Debubbling and drying apparatus for dipping insulative media of power capacitors

A technology of power capacitors and insulating mediums, applied in the direction of fixed capacitor dielectrics, capacitors, capacitor manufacturing, etc., can solve problems such as unsatisfactory heat dissipation effect and affect the stability of power capacitors, avoid internal corrosion and expansion, and improve thermal stability. and service life, high temperature and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

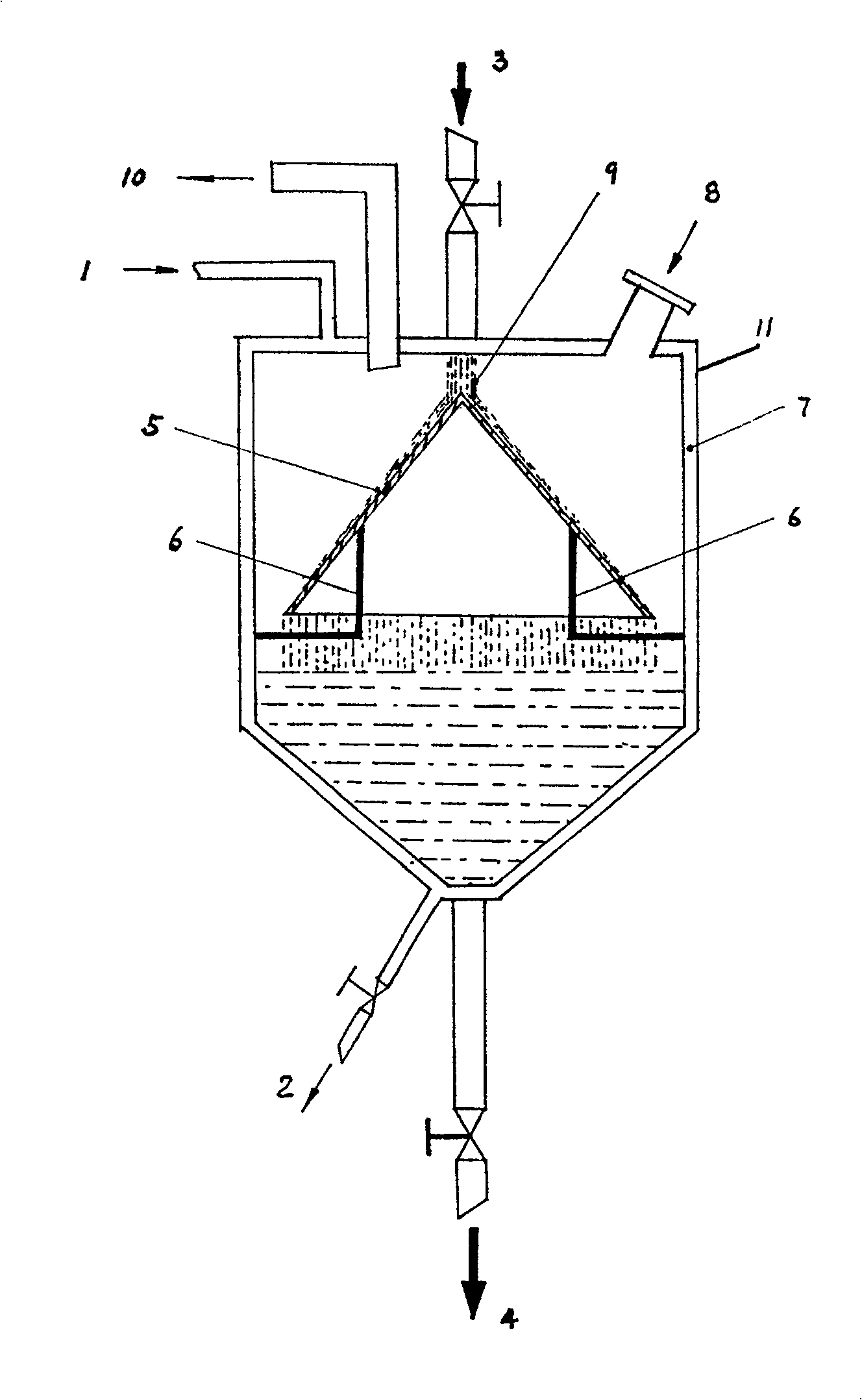

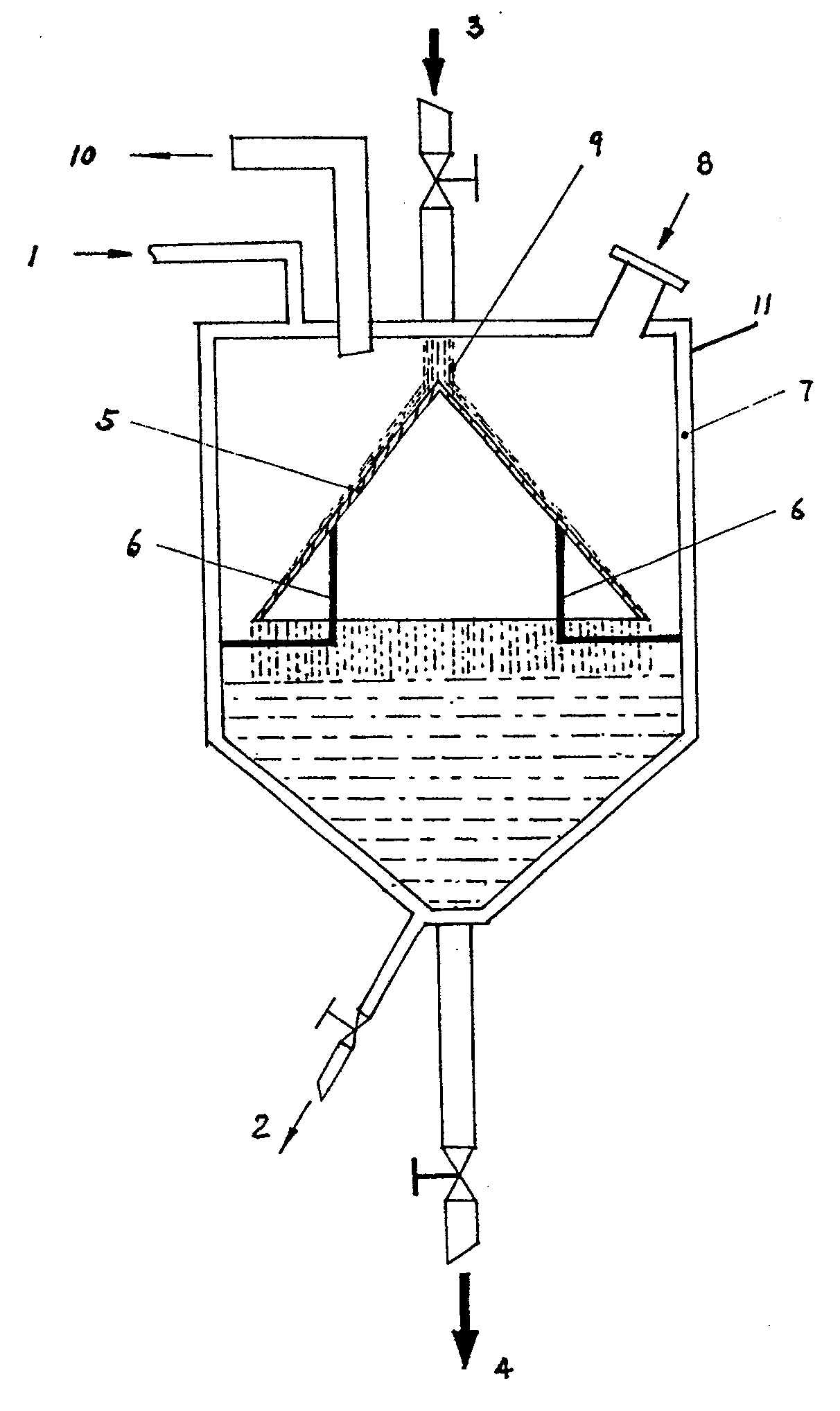

[0015] The electrical grade polypropylene film coated with a layer of aluminum film on one side is used as the electrode material, and the polybutene emulsion with an average molecular weight ≈ 1000 is used as the impregnated insulating medium to make a power capacitor. Electrode rolling, insulating medium filling, sealing, vacuuming and other processes in the power capacitor shell are as usual; it is only because of the trace moisture and air bubbles contained in the polybutene emulsion that it is difficult to use a vacuum pump after sealing. Therefore, before the polybutene emulsion is filled and filled, it is processed on the negative pressure defoaming and drying device provided by the present invention, and the temperature of the hot water used for defoaming and drying is controlled at 85°C.

Embodiment 2

[0017] As shown in the accompanying drawings, the casing 11 and the umbrella-shaped defoaming mechanism 5 of the defoaming drying device provided by the present invention are made of stainless steel, and the casing 11 is provided with a spacer 7, which can pass hot water or steam, and can also use electric heating. The umbrella-shaped defoaming mechanism is welded and fixed with four supporting frames 6 and the inner wall of the casing 11. The outer side of the box body 11 can be covered with heat insulating material.

[0018] The properties of polyisobutylene emulsion are similar to those of polybutene emulsion, and the examples are omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com