Cigarette packing box brand printing method

A packaging box and trademark technology, which is applied to the printing of cigarette packaging boxes, the trademark printing of cigarette packaging boxes, and the field of offset printing, can solve problems such as the influence of subjective randomness of operators, and achieve the purpose of preventing subjective randomness and improving production efficiency. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

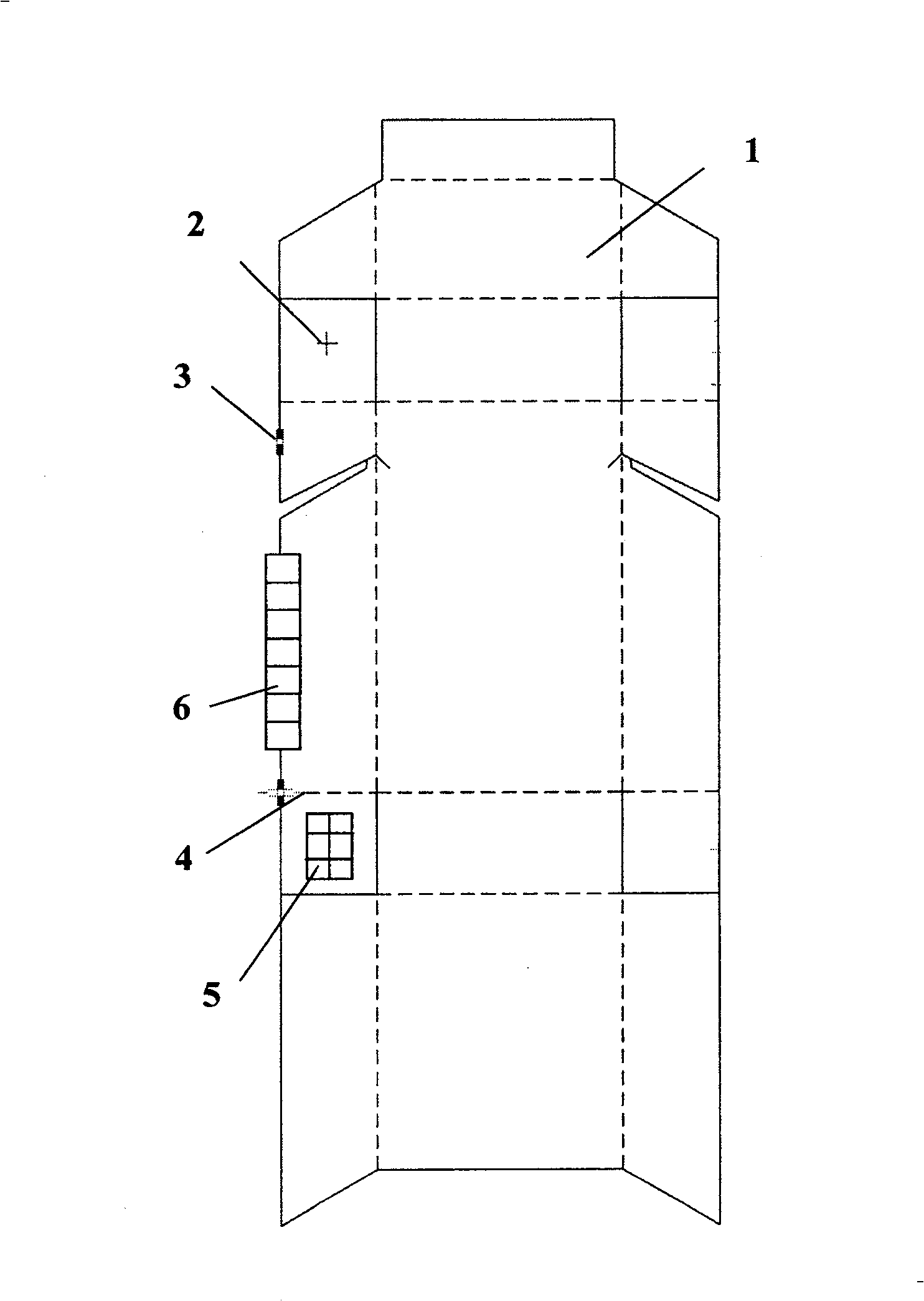

[0010] Such as figure 1 As shown, the trademark printing method for cigarette packaging boxes of the present invention includes a process of printing a trademark pattern on the raw paper 1 using offset printing technology, and the process includes at least one printing on the raw paper 1 with a first color The pattern step, wherein, before the process of printing the trademark pattern, use a printing machine to print a control line on the raw paper 1, and the control line is a cross line 2, or a die cutting line 3, or an indentation registration Line 4, or color standard registration line 5.

[0011] Further, before the process of printing the trademark pattern and after printing the control line on the raw paper 1 by the printing machine, the color code 6 is printed on the raw paper 1 by the printing machine.

[0012] Further, the die-cutting line 3 includes a die-cutting creasing registration line.

[0013] Such as figure 1 In a preferred embodiment of the invention shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com