Engine-driven working machine

An engine-driven, working machine technology, applied in the directions of engine components, engine cooling, engine frame, etc., can solve problems such as large load, and achieve the effect of reducing impact load, preventing excessive deformation, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

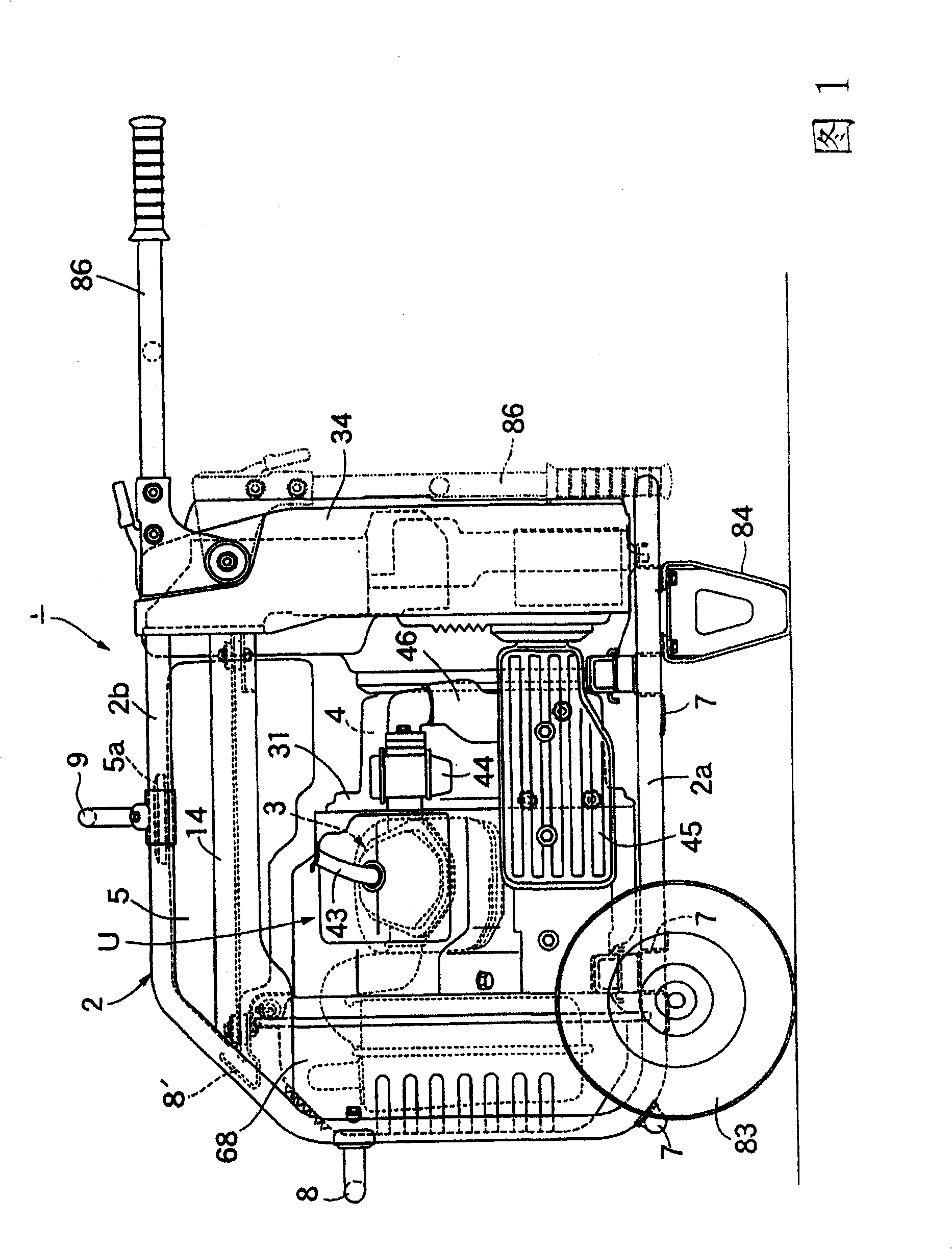

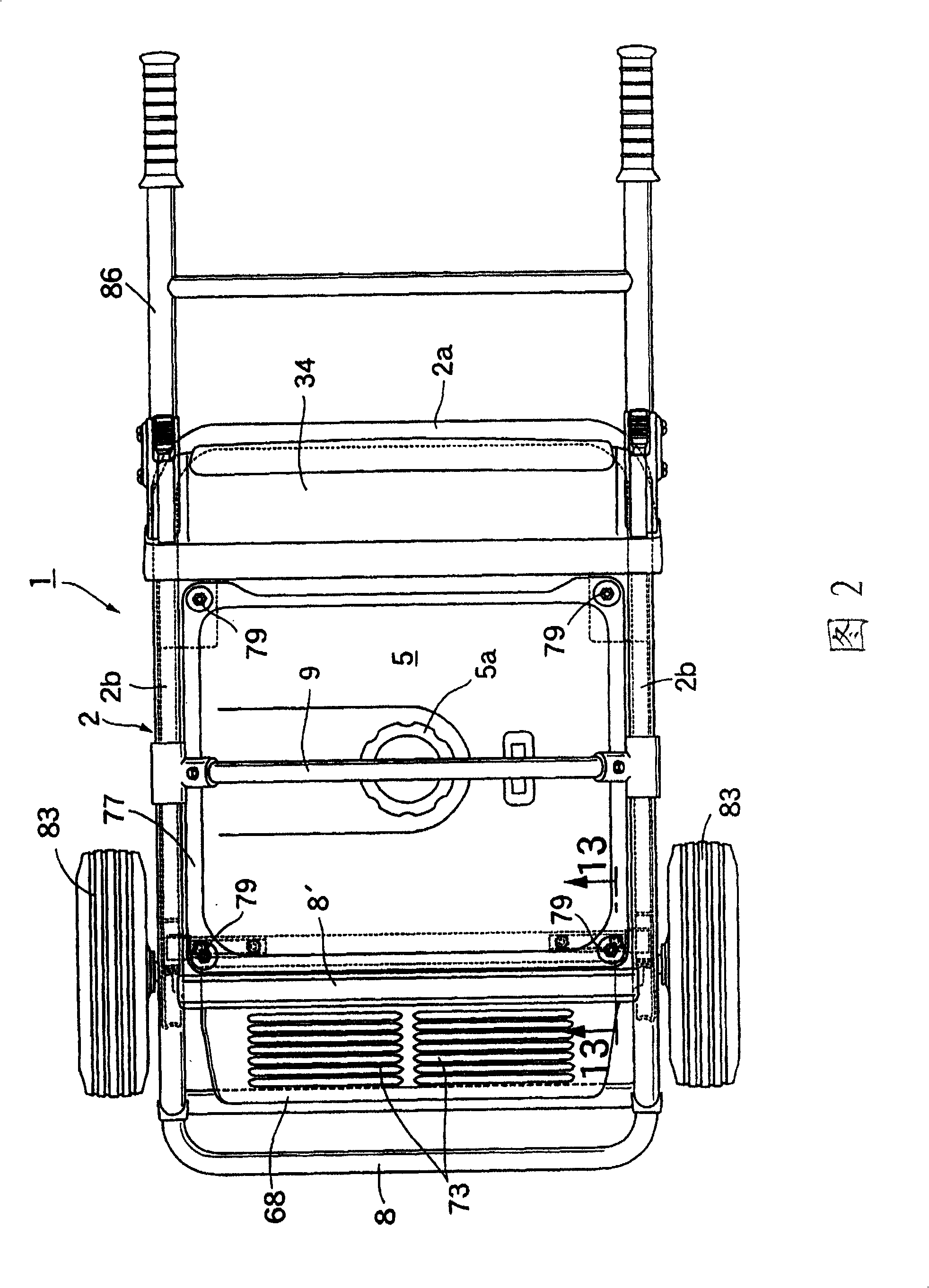

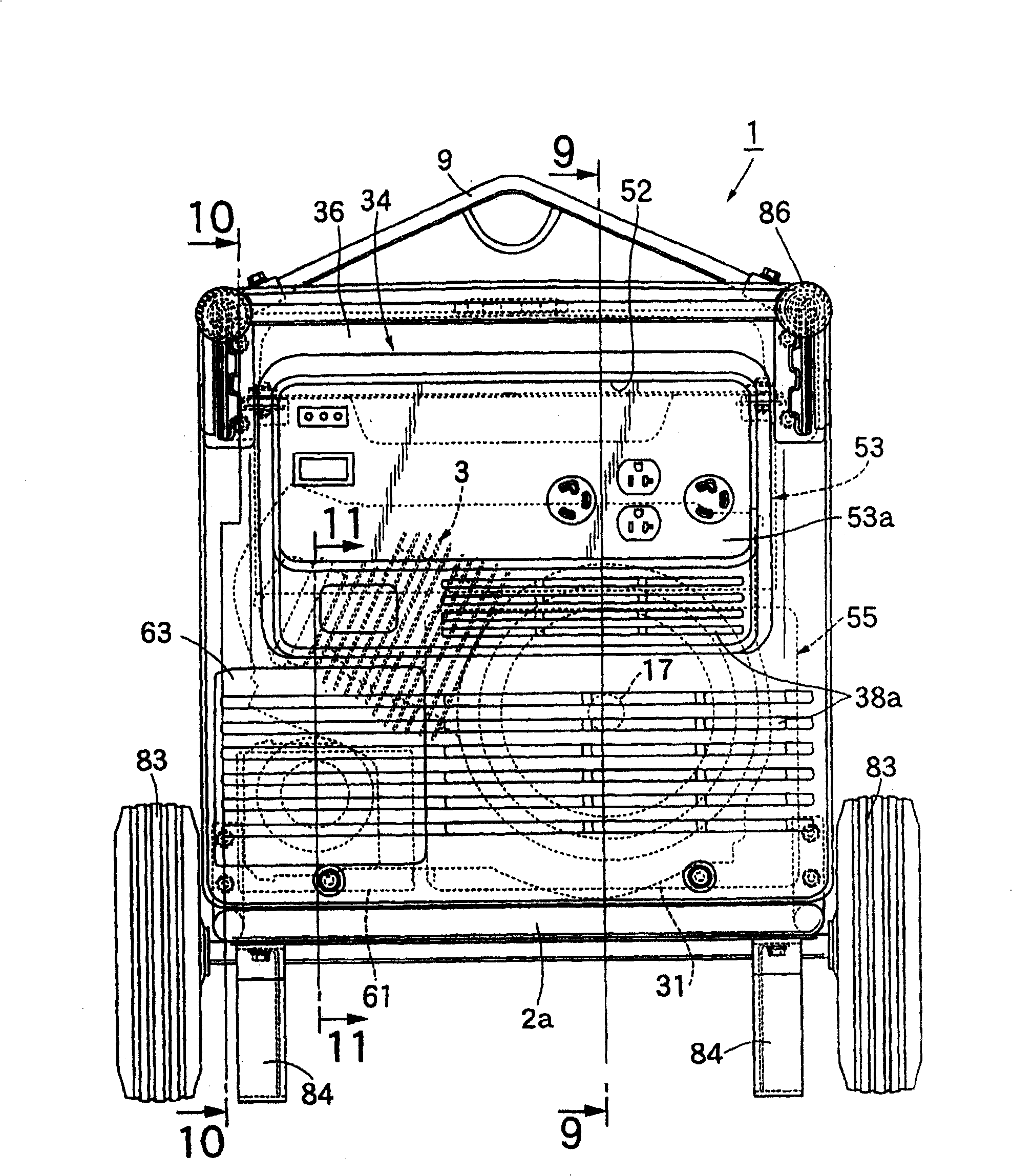

[0061] First, in Figure 1~ image 3 Among them, the engine-driven generator 1 as the engine-driven working machine of the present invention includes: a frame 2; a working unit U composed of an engine 3 and a generator 4 and elastically supported by the frame 2; fuel tank 5 in the upper part of 2; control unit 53 for engine 3 and generator 4.

[0062] Figure 1~ image 3 And as shown in FIG. 8, the frame 2 is constituted to include: a bottom frame 2a obtained by bending a steel pipe into a U-shape; It is bent horizontally and forms a U-shape together with the left and right sides of the bottom frame 2a.

[0063] A plurality of lower cross members (cross members) 7, 7 ... connected between the left and right sides are provided on the bottom frame 2a, and a connection is provided between the upper parts of the vertical sides of the two side frames 2b, 2b. The middle cross member 8 of the two side frames 2b, 2b is provided with an upper cross member 8' connecting the inclined corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com