Aspherical focusing lens

A kind of aspherical surface and lens technology, applied in the field of lenses, can solve problems such as not being able to eliminate aberrations well, achieve the effect of small refractive index error and distortion, and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

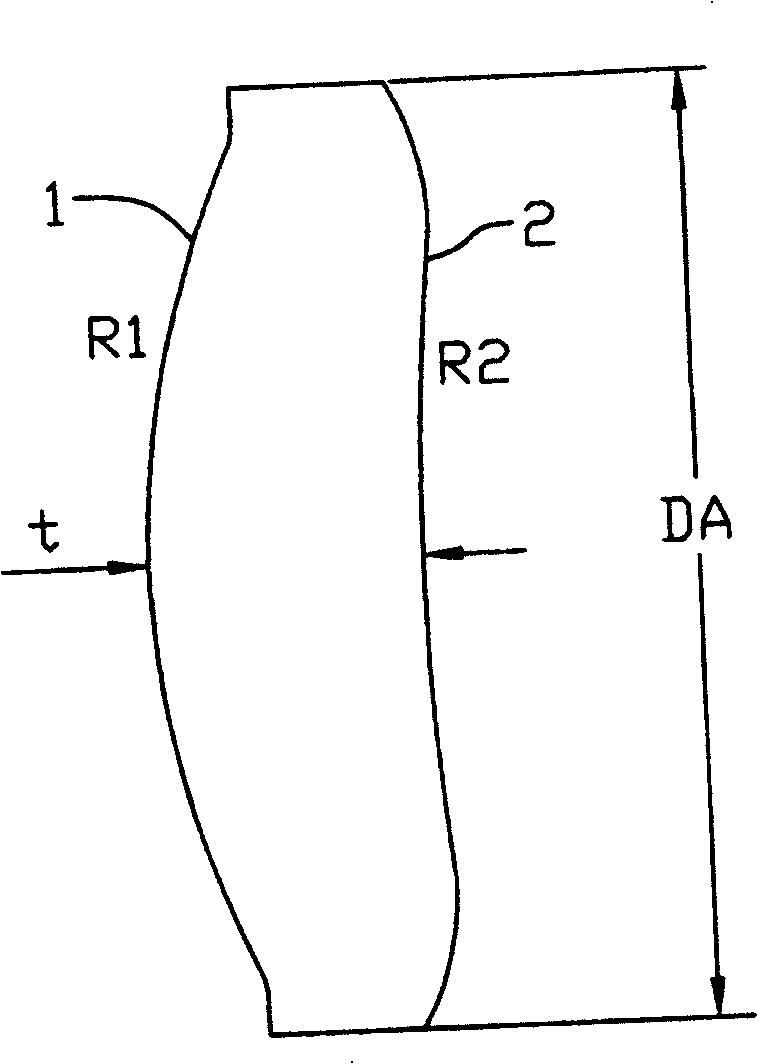

[0048] Such as figure 2 Shown is a schematic diagram of the structure of the aspheric converging lens of the present invention, the aspheric converging lens includes a first aspheric surface 1 and a second aspheric surface 2, and the radius of curvature of the first aspheric surface 1 is R 1 , the radius of curvature of the second aspheric surface 2 is R 2 , the thickness of the center of the lens is t, and the diameter of the lens is DA.

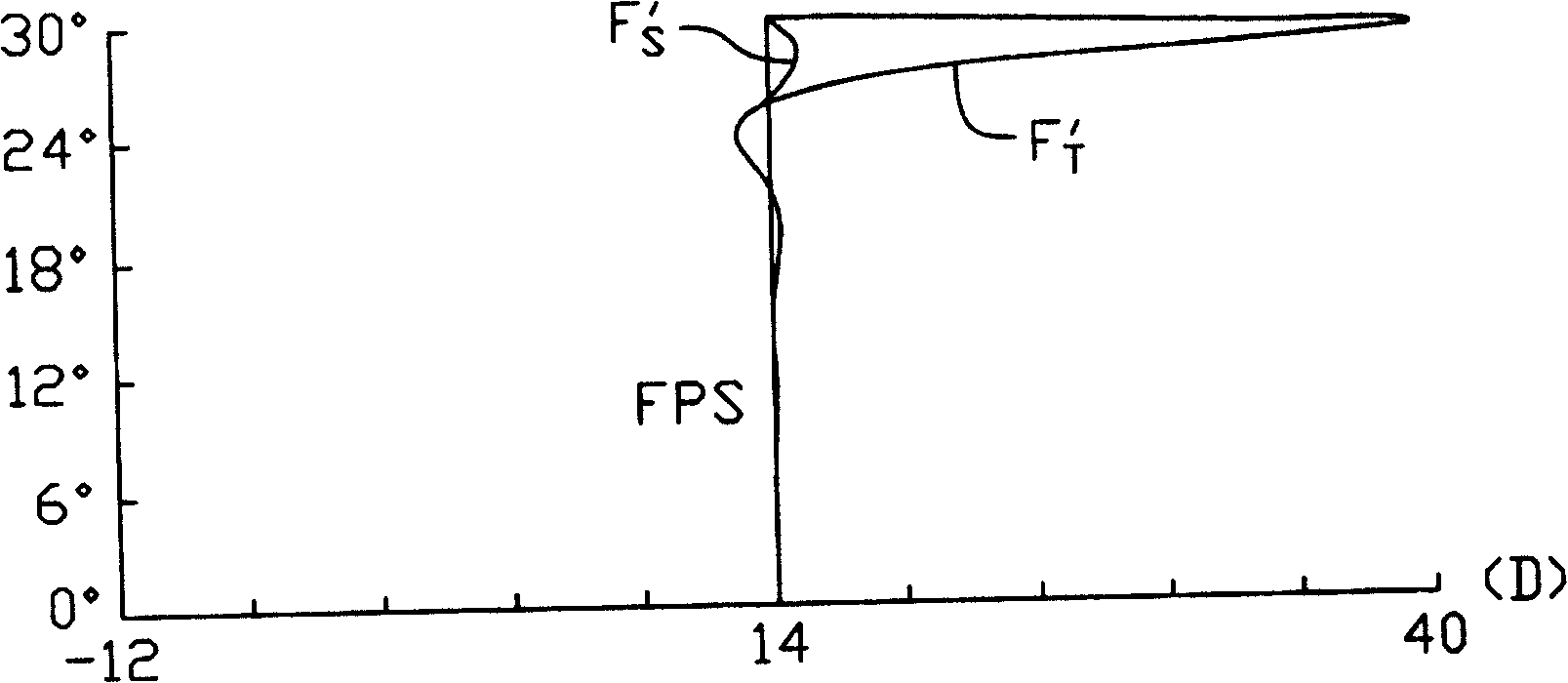

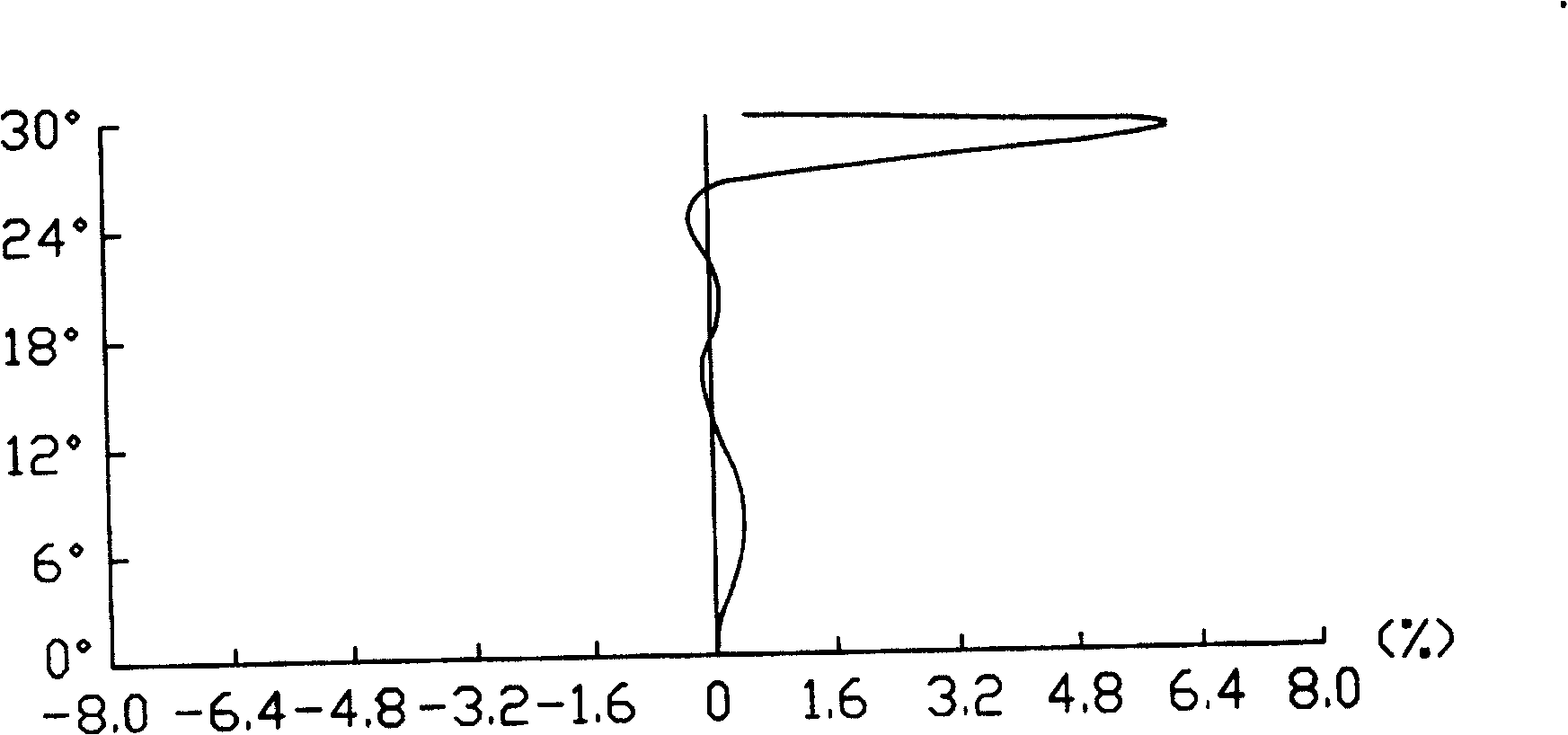

[0049] The aspherical converging lens of the present invention adopts damping least square method to optimize the design. In the performance function (3), the process of correcting the aberration to the target value by the design of the aspheric converging lens of the present invention is expressed as having 10 variable design parameters, that is, 10 design variable performance functions. with x 1 、x 2 、x 3 ,...,x 10 The aspheric surface representing the first aspheric surface 1 is the number P 1 , B 1 、C 1 、D 1 ,E 1 The number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com