Double layer hardness pen cap production method

A production method and pen cover technology, applied in the field of pen cover production and stationery production, can solve problems such as hand fatigue and tenderness, finger deformation, finger damage, etc., and achieve the effects of wide application, rich flexibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

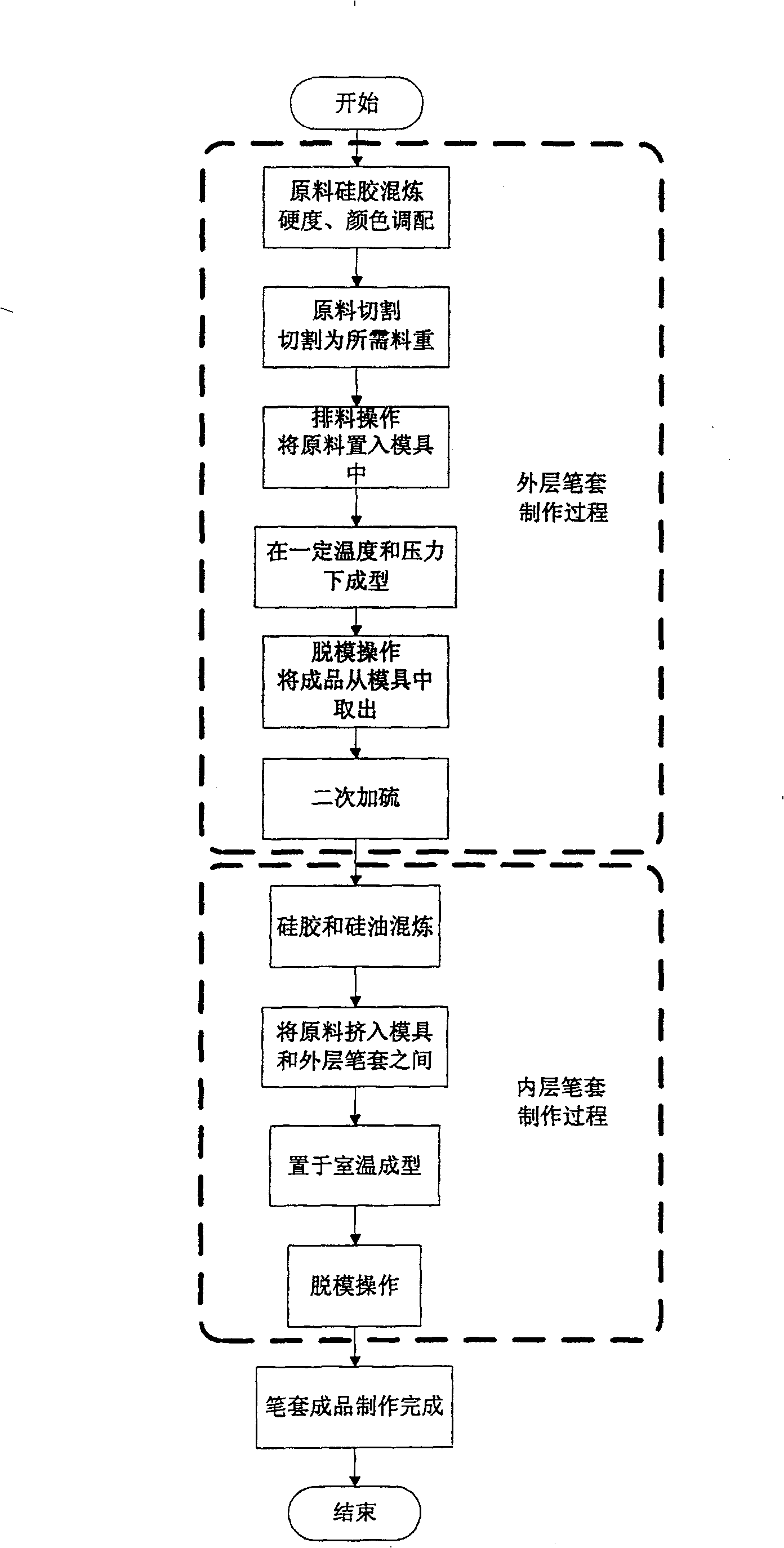

Method used

Image

Examples

Embodiment 1

[0037] Material of outer pen case: silicone rubber 30 shore A

[0038] First, make the outer pen case:

[0039] (1) Mix silicone rubber 30 shore A, and adjust the corresponding color and hardness index;

[0040] (2) According to the required material weight, the silicone rubber 30 shore A after mixing is cut;

[0041] (3) Put the cut silicone rubber 30 shore A into the corresponding mold;

[0042] (4) Put the silicone rubber 30 shore A in the mold at a temperature of 150°C and a pressure of 7.84×10 6 Pa(80kg / cm 2 ) for 200 seconds;

[0043] (5) Take out the finished product after molding from the mould;

[0044] (6) Carry out secondary vulcanization treatment to the finished product, thereby obtain the finished product of the outer layer pen cover.

[0045] Material of inner pen case:

[0046] Chongyue 13 series

100g:10g

160g

[0047] Then, make the inner pen cover:

[0048] (1) Mixing the above-mentioned silica gel raw ma...

Embodiment 2

[0053] Material of outer pen case: silicone rubber 30 shore A

[0054] First, make the outer pen case:

[0055] (1) Mix silicone rubber 30 shore A, and adjust the corresponding color and hardness index;

[0056] (2) According to the required material weight, the silicone rubber 30 shore A after mixing is cut;

[0057] (3) Put the cut siliconerubber 30 shore A into the corresponding mould;

[0058] (4) Put the silicone rubber 30 shore A in the mold at a temperature of 200°C and a pressure of 14.7×10 6 Pa(150kg / cm 2 ) for 300 seconds;

[0059] (5) Take out the finished product after molding from the mould;

[0060] (6) Carry out secondary vulcanization treatment to the finished product, thereby obtain the finished product of the outer layer pen cover.

[0061] Material of inner pen case:

[0062] Chongyue 13 series

100g:10g

160g

[0063] Then, make the inner pen cover:

[0064](1) Mixing the above-mentioned silica gel raw ma...

Embodiment 3

[0069] Material of outer pen case: silicone rubber 30 shore A

[0070] First, make the outer pen case:

[0071] (1) Mix silicone rubber 30 shore A, and adjust the corresponding color and hardness index;

[0072] (2) According to the required material weight, the silicone rubber 30 shore A after mixing is cut;

[0073] (3) Put the cut silicone rubber 30 shore A into the corresponding mold;

[0074] (4) Put the silicone rubber 30 shore A in the mold at a temperature of 175°C and a pressure of 11.27×10 6 Pa(115kg / cm 2 ) for 250 seconds;

[0075] (5) Take out the finished product after molding from the mould;

[0076] (6) Carry out secondary vulcanization treatment to the finished product, thereby obtain the finished product of the outer layer pen cover.

[0077] Material of inner pen case:

[0078] Chongyue 13 series

100g:10g

160g

[0079] Then, make the inner pen cover:

[0080] (1) Mixing the above-mentioned silica gel raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com