High lossing energy composite magnetorheopectic damping device

A kind of magnetorheological damper, damper technology, applied in building components, anti-vibration and other directions, can solve the problem of magnetorheological body sealing Limited rigidity and other problems, to achieve excellent shock absorption, simple structure, and reduce the effect of earthquake response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

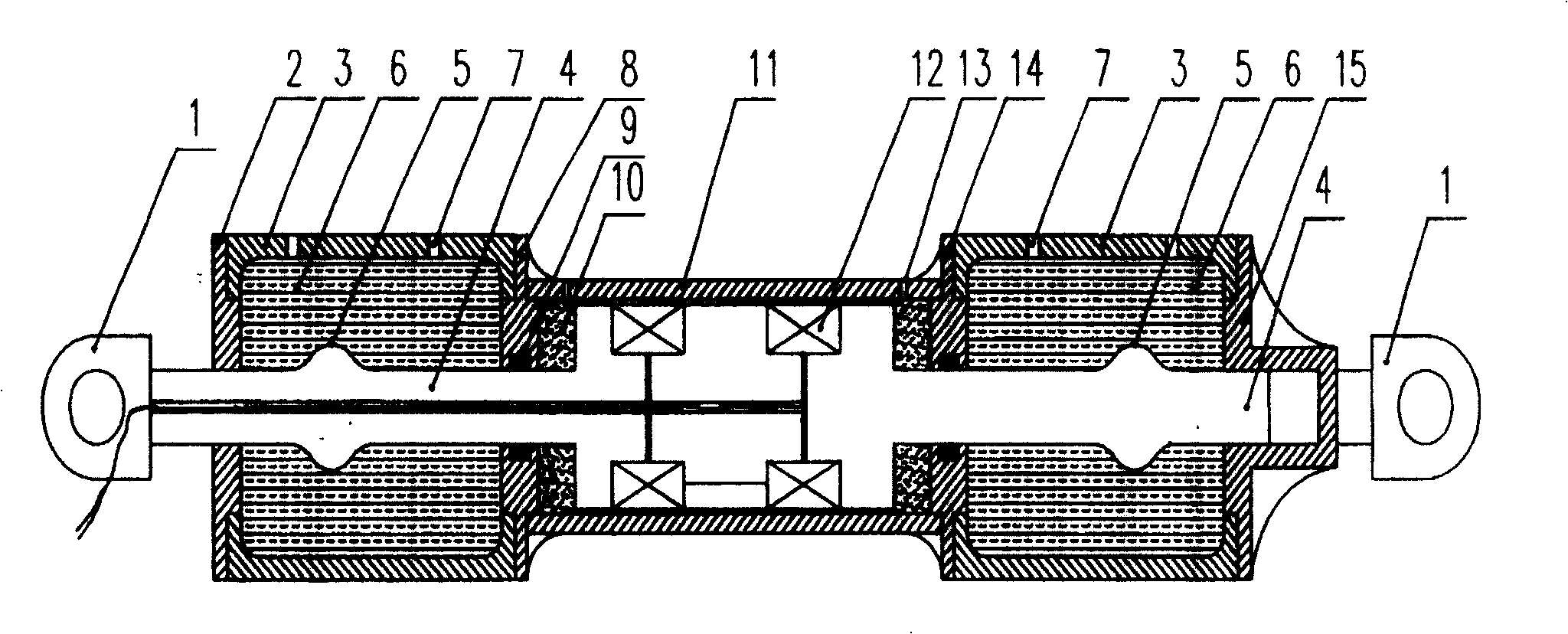

[0015] The high energy consumption composite magnetorheological damper of the invention is composed of a magnetorheological damper part and a lead damper part. The magnetorheological damper part is composed of magnetorheological damper working cylinder 11, magnetorheological damper front sealing baffle 8, magnetorheological damper rear sealing baffle 14, sealing ring 9, magnetorheological body 10, electromagnetic screw Wire pipe 12, injection hole 13 and other parts. The lead damper part is mainly composed of the lead damper working cylinder 3, the piston connecting rod 4, the piston connecting rod protrusion 5, the lead 6, the lead injection hole 7 and the sealing plates at both ends. The front sealing baffle 8 of the magnetorheological damper and the rear sealing baffle 14 of the magnetorheological damper firmly connect the working cylinder 3 of the lead damper and the working cylinder 11 of the magnetorheological damper into a whole, which not only makes the magnetorheologi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com