Mould processing equipment

A technology of mold processing and equipment, applied in the field of mold processing for the production of communication chassis, can solve the problem that the production volume of the mold is not very large, and achieve the effect of ensuring stability and ensuring precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

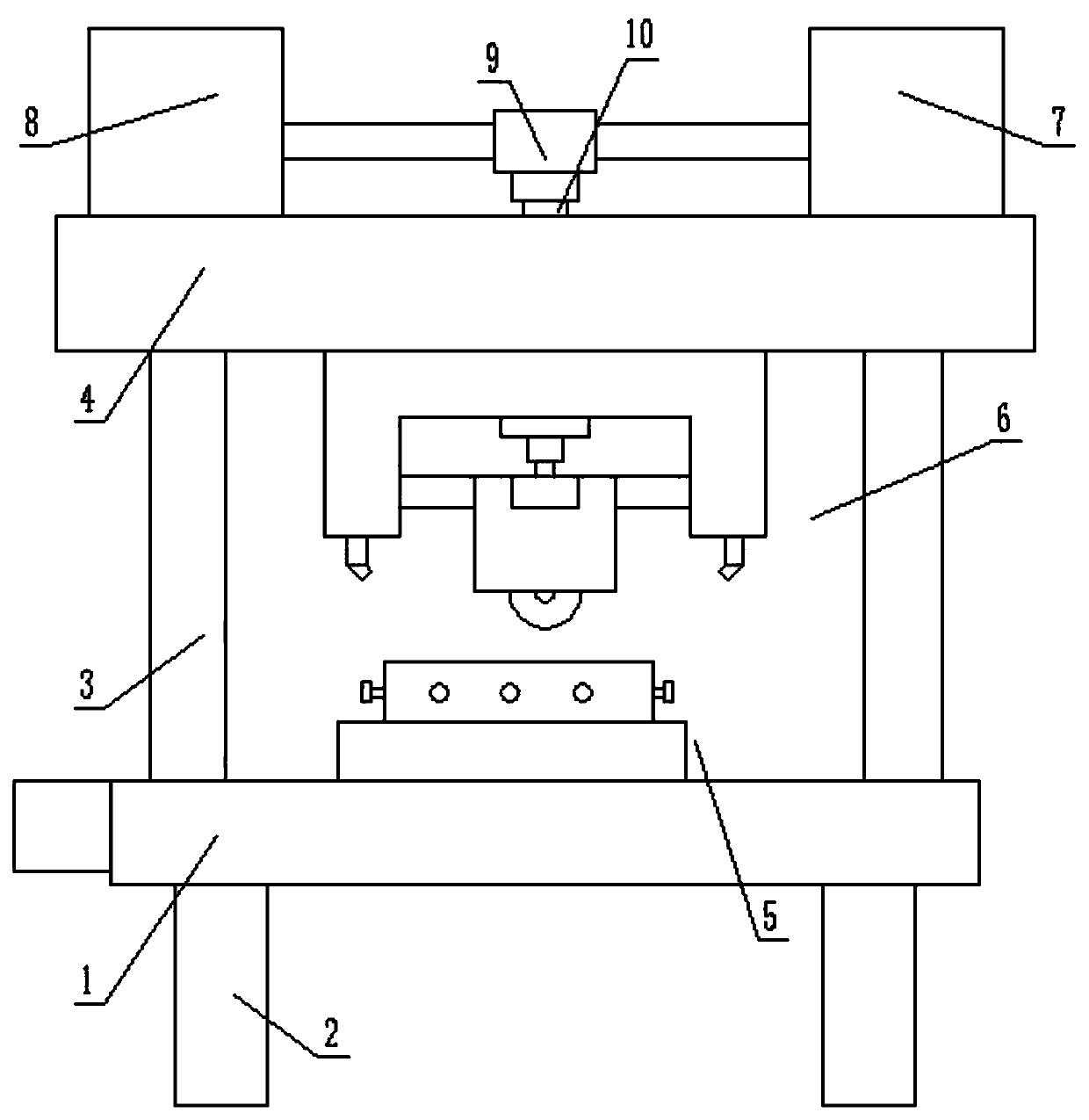

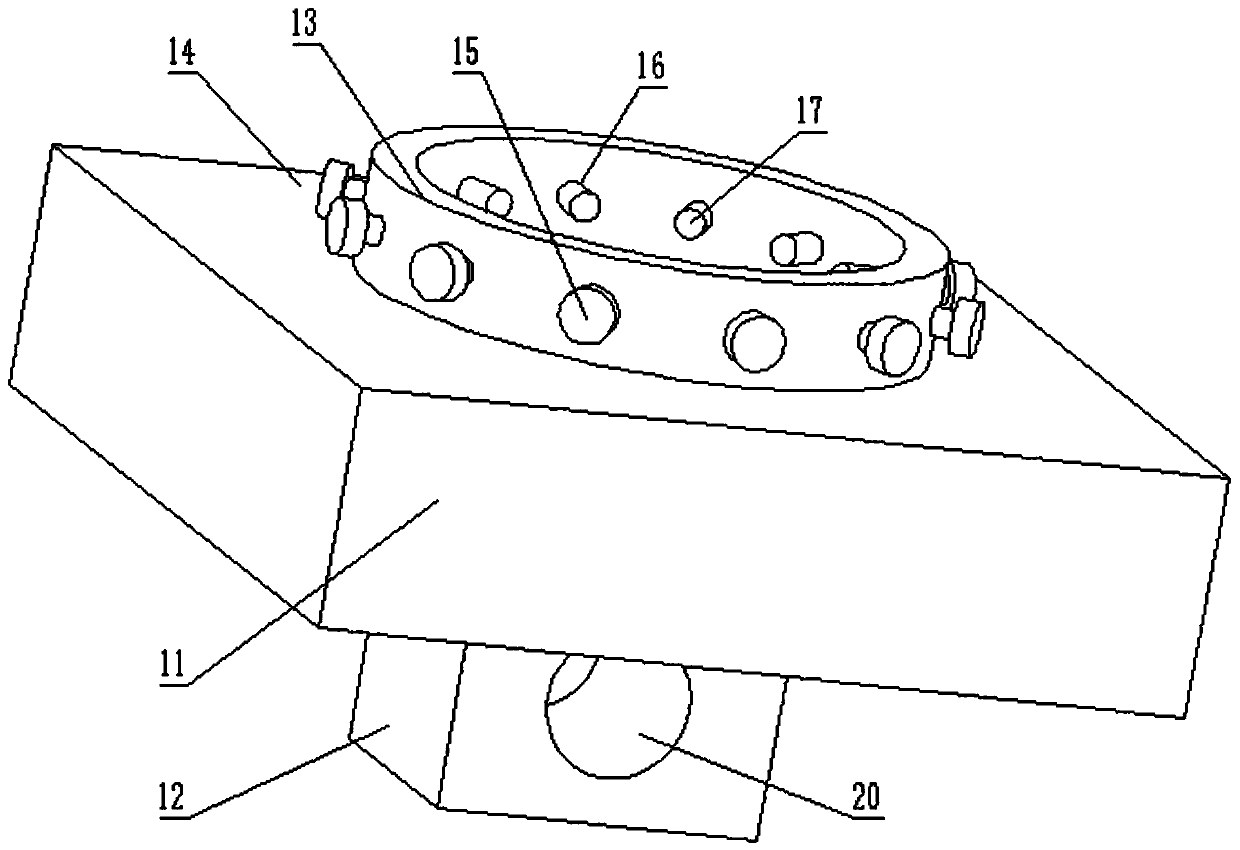

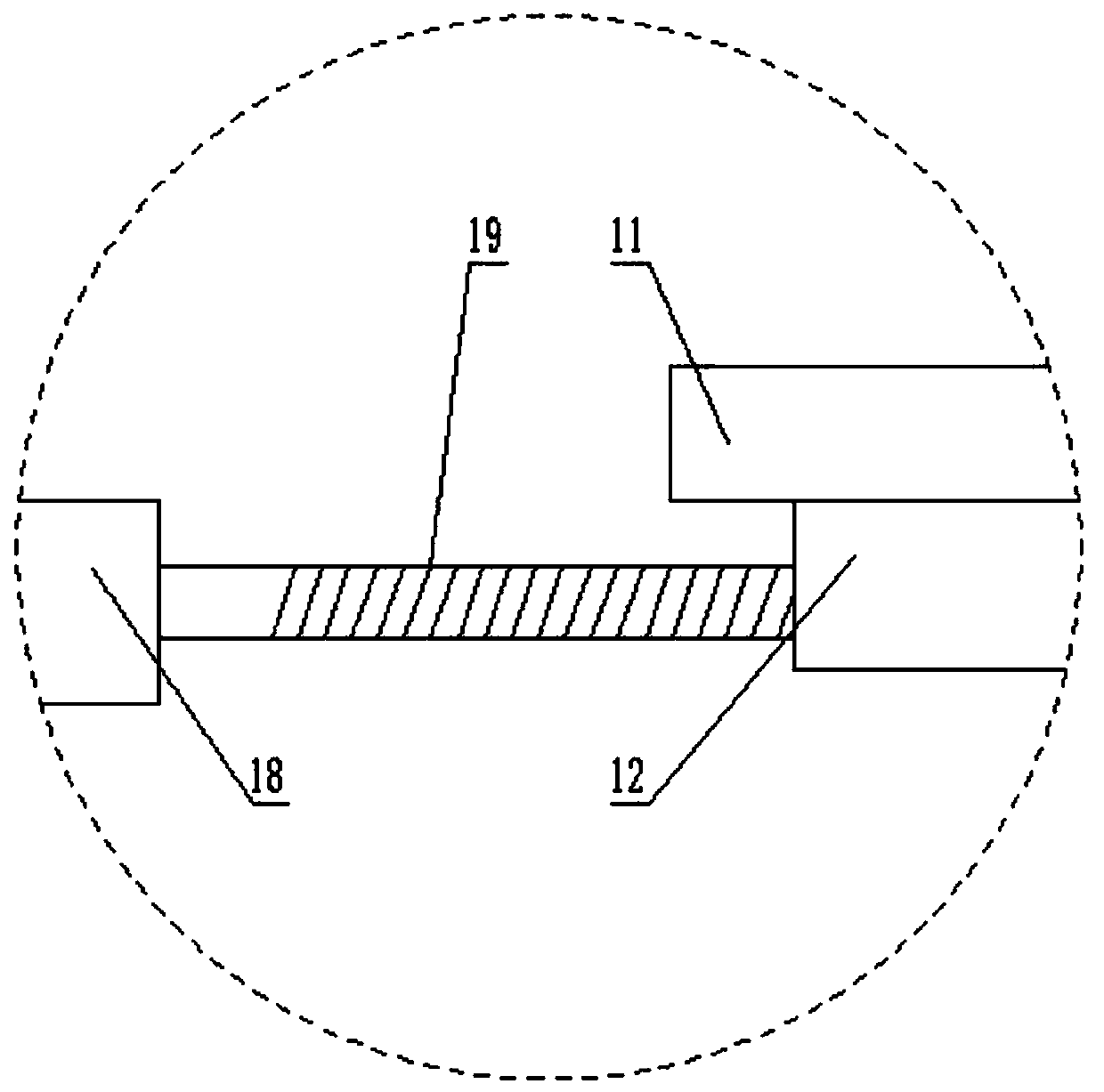

[0019] see Figure 1-4 , a mold processing equipment, comprising a machine platform 1, support legs 2, a support frame 3 and an equipment frame 4, the equipment frame 4 is located above the machine platform 1, and a plurality of support frames 3 are arranged between the machine platform 1 and the equipment frame 4 , a plurality of supporting legs 2 are provided at the bottom of the machine platform 1, a mobile lifting frame 5 is provided on the machine platform 1, and a grinder 6 is provided at the bottom of the equipment frame 4. When processing, the original to be processed is placed on the On the mobile lifting frame 5, the original is polished and polished by the grinder 6 at the bottom of the equipment frame 4, and the driving structure drives the mobile lifting frame 5 to move to ensure the stability of the equipment while ensuring comprehensive processing; The lifting frame 5 includes an integrally formed supporting platform 11 and a mobile platform 12. The mobile platf...

Embodiment 2

[0024] On the basis of Embodiment 1, in order to ensure the precision and stability of the mold processing, the bottom of the machine 1 is provided with a damping rod, which has the same number as the supporting legs 2 and is connected to the supporting legs 2 one by one. Corresponding to the fit setting, the shock absorbing rod is composed of two rubber rods and a shock absorbing spring located between the two rubber rods, which can quickly absorb vibrations and ensure the stability of the device as a whole during processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com