Vacuum cleaner comprising an elastic bumper strip

A vacuum cleaner and elastic technology, applied in the direction of vacuum cleaners, cleaning equipment, household appliances, etc., to achieve good scratch protection and scratch prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

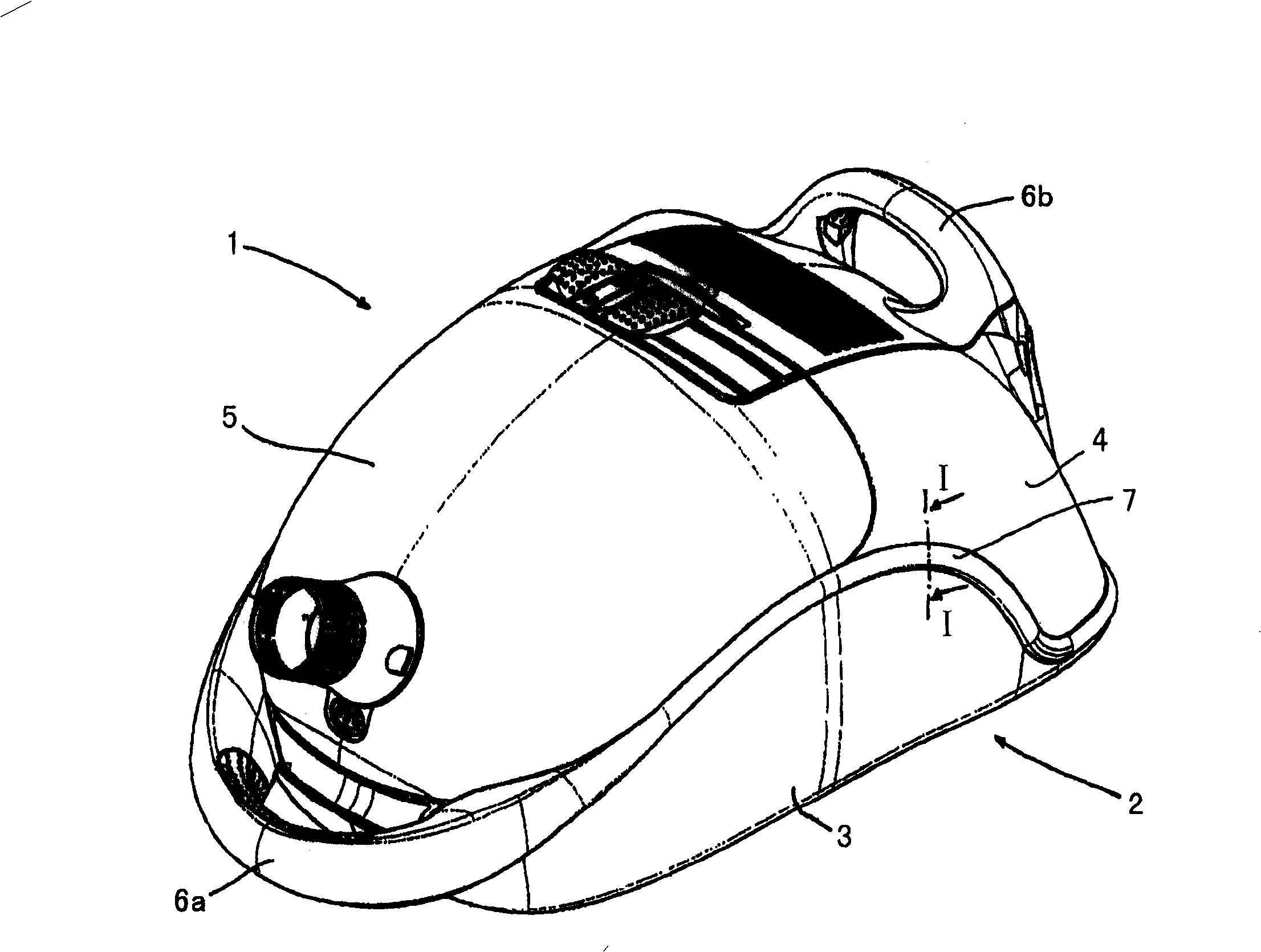

[0024] figure 1 A perspective view of a vacuum cleaner 1 is shown. The vacuum cleaner 1 has a housing 2 which is formed from a first housing part 3 and a second housing part 4 . The first housing part 3 is a lower housing and the second housing part 4 is an upper housing. A cover 5 is rotatably supported on the upper housing (housing part 4). The cover 5 closes a dust chamber arranged in the housing 2, in which a dust collector (not shown) is accommodated. A blower group not shown is housed below the upper casing (housing part 4).

[0025] A front end of the vacuum cleaner 1 has a first handle 6a. The handle 6a is curved in an arc and is connected at both ends to the first housing part 3 . A second handle 6b is attached to the outer surface of the upper housing (housing part 4) in the region of the rear end of the vacuum cleaner 1. The first housing part 3 and the second housing part 4 are designed in shell form and joined together along a dividing line.

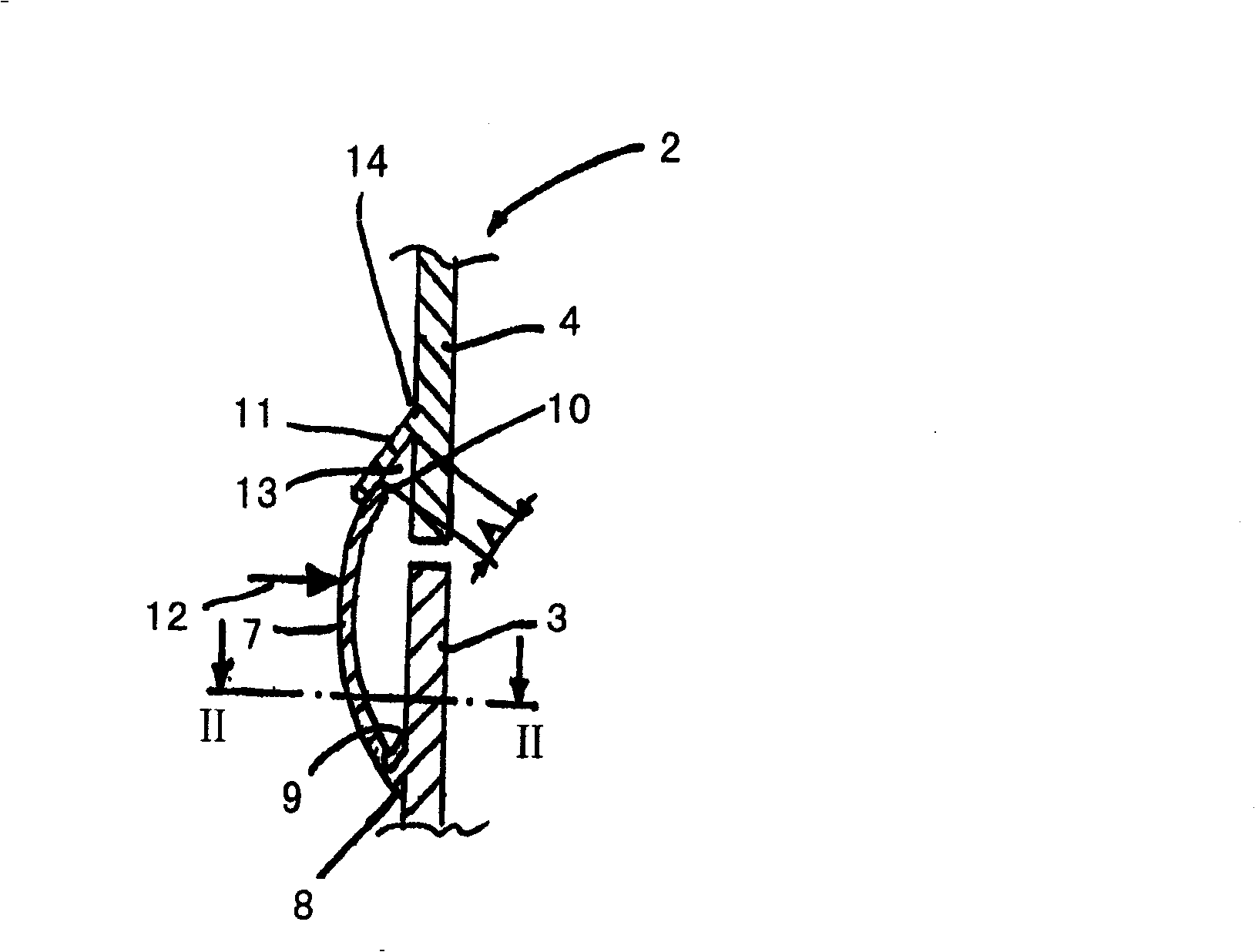

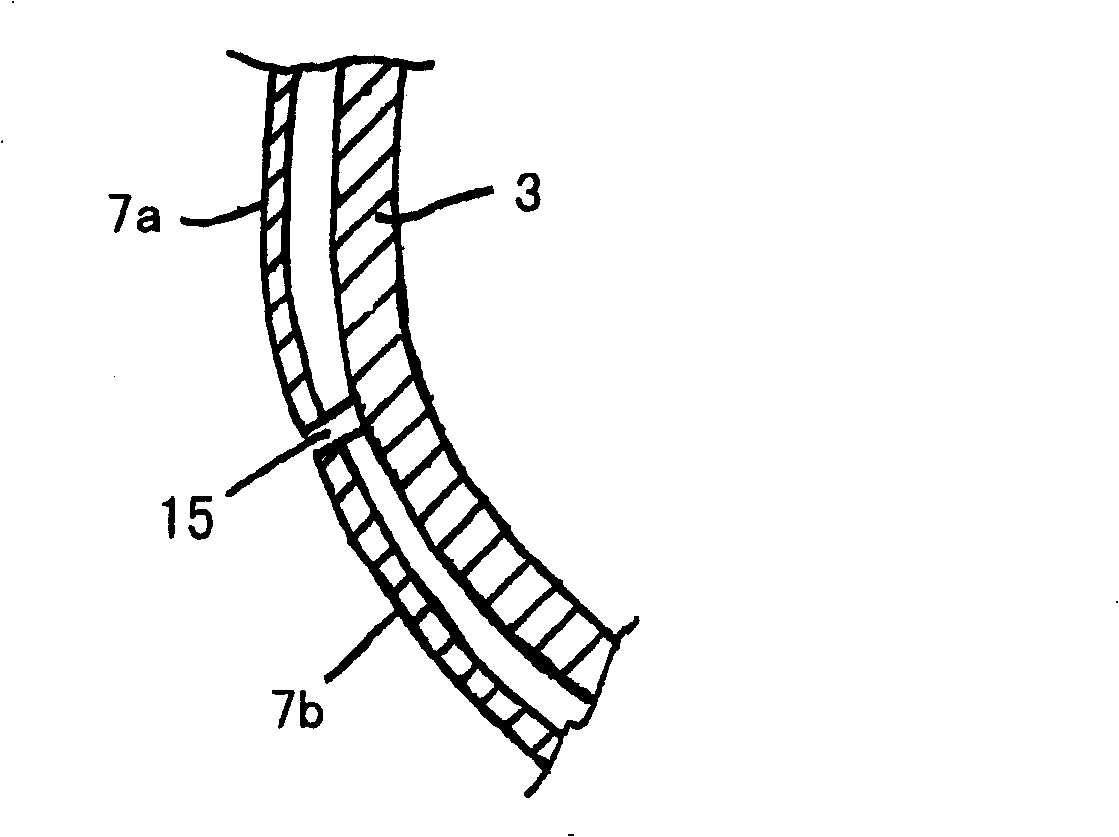

[0026]A crash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com