Method for preparing Ag sensitized zinc oxide photocatalyst with visible light activity

A technology of silver-sensitized zinc oxide and photocatalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems of poor effect and achieve rapid heating , cost saving, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 1g of zinc acetate in a mixed solution of ethylene glycol and glycerol, wherein the mass ratio of ethylene glycol: glycerol: zinc acetate is 50: 25: 1, and the mixed solution obtained after stirring evenly is heated by microwave circulation. After 5 cycles, the obtained suspension was filtered, washed, dried, and then roasted at 300°C to obtain zinc oxide; 0.2g of zinc oxide and 0.001g of silver nitrate were added to ethylene glycol, wherein ethylene glycol: The mass ratio of silver nitrate: zinc oxide is 50:0.005:1, and the mixed solution obtained after stirring evenly is heated and reduced by microwave circulation, and after 5 cycles; the obtained suspension is filtered and separated, washed with water and absolute ethanol respectively and drying to prepare a silver-sensitized zinc oxide photocatalyst with visible light activity.

Embodiment 2

[0024] Dissolve 1g of zinc acetate in a mixed solution of ethylene glycol and glycerol, wherein the mass ratio of ethylene glycol: glycerol: zinc acetate is 100: 50: 1, and the mixed solution obtained after stirring evenly is heated by microwave circulation. After 10 cycles, the resulting suspension was filtered, washed, dried, and then roasted at 300°C to obtain zinc oxide; 0.2g of zinc oxide and 0.002g of silver nitrate were added to ethylene glycol, wherein ethylene glycol: The mass ratio of silver nitrate: zinc oxide is 100:0.01:1, and the mixed solution obtained after stirring evenly is heated and reduced by microwave circulation, and after 10 cycles; the obtained suspension is filtered and separated, washed with water and absolute ethanol respectively and drying to prepare a silver-sensitized zinc oxide photocatalyst with visible light activity.

Embodiment 3

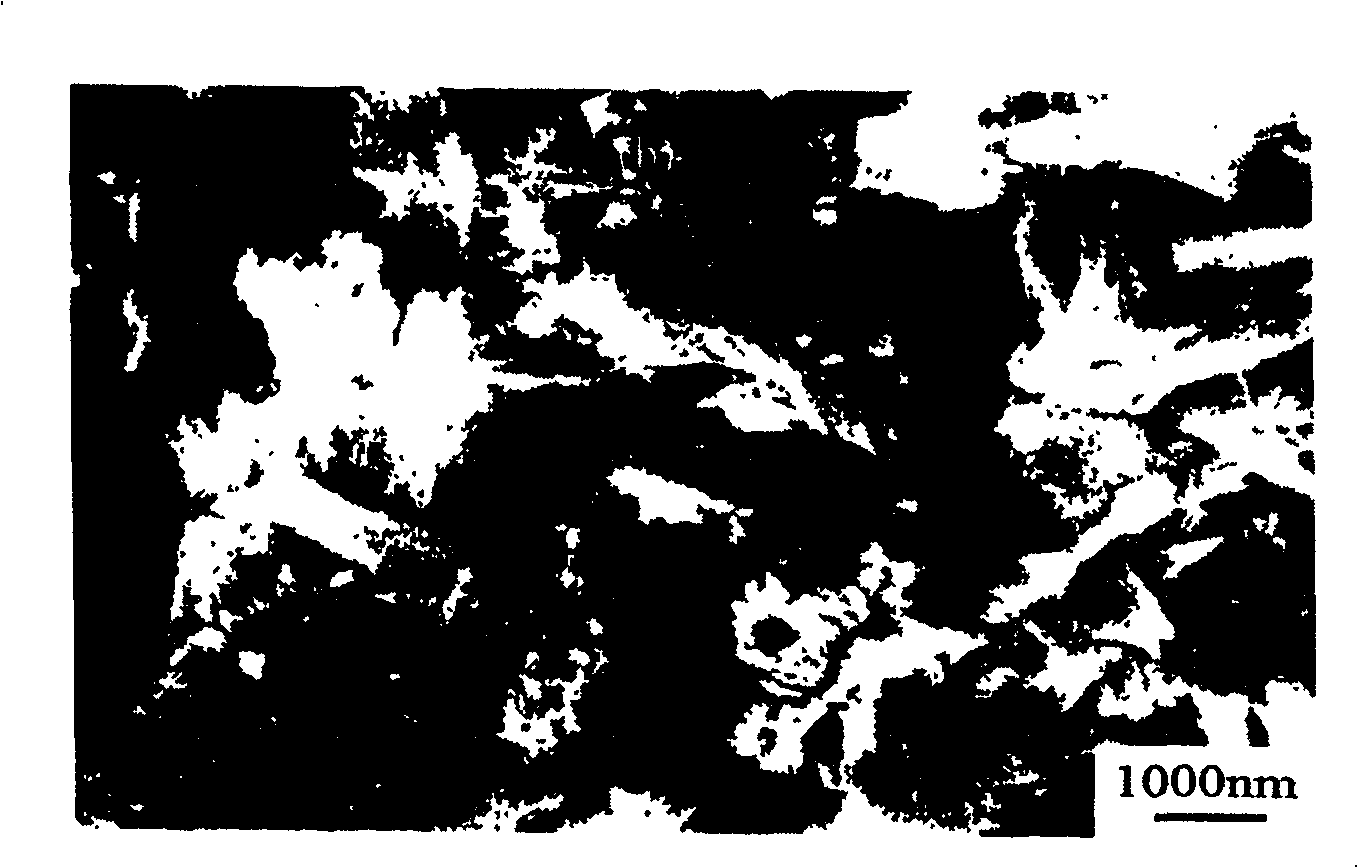

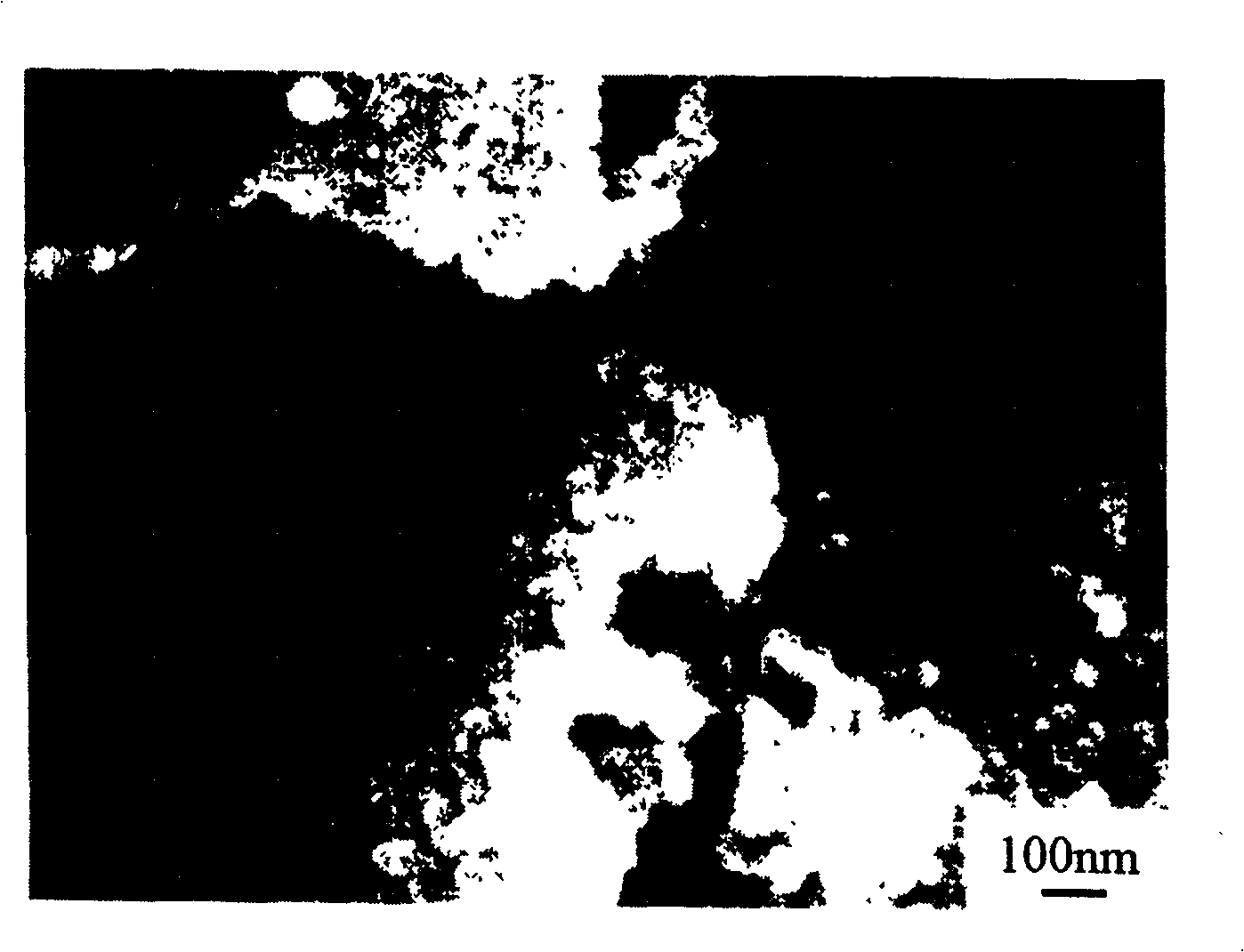

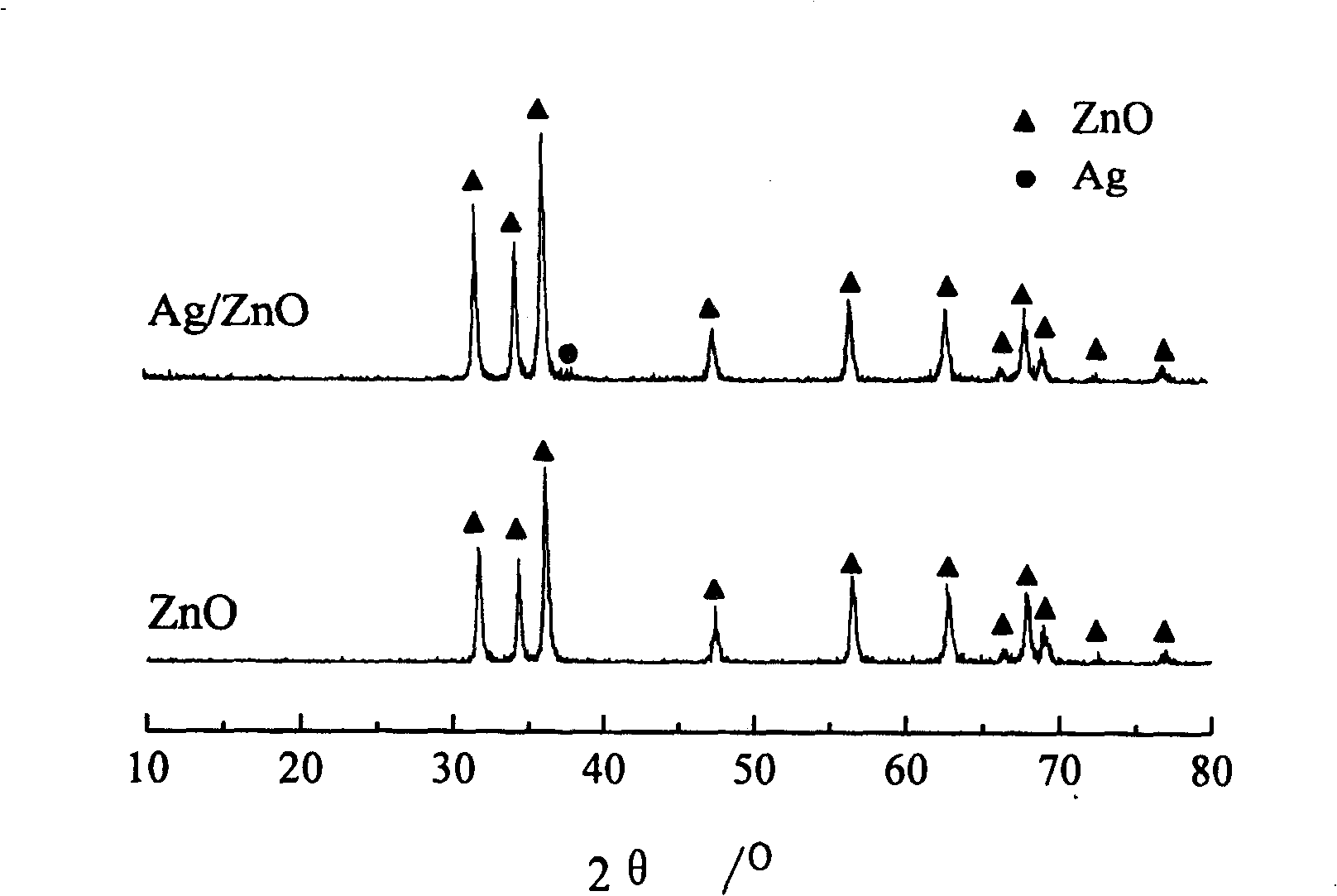

[0026] Dissolve 1g of zinc acetate in a mixed solution of ethylene glycol and glycerol, wherein the mass ratio of ethylene glycol: glycerol: zinc acetate is 150: 80: 1, and the mixed solution obtained after stirring is heated by microwave circulation. After 15 cycles, the obtained suspension was filtered, washed, dried, and then roasted at 400°C to obtain zinc oxide; 0.2g of zinc oxide and 0.004g of silver nitrate were added to ethylene glycol, wherein ethylene glycol: The mass ratio of silver nitrate: zinc oxide is 150:0.02:1, and the mixed solution obtained after stirring evenly is heated and reduced by microwave circulation, and after 10 cycles; the obtained suspension is filtered and separated, washed with water and absolute ethanol respectively , dried, prepared as Figure 1a , Figure 1b with figure 2 The shown silver-sensitized ZnO photocatalyst with visible light activity. in, Figure 1a Explain that the prepared zinc oxide is a particle of 30-50nm, Figure 1b It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com