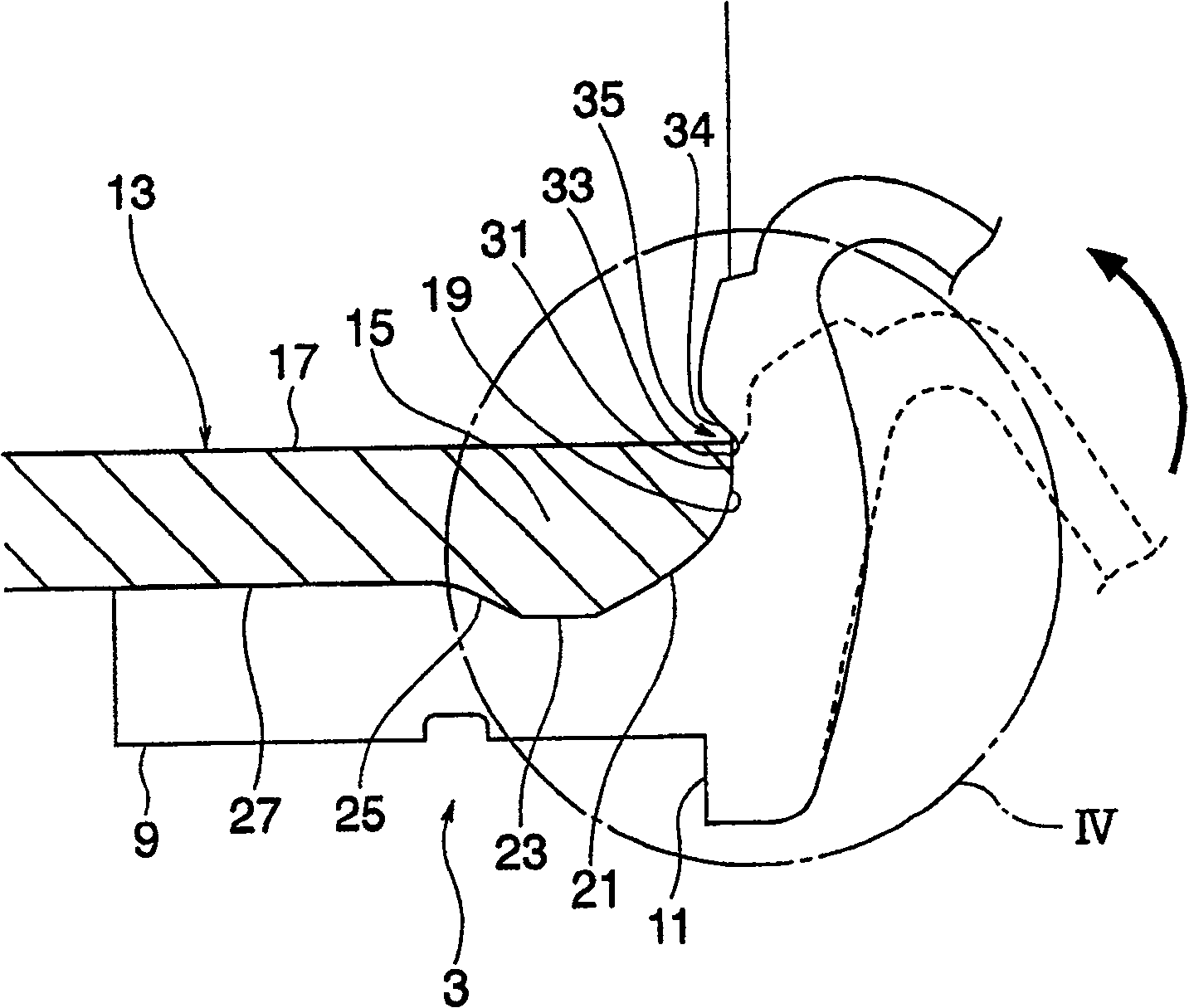

[0013] An embodiment of a protective cover for a constant velocity joint applied to the present invention will be described below. figure 1 A front view showing an appearance of a boot for a constant velocity joint according to an embodiment of the present invention. Such as figure 1 As shown in , the protective cover 1 is made cylindrical and has a large end portion 3 fixed to the side of the constant velocity joint, and a shaft fixed to the drive shaft connected to the constant velocity joint. The small end part 5 of the side. Furthermore, a flexible and structurally bendable bellows 7 is formed between the large end portion 3 and the small end portion 5 . It should be noted that in the embodiment of the present invention, the protective cover 1 is formed of a resin having elasticity, such as a thermoplastic polyester-based elastomer.

[0014] The bellows 7 is composed of repeatedly arranged convex portions 7a and concave portions 7b extending circumferentially in the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com