Method for controlling chip temperature in reaction chamber for semiconductor etching process

A reaction chamber and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of silicon wafer temperature rise, rise to 80 °C, and silicon wafer etching effect deviating from the expected value. The effect of the eclipse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

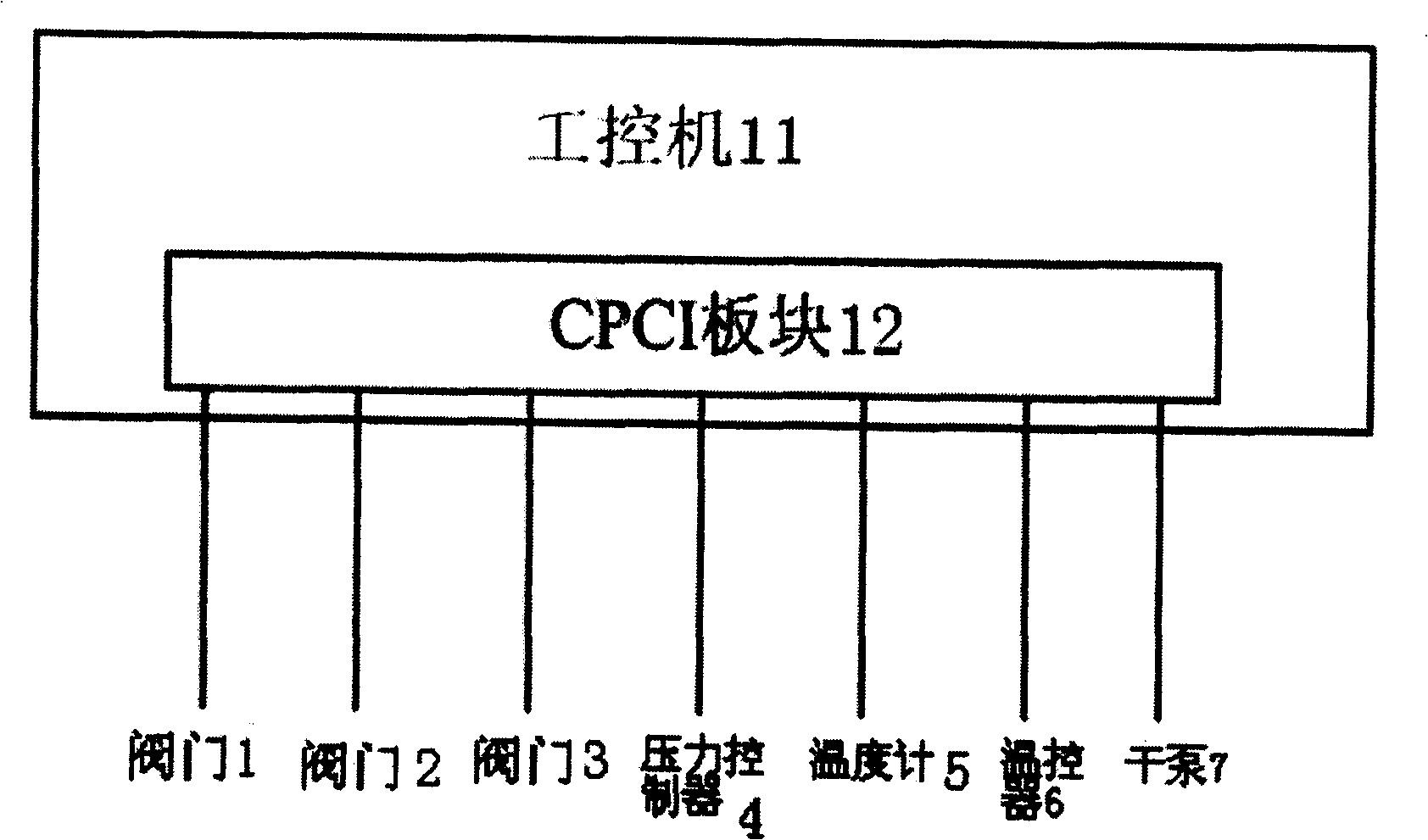

[0022] The connection diagram of the computer control equipment of the present invention is as follows figure 1 As shown, in the wafer etching process, the industrial computer 11 is connected to various controlled devices through the CPCI (Compact Peripheral Component Interconnect) block 12, including valve 1, valve 2, valve 3, and pressure controller 4. , Thermometer 5, Thermostat 6, Dry pump 7.

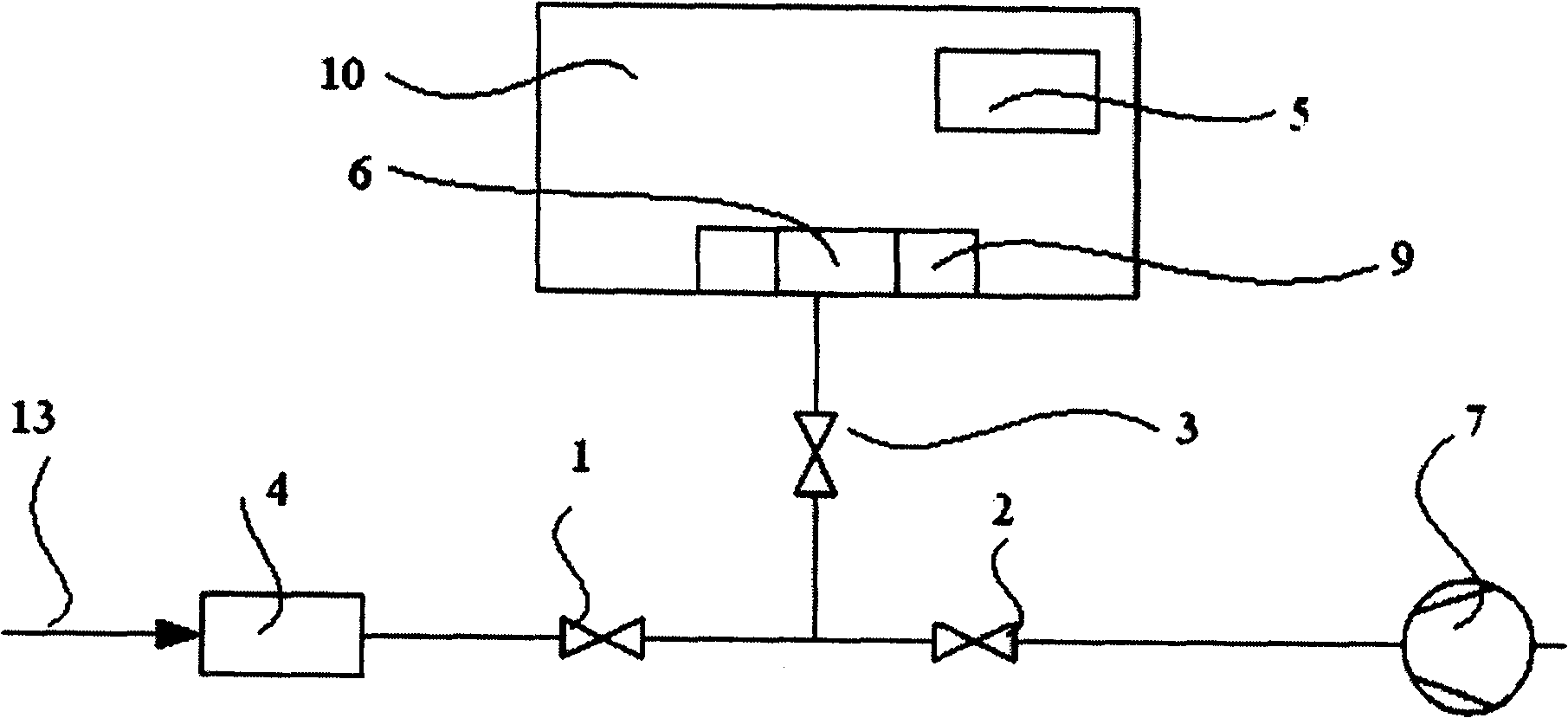

[0023] Such as figure 2 As shown, the electrostatic chuck 9 and the thermometer 5 are placed in the reaction chamber 10. The thermometer 5 can measure the temperature of the reaction chamber 10 in real time. The thermostat 6 is placed at the entrance of the reaction chamber 10, and the gas enters the reaction chamber. At 10 o'clock, the temperature will be heated by the thermostat 6 to a predetermined value.

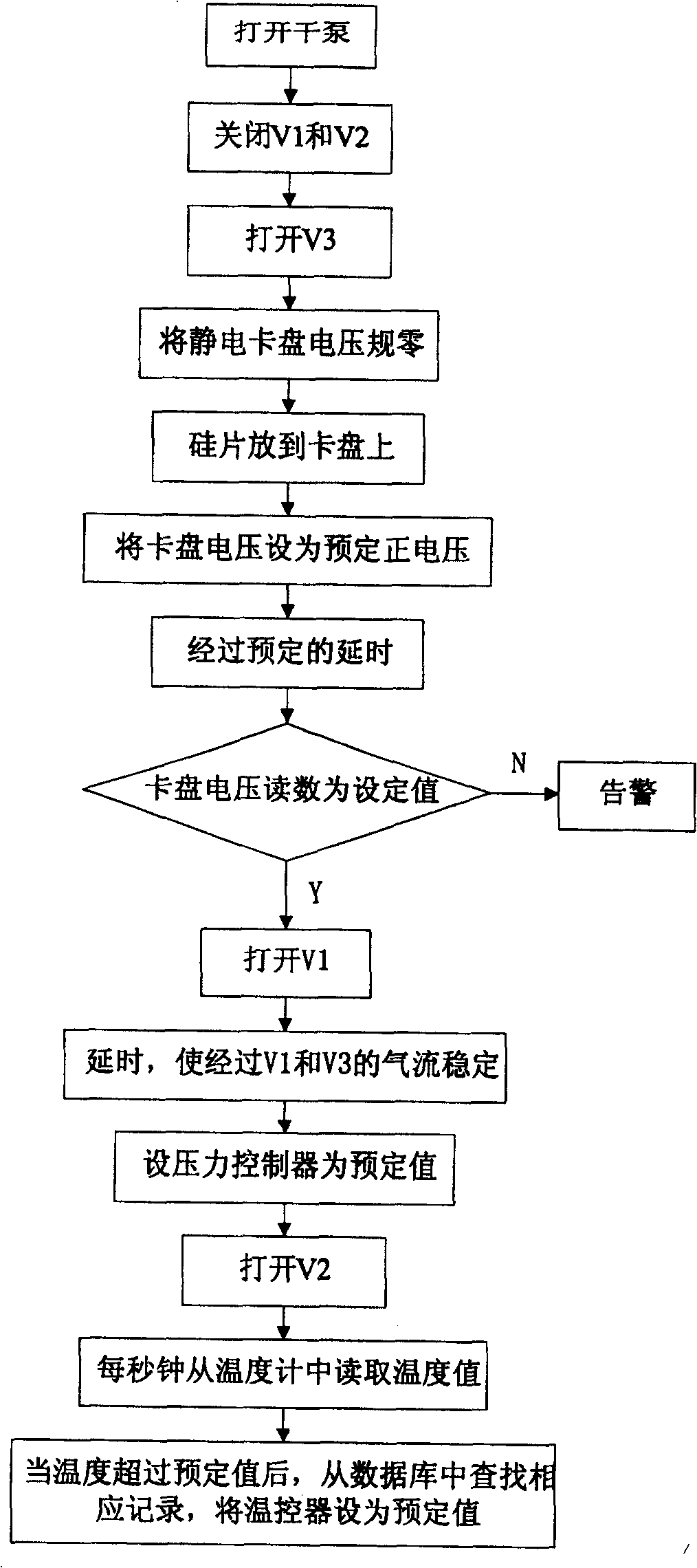

[0024] Such as image 3 As shown, at the beginn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com