Core kernel modeling method for micro inertial sensor device and core kernel base

A technology of inertial sensor and modeling method, which is applied in the design field of micro-electromechanical systems, can solve the problems of reusable core modeling without relevant literature reports, inconvenient integration of mixed-signal simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described now in conjunction with accompanying drawing:

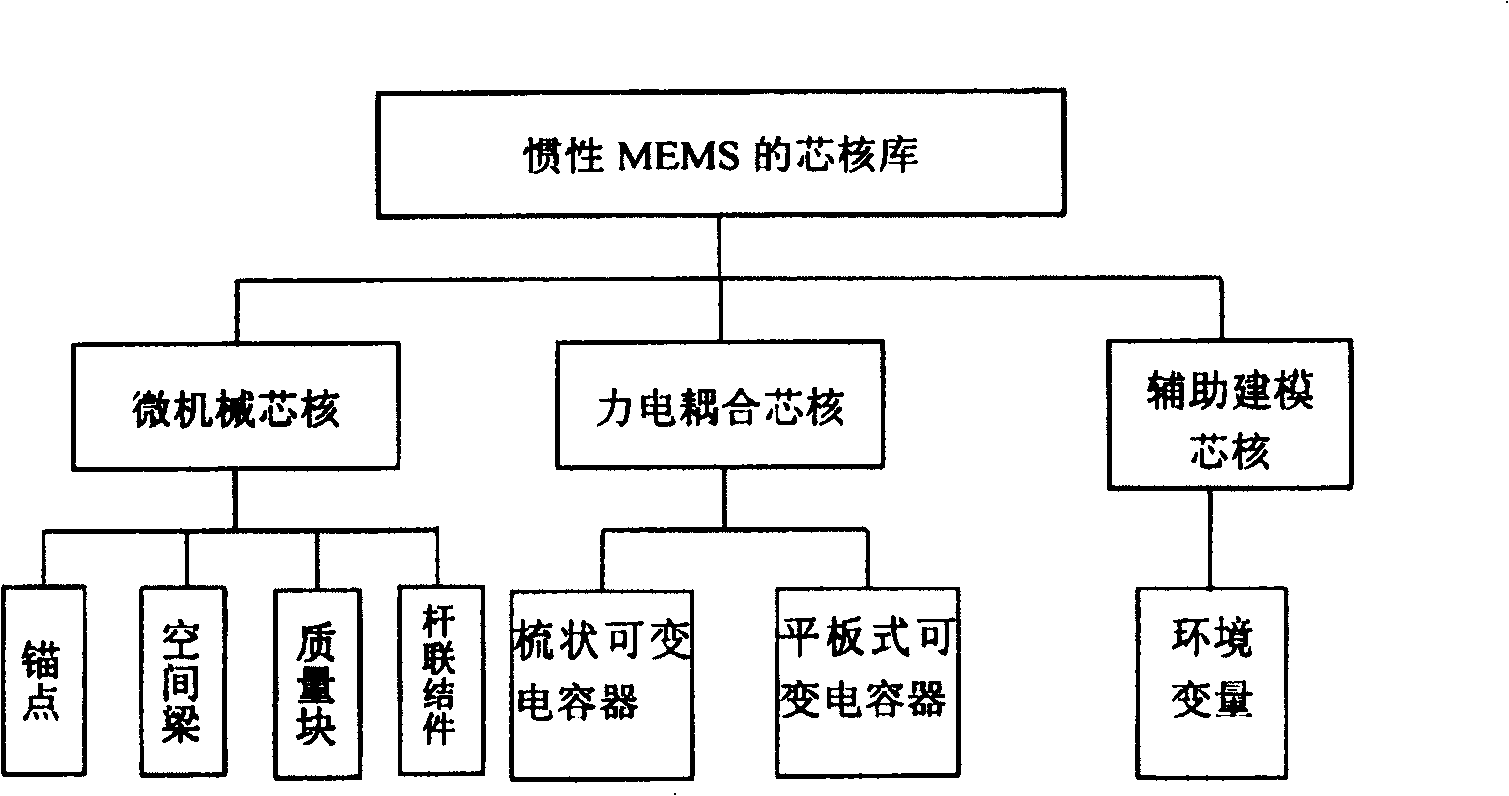

[0070] The core model of inertial microstructure is defined by taking space beam and comb structure variable capacitors as examples.

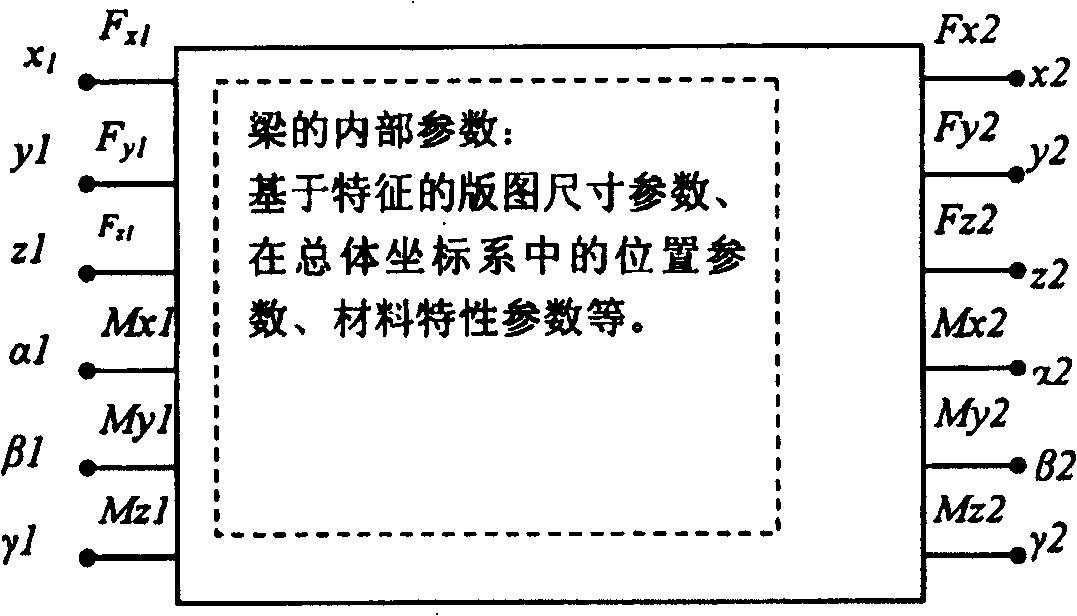

[0071] The core model of the space beam:

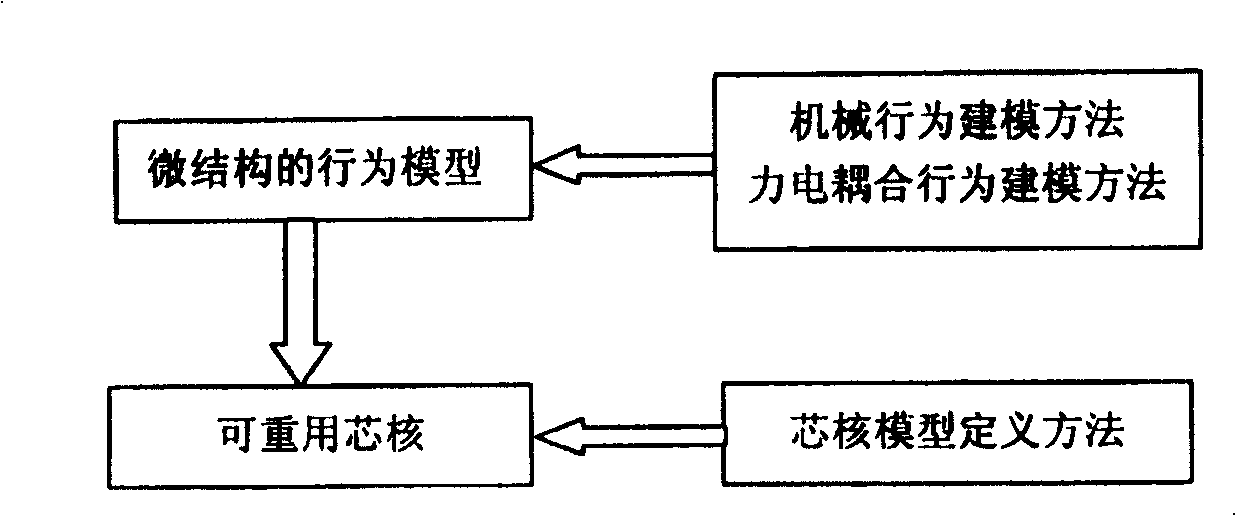

[0072] The mechanical behavior modeling method of the microstructure is used to establish its behavior model, and then its core model is defined according to the definition method of the microstructure core model.

[0073] ■In the local coordinate system

[0074] The two ends of the beam (subscripts 1 and 2 represent the two ends) are used to reflect and study the stress and deformation of the beam. Assuming that the tension, compression, bending and torsion of the beam are independent of each other, in the case of small linear displacement and angular displacement, the behavior equation of the beam in the local coordinate system is:

[0075] M ′ · ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com