Freezing system with hot-liquid defrosting function

A technology for hot liquid defrosting and freezing systems, which can be used in defrosting, refrigerators, refrigeration components, etc., and can solve problems such as insufficient defrosting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

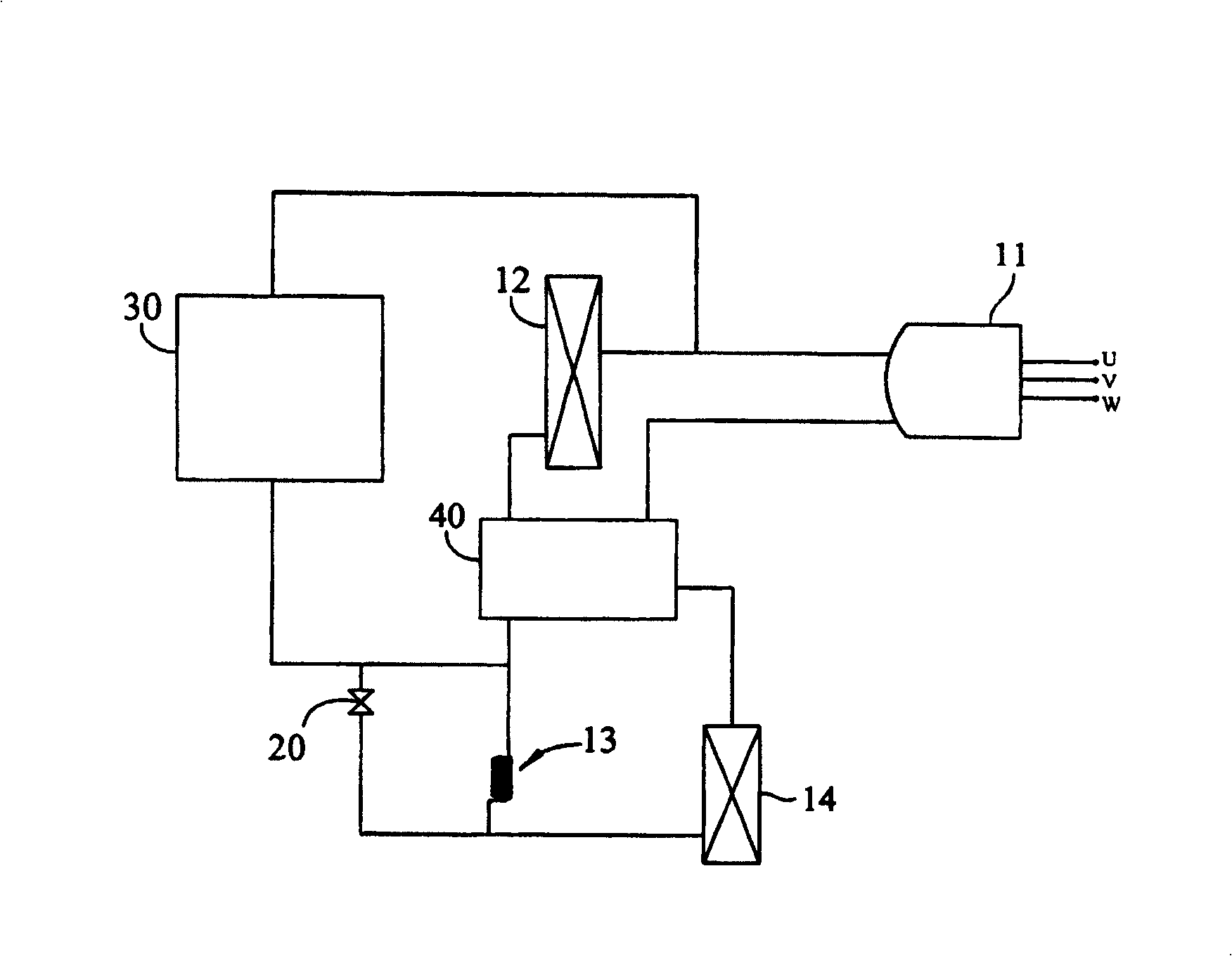

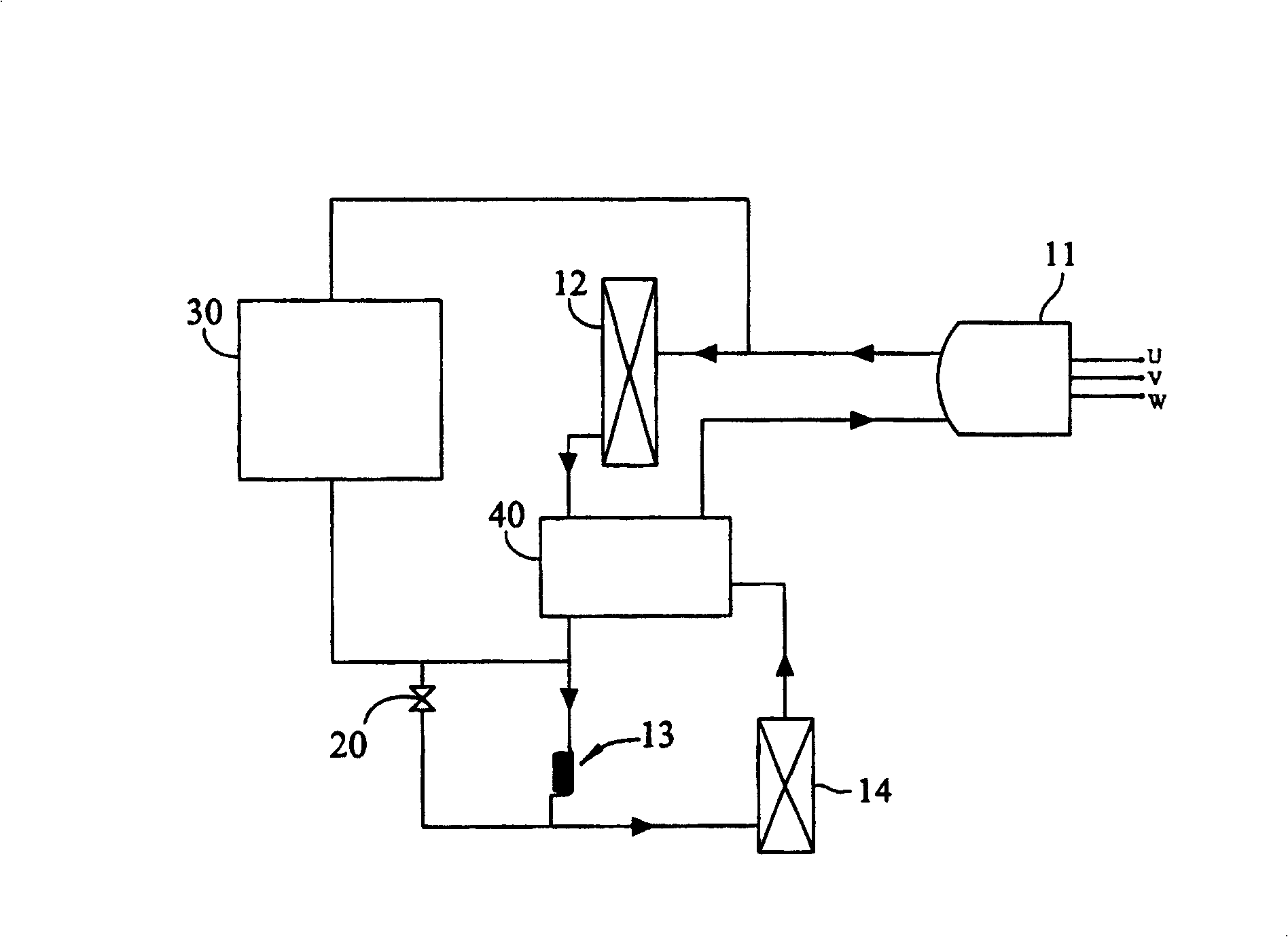

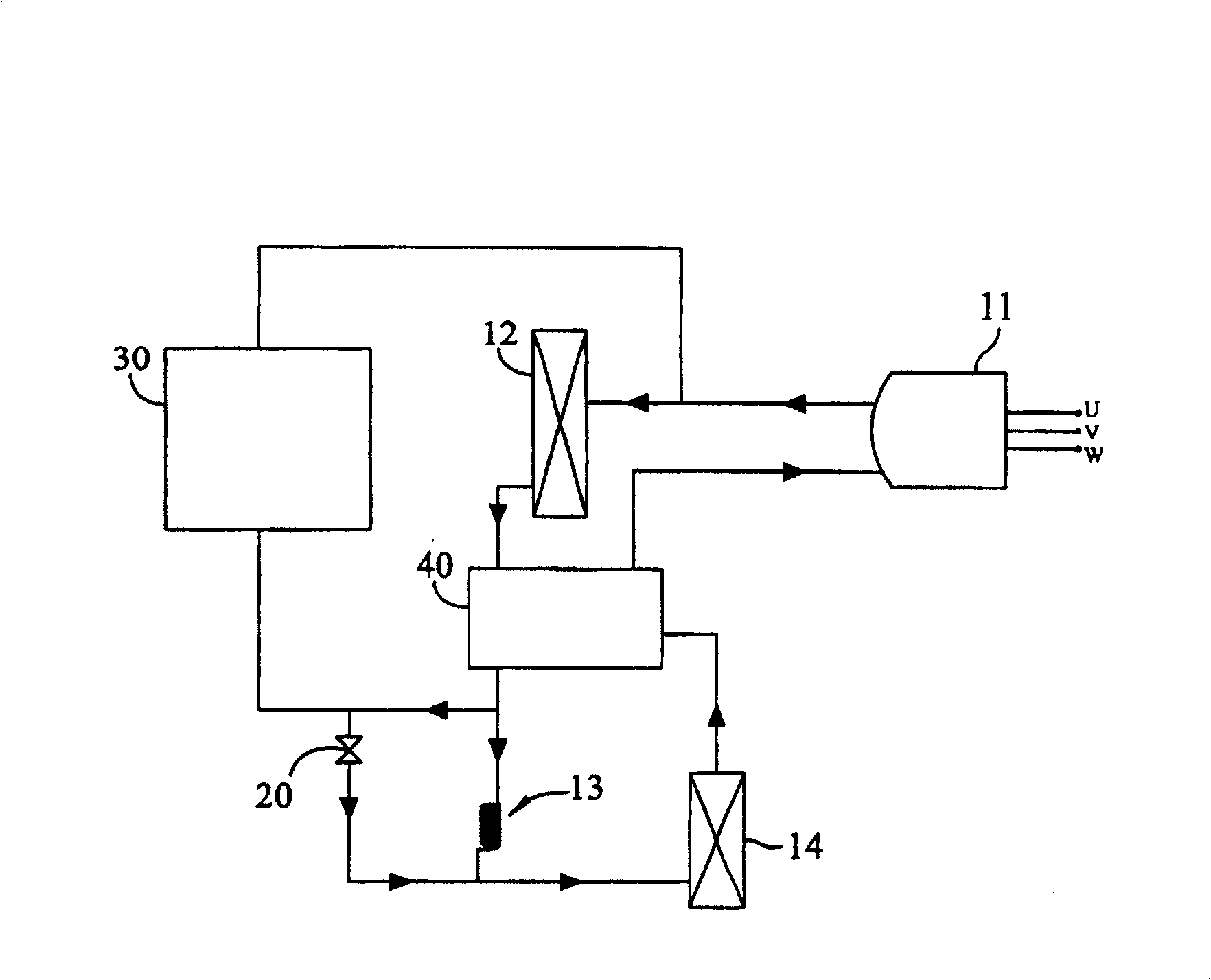

[0024] According to the refrigerating system of hydrothermal defrosting disclosed by the present invention, please refer to " figure 1 ", which includes a compressor 11, a condenser 12, an expansion valve 13, an evaporator 14, a defrosting control valve device 20, a hot liquid defrosting auxiliary device 30 and a superheat adjustment liquid storage module 40, and the outlet of the compressor 11 is connected Between the condenser 12 and the hot liquid defrosting auxiliary device 30, the outlet of the condenser 12 is connected to the superheat adjustment liquid storage module 40, and is connected to the expansion valve 13 and the defrosting control valve device 20, and both are connected to the evaporator 14, and is connected to the compressor 11 by the hot liquid defrosting auxiliary device 30, and the evaporator 14 is connected to the inlet of the compressor 11 after adjusting the liquid storage module 40 by superheat.

[0025] During normal freeze cycle operation, see " fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com