Solar cell module-mounting structure and solar cell module array

A solar cell and installation structure technology, applied in the directions of solar thermal energy, solar thermal power generation, photovoltaic module support structure, etc., to achieve the effect of reducing cost, improving reliability and avoiding disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

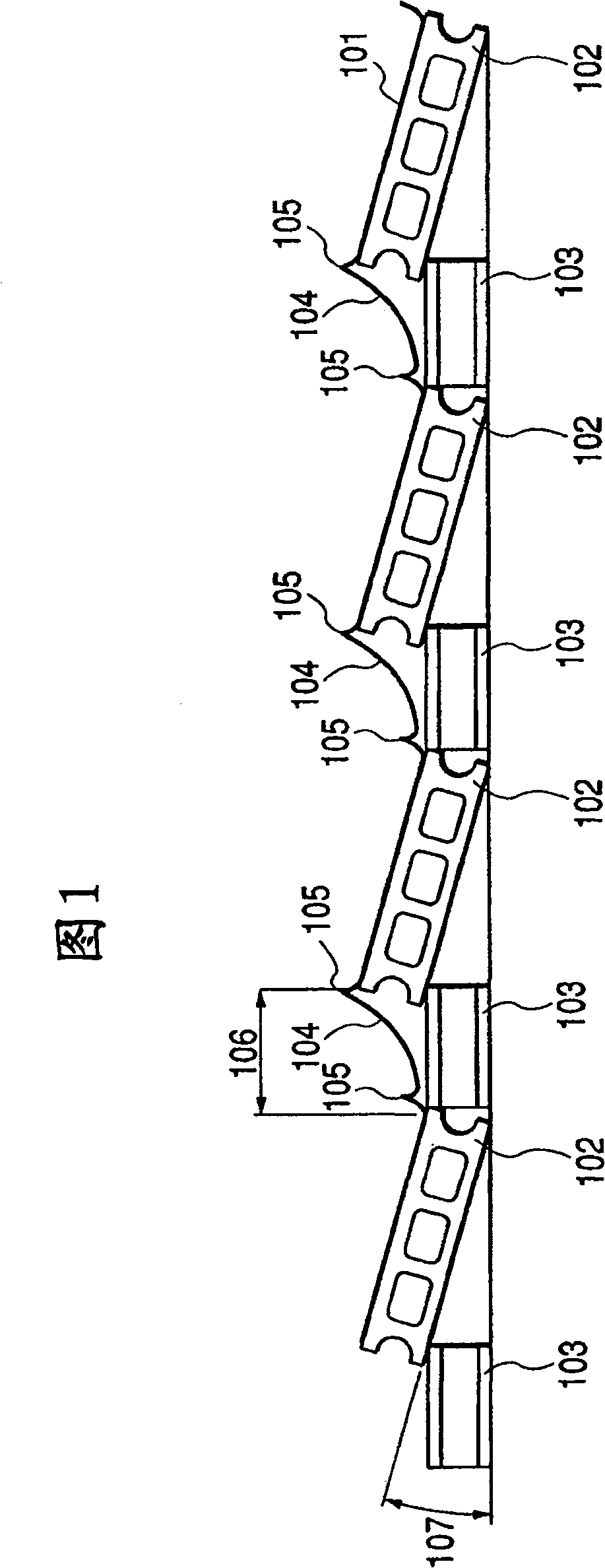

[0093] 10 and 11 are schematic diagrams showing the solar cell module mounting structure of the present invention. Fig. 10 is a view of the mounting structure viewed from the side. Fig. 11 is a view of a part of the mounting structure viewed from the light receiving surface of the solar cell module.

[0094] 10 and 11, reference numeral 1001 indicates the solar cell module; 1002 indicates the first row of plate-shaped members; 1003 indicates the first row of support members; 1008 indicates the second row of plate-shaped members; 1009 indicates the second row of support members; 1010 indicates 1011 indicates the third row of supports; 1012 indicates the fourth row of plates; 1013 indicates the fourth row of supports; 1004 indicates connecting cables; 1005 indicates the ring sleeve; 1006 indicates the inclination angle of the plates ; 1007 indicates the distance between the brackets; 1016 indicates the parallel connecting cables; 1017 indicates the series connection direction o...

example 2

[0124] In this example, the inclination angle of the plate, the distance between the brackets (the direction of the support), and the structure of the solar cell module are different from the solar cell module installation structure in Example 1.

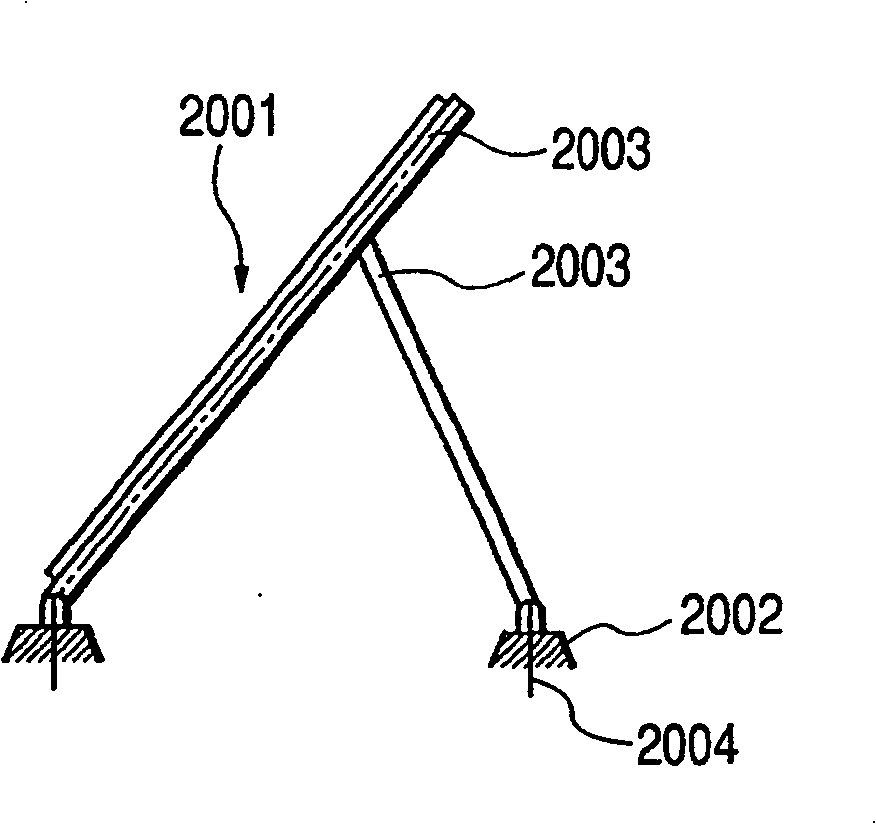

[0125] Fig. 13 is a side view of the solar cell module of this example. In Fig. 13, reference numeral 1201 indicates a solar cell module; 1202 indicates a plate-shaped piece; 1203 indicates a support; 1204 indicates a connecting cable; 1205 indicates a connecting piece (annular sleeve); 1206 indicates the distance between brackets; The angle of inclination of the piece.

[0126] (solar battery module)

[0127] Figure 14A and 14B is a schematic diagram of the solar cell module used in this example. Figure 14A is the plan view of the solar cell module, Figure 14B is along Figure 14A The cross-sectional view made at line 14B-14B.

[0128] The solar cell module 1301 has a semiconductor photosensitive layer 1307, which is also...

example 3

[0154] In this example, the surface on which the panel is mounted is a concrete surface. Fig. 15 is a side view of the solar cell module of this example. In FIG. 15 , reference numeral 1401 indicates a solar cell module; 1402 indicates a plate-shaped member; 1403 indicates a supporting member; 1404 indicates a connecting cable; 1405 indicates a connecting piece (annular sleeve); 1406 indicates the distance between brackets; 1408 indicates an insulating member; 1409 indicates a concrete surface as a plate-shaped member installation surface.

[0155] In this example, the rubber 1408 is a 5mm thick, 50mm wide insulating piece placed between the side 1410 of the plate 1402 that will be in contact with the concrete surface 1409 and the concrete surface 1409, and between the support 1403 and the concrete surface 1409, In addition to the conditions described in Example 1, to further reduce the leakage current to the uninsulated cables and the concrete surface 1409 of the solar cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com