Semiconductor device and method of manufacturing same

A semiconductor and device technology, applied in the field of silicon-on-insulator materials, can solve problems such as lateral pnp transistor misoperation, and achieve the effect of eliminating misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

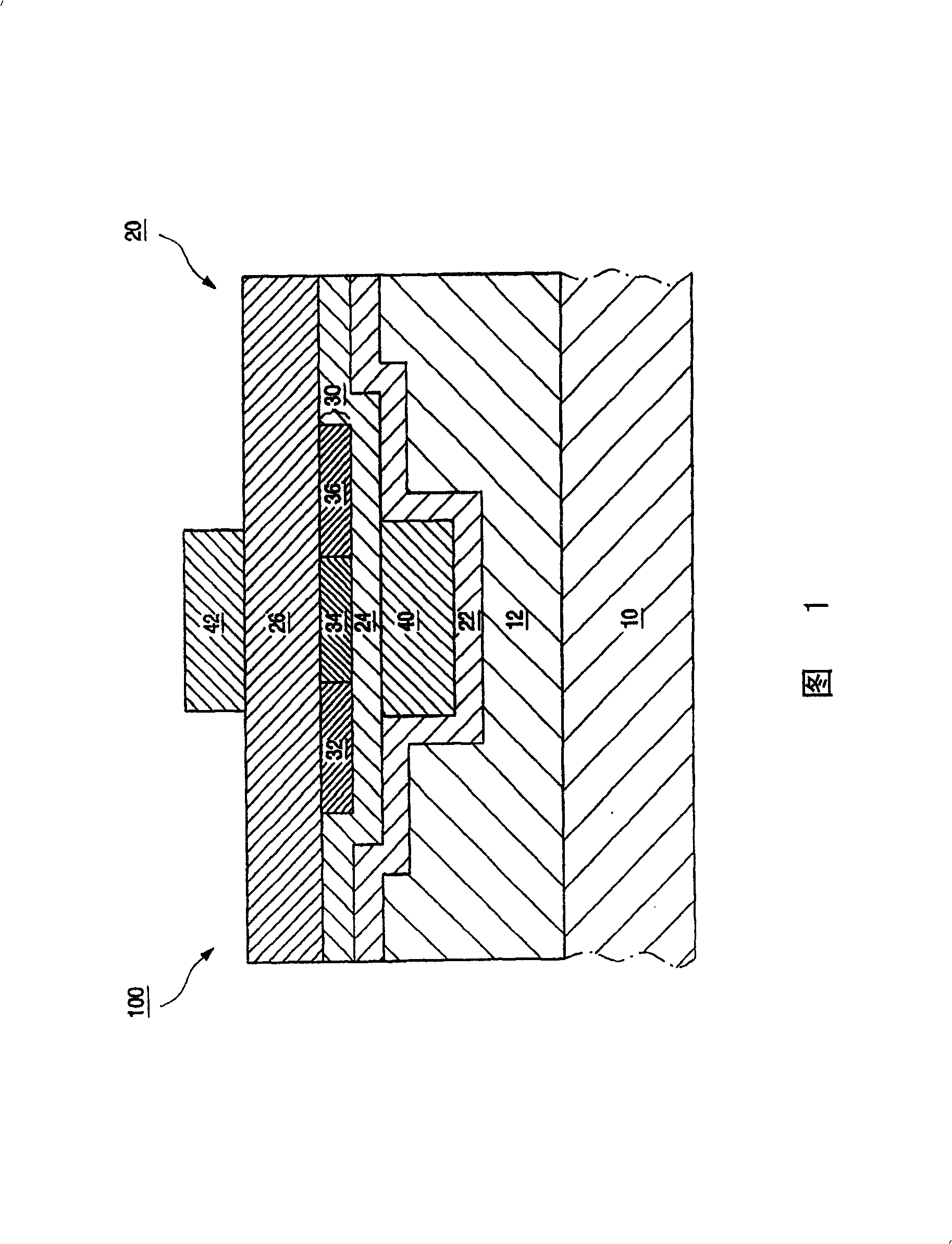

[0025] As shown in the embodiment of FIG. 1, the present invention provides a semiconductor device in the form of an SOI device 100 comprising an insulating layer 10 of dielectric material and a silicon substrate 20 disposed on the insulating layer 10. As shown in FIG. Integrated in this silicon substrate 20 is an element in the form of a bipolar pnp transistor 30, which element has a lightly doped region (in the form of an n-doped region 34) in its central region, while in each of the two lateral regions Inside one is a highly doped region (in the form of P-doped regions 32 and 36 respectively). As shown in FIG. 1, the silicon substrate 20 containing the components 30 is fixed on the insulating layer 10 by means of a fixing medium in the form of an adhesive layer 12 .

[0026] Between the insulator 10 and the n-doped region 34 of the pnp transistor 30, a planar first metallization region (in the form of a first field plate 40) is formed to serve as the lead layer of the pnp t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap