Multiple caliber conduit online real-time ultrasonic thick measuring device

A multi-caliber and pipeline technology, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of fixed position of probe and water spray mechanism, etc., and achieve the effect of simple structure, high precision and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

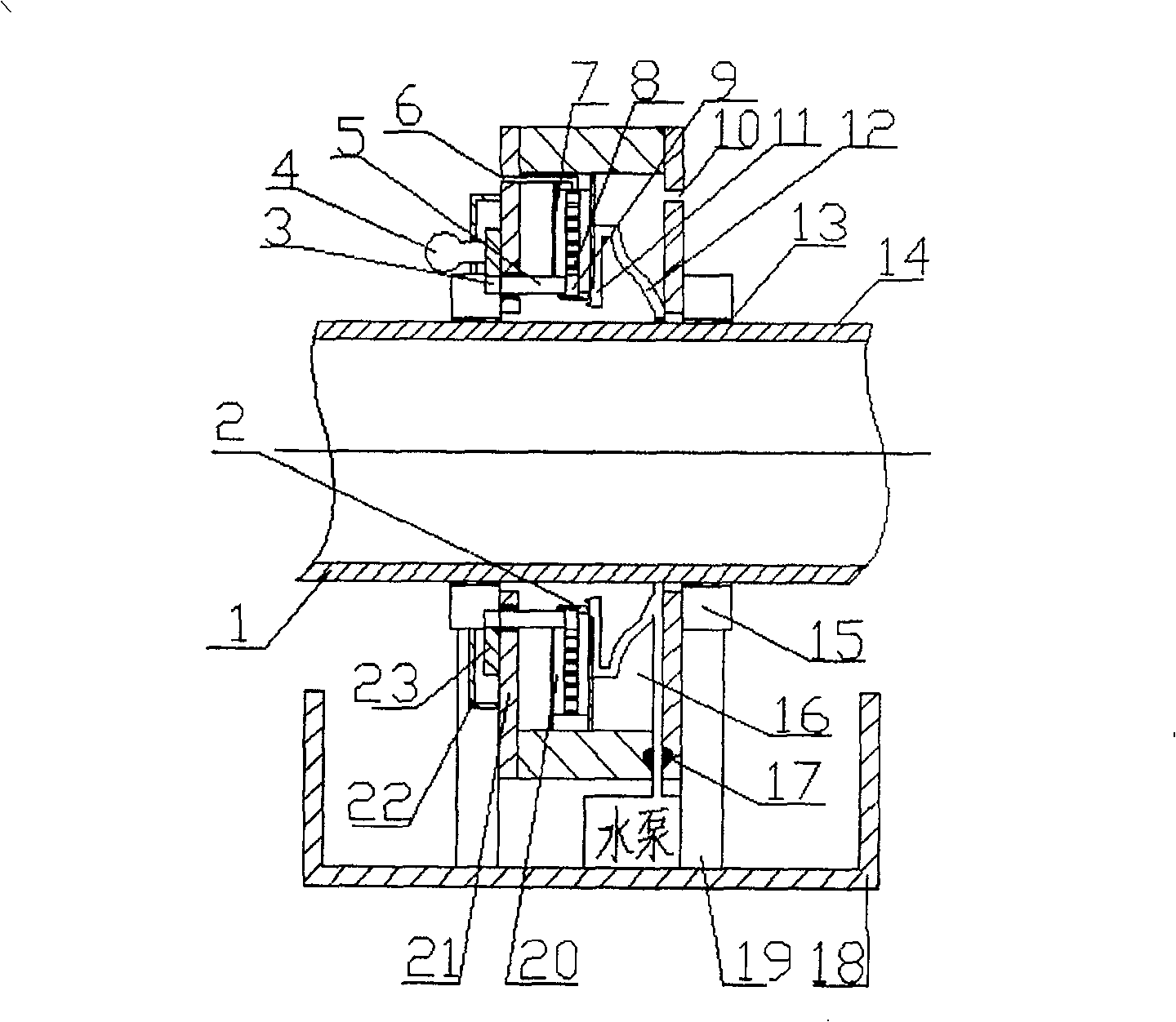

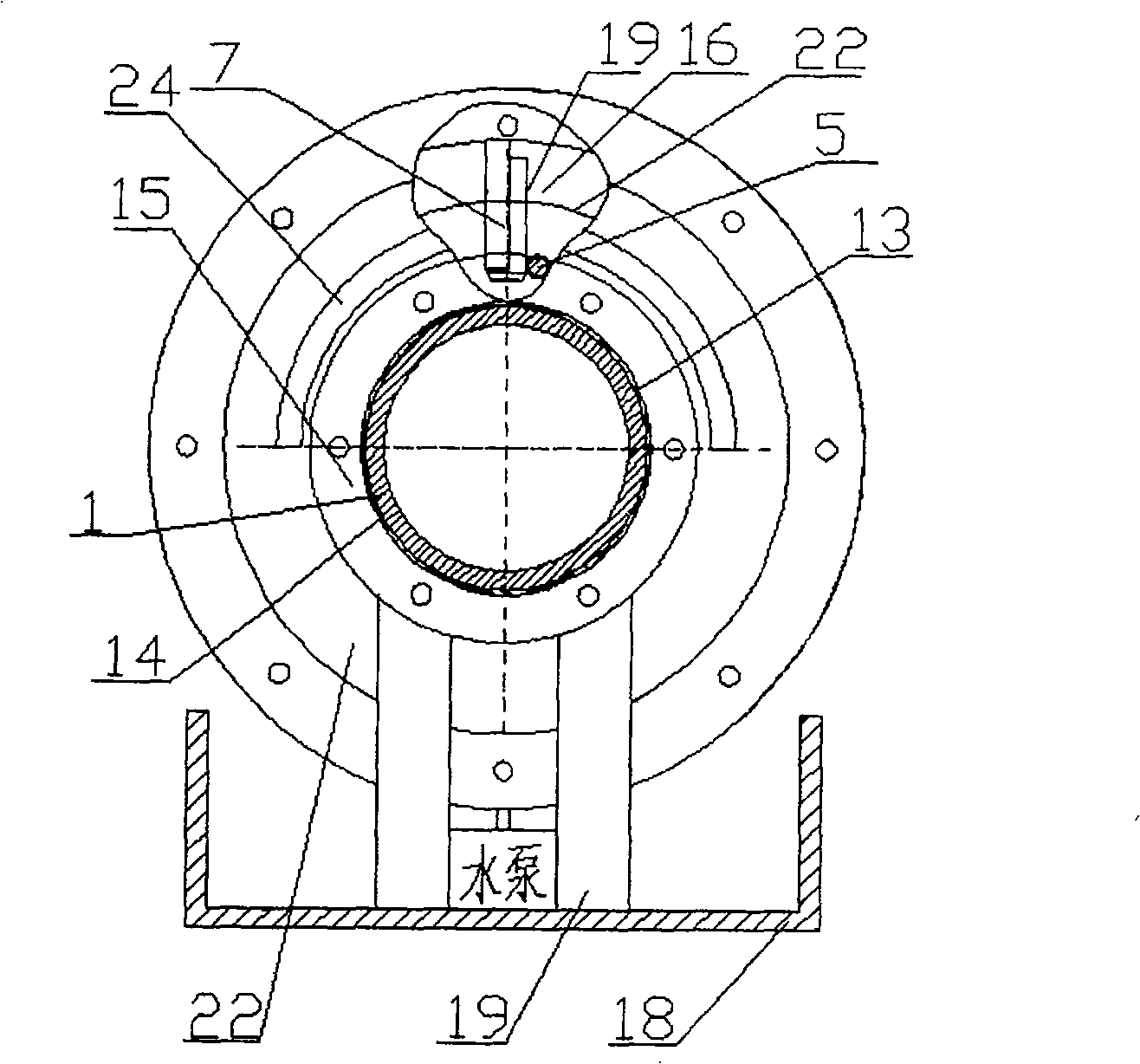

[0016] A preferred embodiment of the present invention is: see Figure 1 and figure 2 , the online real-time ultrasonic thickness measuring device for multi-caliber pipelines, including multi-channel ultrasonic probes 2 that are uniformly distributed along the circumference of the pipeline 1 and radially facing each other in pairs, and a water spray mechanism that forms the water-immersion focused ultrasonic probe 2, is characterized in that The ultrasonic probe 2 and the nozzle 11 of the water spray mechanism are connected with a linkage radial position adjustment mechanism to coordinately adjust the radial position. The structure of the above-mentioned linkage radial position adjustment mechanism is: the ultrasonic probe 2 and the nozzle 11 are fixedly installed on the inner end of the rack 8, and the rack 8 slides and cooperates with the fixed guide rail 7 with a chute to keep the ultrasonic probe 2 The axis intersects the axis of the pipeline 1 and is perpendicular to ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com