Cylinder, in particular for a motor vehicle hydraulic brake system

A technology of hydraulic braking and motor vehicles, which is applied in the direction of mechanical equipment, engine components, engine sealing, etc., to achieve the effect of improving flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

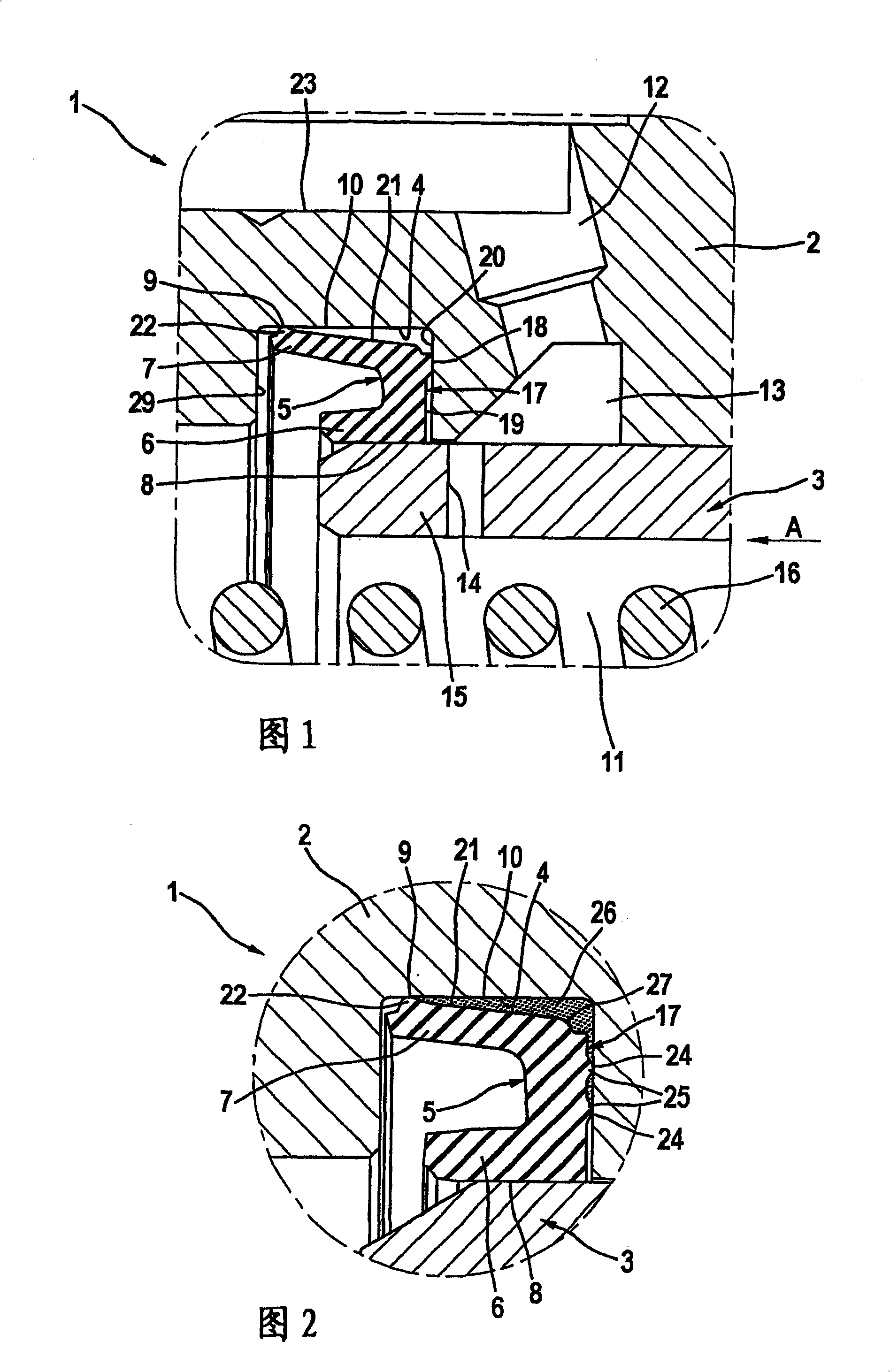

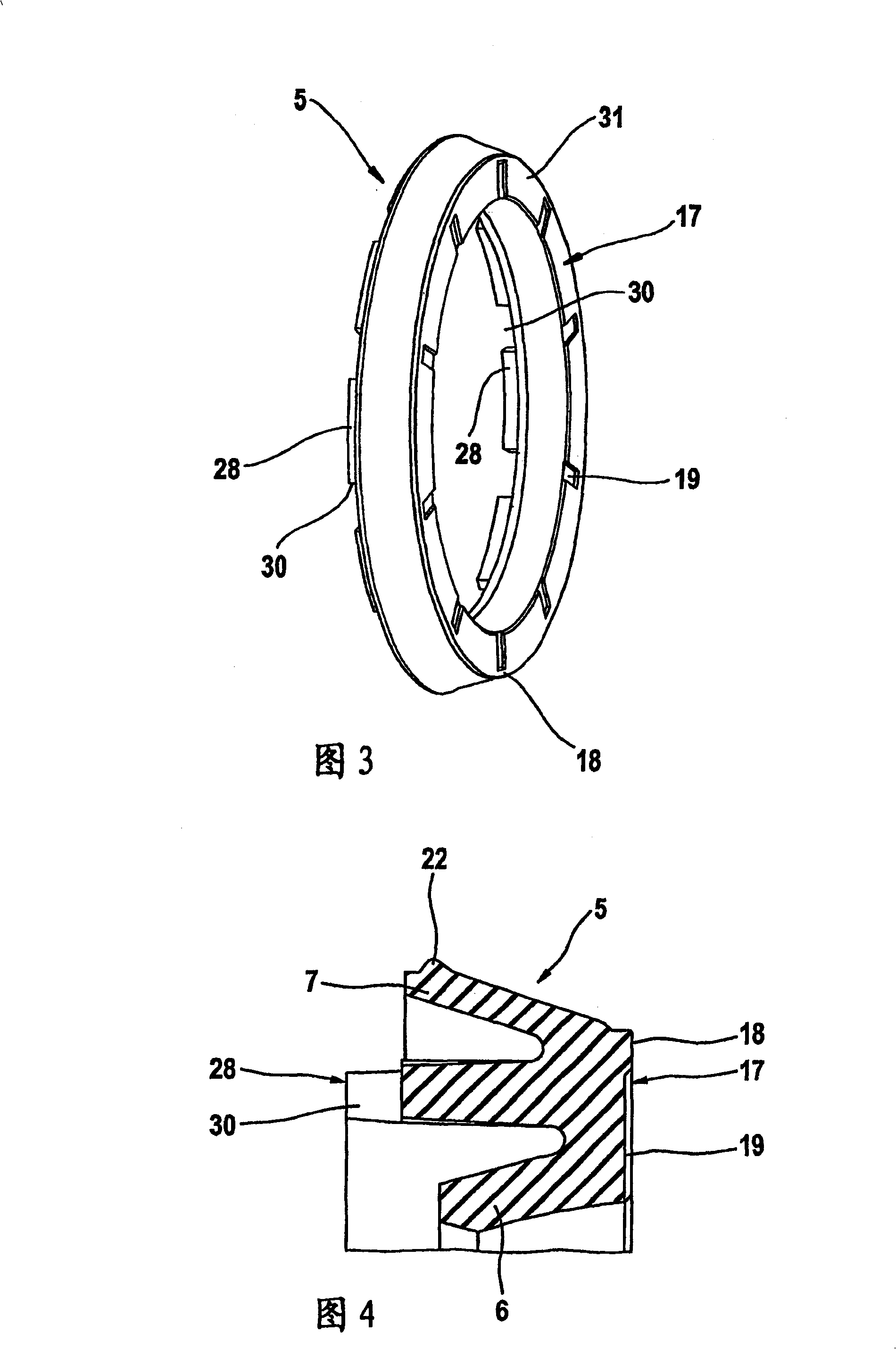

[0016] FIG. 1 shows in a partial view the components essential to the invention of a first embodiment of a cylinder designed, for example, in the form of a plunger and tandem construction for a hydraulic brake system of a motor vehicle. master cylinder 1. The way in which such a master cylinder 1 works is known in principle, so that the features essential to the invention will mainly be described. In addition, the two sequentially arranged pressure circuits of the master cylinder 1 in a tandem configuration are almost identical in structure and mode of operation, so only one pressure circuit will be described.

[0017] The pressure circuit of the master cylinder 1 shown in partial view comprises a plunger 3 which is movable in a housing 2, wherein an annular sealing ring 5 is arranged in an annular groove 4 of the housing 2 and has a dynamically stressed interior Sealing lip 6 and statically stressed outer sealing lip 7. The dynamically stressed inner sealing lip 6 bears aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com