Composite excitation permanent magnet synchronous variable-speed motor

A synchronous motor, compound excitation technology, applied in synchronous motors with stationary armatures and rotating magnets, single motor speed/torque control, etc. Satisfaction and other issues, to achieve the effect of good control performance and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

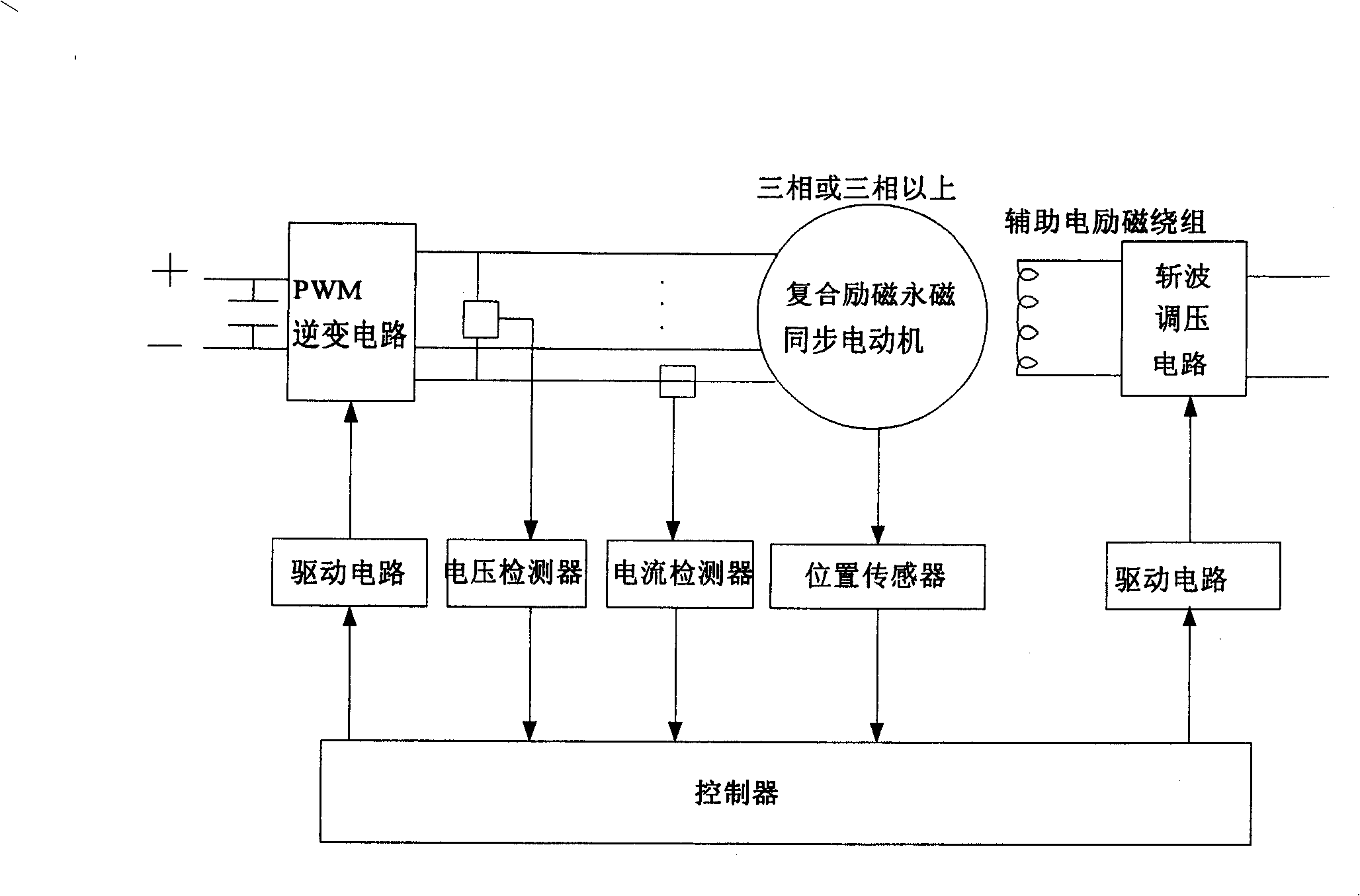

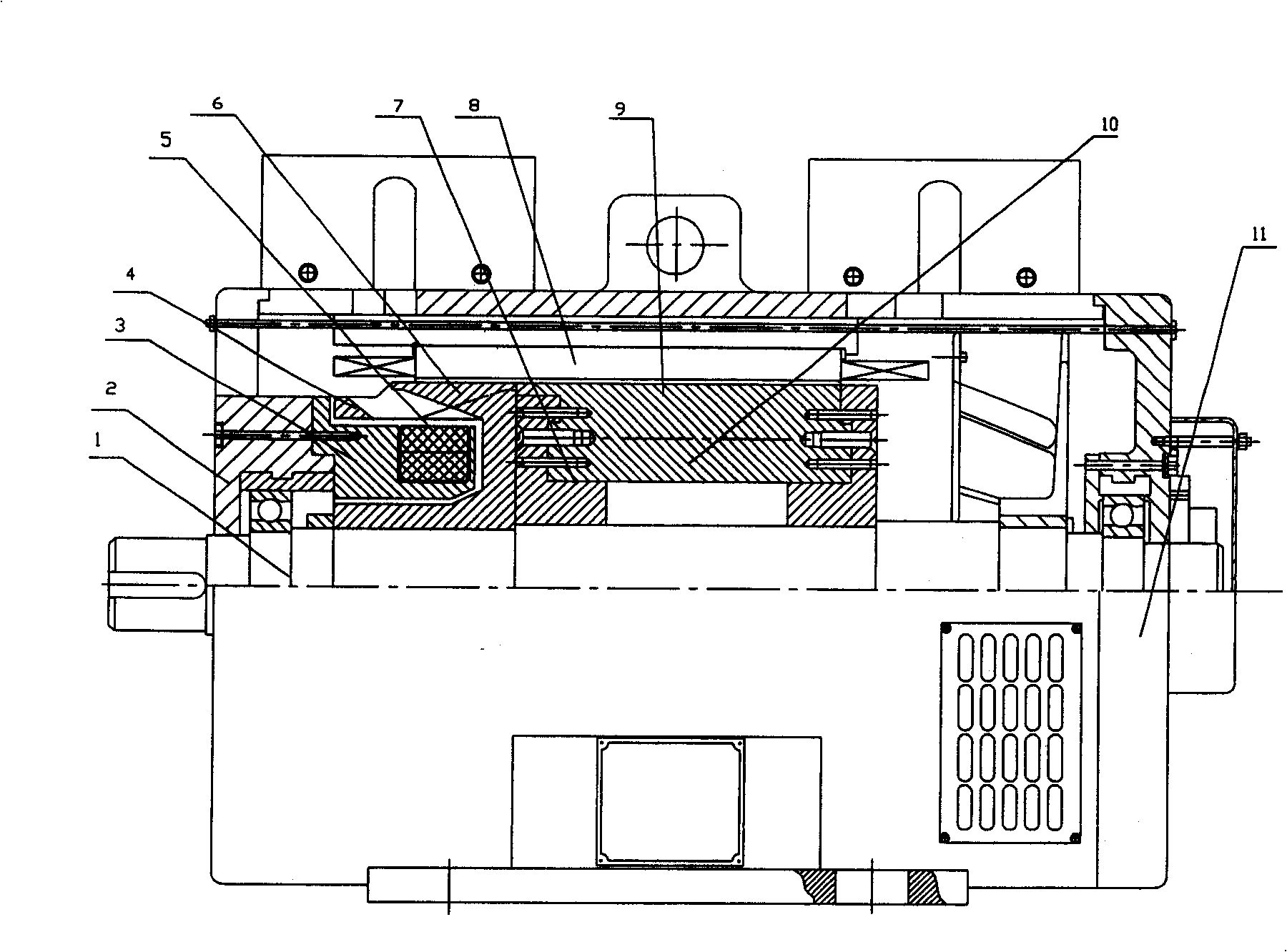

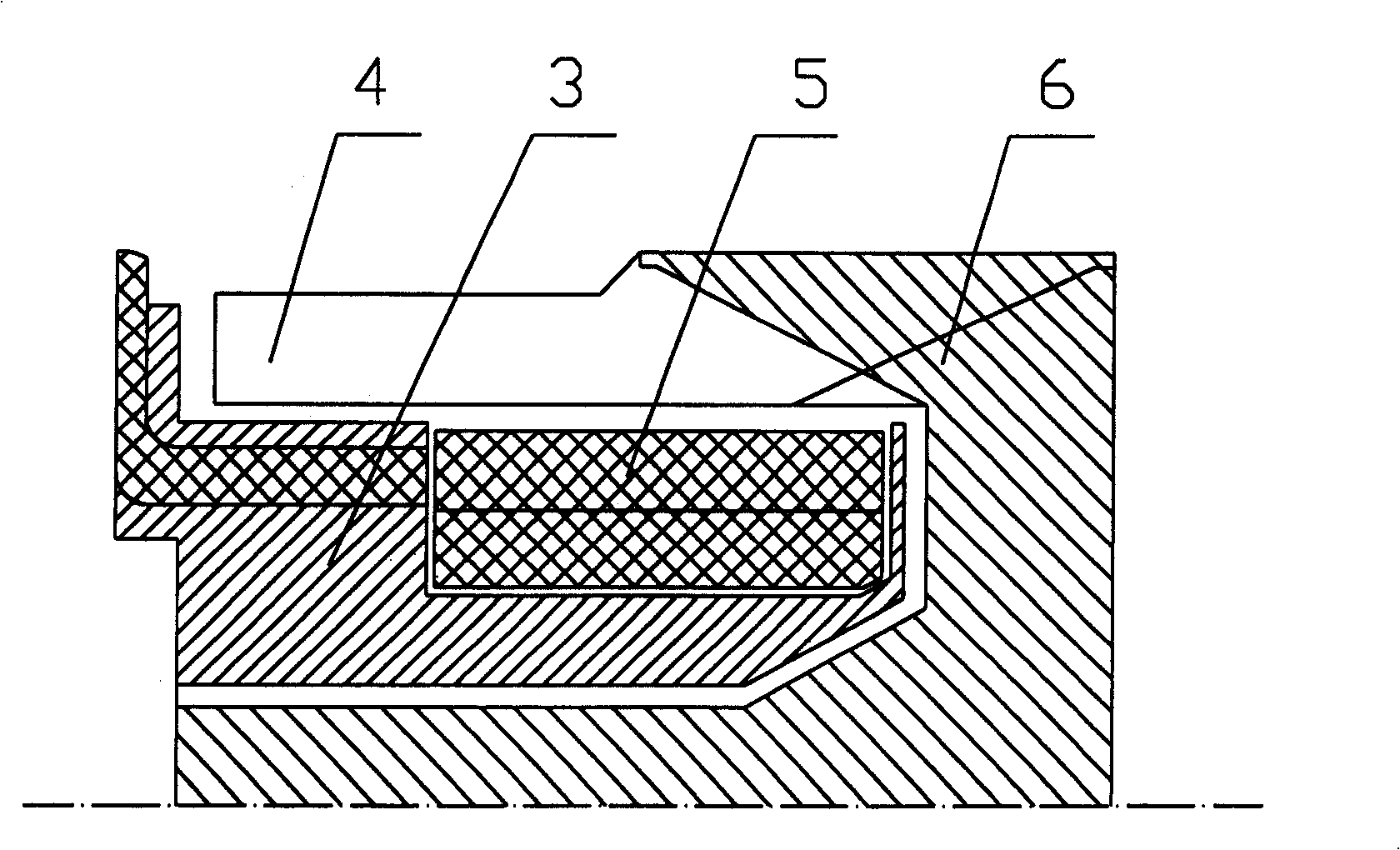

[0026] Such as figure 1 and figure 2 As shown, the composite excitation permanent magnet synchronous speed-regulating motor of the present invention includes a composite excitation rare earth permanent magnet synchronous motor and a speed control system. The composite excitation rare earth permanent magnet synchronous motor includes a rotating shaft 1, an end cover 2, and a casing 11. Armature winding 8, the shaft 1 is equipped with a rare earth permanent magnet rotor for main excitation and an auxiliary electric excitation rotor for voltage regulation, the rare earth permanent magnet rotor and auxiliary electric excitation rotor share the armature winding 8, and the magnetic potential generated is in the magnetic circuit Combined in parallel, magnetic isolation plates 7 are provided at the bottom of both sides of the rotor core 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com